Risk Management

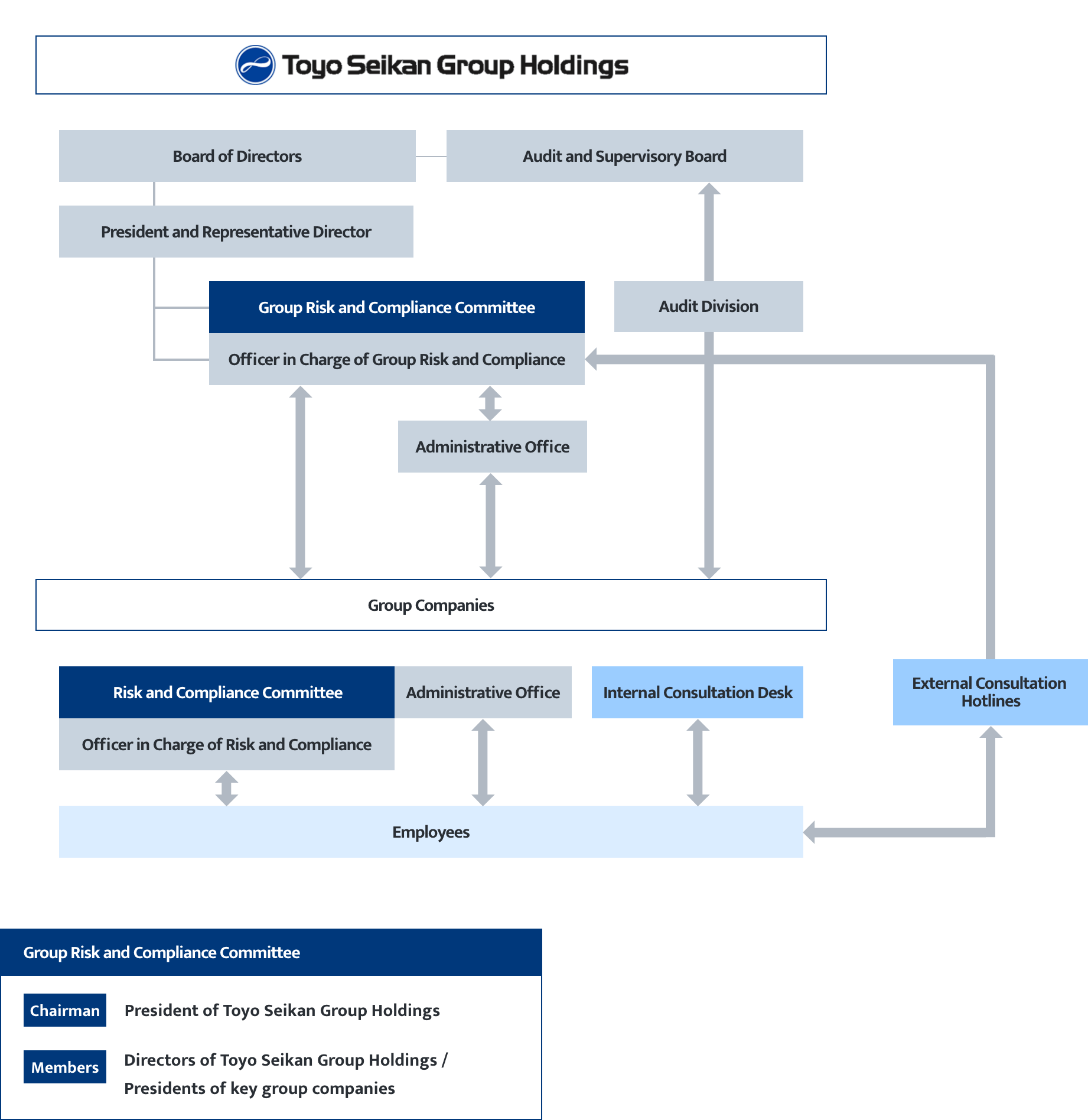

Risk Management System

We have been performing risk management based on the “Rules for Group Risk and Crisis Management.”

The Group Risk and Compliance Committee and other relevant parties check the status of the group-wide risk management and take improvement and preventive measures.

Each group company has its own framework to promote risk management, under which it formulates the basic policy and plan of its risk management and conducts a review of its company-wide risk management status.

