Steel Plate Related Business

Our steel plate related operations have been conducted mainly by our group company Toyo Kohan, adding value to steel with its proprietary technologies in rolling, surface treatment and lamination, which have been developed and refined since its foundation. This segment primarily manufactures and sells steel plate materials used for metal cans and other products that support various aspects of our daily living, including electrical and electronic components, automotive and industrial machinery parts, construction materials and consumer electronics.

Group companies of Steel plate related business

-

Toyo Kohan Co.,Ltd.

Manufactures and sells tin plates, thin plates, and various surface-treated steel sheets and various functional materials

-

KOHAN SHOJI CO.,LTD.

Sells steel sheets and their processed products

-

TOYO PAX CO.,LTD.

Manufactures and sells packing materials and packing work

-

KYODO KAIUN CO.,LTD.

Marine transport and harbor transport services, custom agent services

-

TOYO PARTNER CO.,LTD.

Services related to employee welfare facilities and others

-

Tokan Trading Corporation

Sells packaging materials, petrochemical products and food machinery, equipment & parts

-

TOYO KOHAN SHANGHAI CO.,LTD.

Sells steel sheet related products, hard materials and automatic binders and provides related services

-

TOSYALI TOYO CELIK ANONIM SIRKETI*

Production and sales of cold rolled steel sheet and surface treated steel sheet

* Affiliate accounted for under the equity method

Results

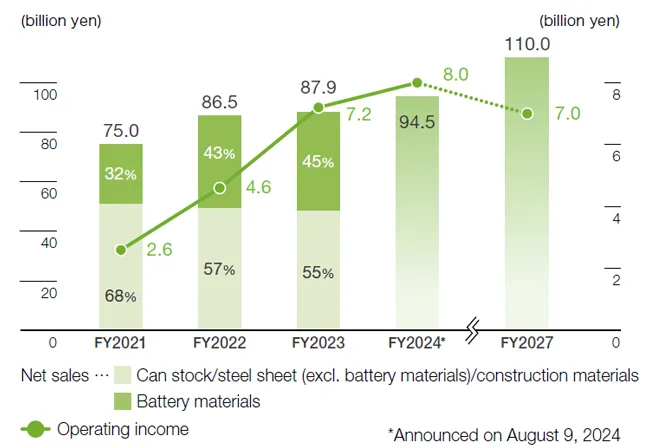

The steel plate related business recorded 87,942 million yen in net sales and 7,271 million yen in operating income, up 1.7% and 56.2% year on year,respectively.

SWOT Analysis

Competitive advantages

- Track record of developing highly specialized and proprietary technologies of processing, rolling, and surface treatment and applying them to various products and sectors with ingenuity and creativity

Issues

- Sustaining and expanding existing businesses

- Expanding the business domain and cultivating new fields

- Contributing to resolving the climate change problem

- Nurturing an organizational culture that supports talent that takes on challenges

Risks

- Higher quality requirements

- Difficulties procuring resources, increased costs

- Falling demand in the domestic market due to a falling birthrate and aging society

- Economic recession and intensification of market competition (market share falls as competitors increase production capacity, etc.)

Opportunities

- Productivity improvements from advancements in AI and progress in digitalization

- Higher demand for products that are environmentally sound and resource-saving including EVs and hybrids

- Higher revenue from products for overseas markets due to the cheaper yen

Strategy for continuous growth

- Invest management resources toward growth fields and bolstering competitiveness

- Cultivate new business domains and fields and environmental sustainability

- Build a