Risk and Compliance Framework

- This chart is scrolled

Enhancing Risk and Crisis Management Framework

To address risks and crises that may affect the Group and to prevent risks that could disrupt our ongoing business, we have established the Risk Management Committee as an organization to strengthen group’s risk and crisis management structure. We have also established the Group Risk and Compliance Committee to oversee risk and crisis management and compliance across the Group. In addition, we have set up the Risk Management Administration Office as the secretariat for these committees. Both committees are responsible for verifying information related to significant risks and implementing improvement and preventive measures. Furthermore, in order to stabilize the management base, Toyo Seikan Group Holdings and its group companies individually develop crisis management rules and crisis response manuals and summarize their risk management situation under each management system.

Moreover, the companies reinforce their risk management systems based on their business continuity plans (BCPs), which have been formulated to quickly resume and maintain operations in the event of a crisis.

Addressing COVID-19 Pandemic

In addressing the COVID-19 pandemic, we focus primarily on preventing infection and ensure the health and safety of all stakeholders, including employees and their families, suppliers and customers. To prevent the spread of COVID-19, we hold a group-wide COVID-19 crisis management committee when required. We are also taking comprehensive measures for the entire group, including foreign subsidiaries, by sharing information about the current situation of infection and governmental measures through the Group’s internal database on a daily basis.

On May 8, 2023, the Japanese government reclassified COVID-19 from Category 2 to less-severe Category 5 of the five levels of legally designated infectious diseases. Following the government policy, we have suspended most of our preventive measures; however, we are maintaining certain measures to control the spread of COVID-19 and to protect individuals at high risk of infection. In the event of a resurgence of COVID-19, we will strengthen our infection control measures again, as necessary.

Activities Planned for FY2023

We will place high priority on the following five items in the Group’s risk and crisis management activities for the current year.

- Implement risk management activities (including BCPs)

- Conduct risk and crisis response drills

- Formulate and disseminate our risk management policy

- Take measures after the re-classification of COVID-19 as Category 5

- Raise managers’ awareness of harassment and abuse

Organizations and Significant Risks of Operating Companies

Each operating company of the Group has established a risk management organization to prevent the occurrence of risks, and to resume normal operations as soon as possible if a risk event occurs.The risk management organizations identify significant risks that could obstruct business operations, and take responsibility for addressing such risks.

| Company | Potential significant risk |

|---|---|

| Organization | |

| Toyo Seikan |

Operation and management / Finance and accounting / Debt collection / Natural disaster and accident / Compliance / Information security / Manufacturing and quality / Environment / Country |

| Risk & Compliance Committee | |

| Toyo Kohan |

Compliance / Manufacturing,facilities,quality / Sales / Safety,hygiene,disaster prevention / Environment / Information |

| Risk Management Committee | |

| Tokan Kogyo |

Compliance / Manufacturing and quality / Environment / Finance and accounting / Information security / Natural disaster and accident / Country / Operation and management |

| Risk & Compliance Committee | |

| Nippon Closures |

Compliance / Significant loss(due to natural disasters and accidents) / Information security / Quality / Environment / Country |

| Risk & Compliance Committee | |

| Toyo Glass |

Compliance / Natural disaster and accident / Environment / Quality / Information security / Debt collection / Country / Food safety |

| Risk & Compliance Promotion Committee | |

| Mebius Packaging |

Operation and management / Finance and accounting / Debt collection / Natural disaster and accident / Compliance / Information security / Manufacturing and quality / Environment / Country |

| Risk & Compliance Committee |

Risk Management Activities of Group Companies

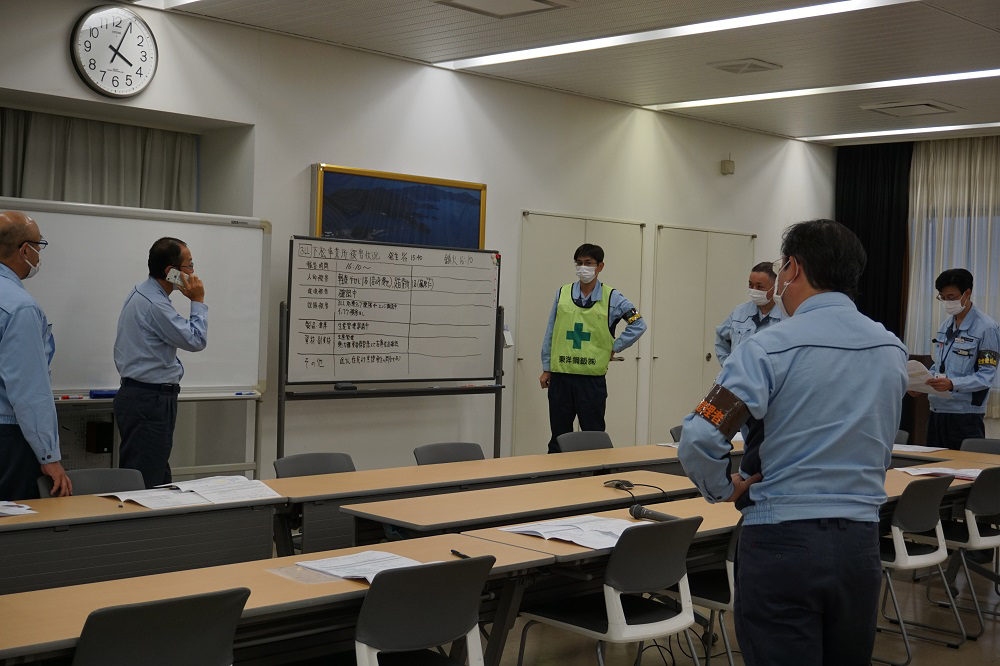

BCP Drill at Toyo Kohan

Toyo Kohan has established rules for risk and crisis management, and regularly conducts drills to test its business continuity plan (BCP). After a three year hiatus due to the COVID-19 pandemic, the company resumed the training in fiscal 2022. The drill simulated a scenario where a fire at the plant would force a suspension of production for 45 days.

The head office and Kudamatsu Plant worked together to verify the procedures for an emergency, using a web conference system to share information on damage to equipment and product inventories and delivery schedules for customers. Following the drill, they identified issues to address and reviewed the existing rules and manuals for deficiencies. We will continue with the training to enhance its capability of emergency response.

Formulating BCP and Conducting Drill to Prepare for Nankai Trough earthquake

Toyo Seikan has developed a BCP in anticipation of a potential megathrust earthquake in the Nankai Trough, which could cause simultaneous damage to multiple company plants. The BCP is designed to identify and prioritize tasks that would need to be addressed first in the event of such a disaster, thereby reducing the time required for recovery and ensuring the continuation of operations.

In March 2023, the company conducted a companywide drill based on the scenario of a Nankai Trough earthquake to test the effectiveness of its BCP. The drill involved setting up a virtual emergency headquarters,which communicated with all offices and plants via a web conference system and an online chat tool. Following instructions from the headquarters, each office and plant reported on their initial responses and the extent of damage to their facilities immediately after the simulated earthquake.

Training on Quality Emergency Response

At the Group, we have established guidelines to ensure a swift and organized response to quality-related emergencies, such as the distribution of products with significant defects or violations of quality compliance. To test the effectiveness of these guidelines, we conducted a simulated training exercise in collaboration with Toyo Seikan Group Holdings and selected operating companies.

The training was attended by relevant officers and department heads from both companies. They focused on checking the communication system during the initial response, the matters to be investigated, and the responsible departments, reviewing the entire processfrom the activation of the crisis response to the decision to disclose the issue. Any areas identified for improvement during the training were incorporated into the guidelines and shared across the Group.

Implementation of Information Security Education

As part of our risk management, The Group has beenimplementing education on information security sincefiscal 2022.

To protect the group companies from increasing cyberattacks, each member must raise their awareness of information security. We have provided all employees who have an email address with basic e-learning courses for information security management and simulation training for targeted e-mail attacks. With these programs,we are aiming to improve information security literacy in the workplace, such as increasing awareness in daily operations, to be more protected against cyberattacks.

In October 2022, during our month-long compliance promotion campaign, we invited a lecturer from TIS Inc., an IT service provider, to hold a training seminar for top management on information security compliance. The lecturer discussed the theme by referring to examples of compliance issues that actually happened, which helped the participants deepen their understanding.

We will continue to promote the importance of information security and carry out ongoing education.

Workshops on the Hazards of Chemical Substance at TOMATEC

At TOMATEC, we conducted workshops titled "Hazards of Chemical Substances Handled at TOMATEC", connecting the head office, Osaka plant, and other operational bases online. Additionally, under the auspices of the Health and Safety Committee at the company’s Kyushu Plant, we held workshops on the raw materials used in the pigment products, which were attended by many participants, including those in charge of manufacturing. In June 2022, during its “Hazardous Materials Safety Week”, we carried out internal patrols with a focus on verifying the management status of hazardous and toxic substances.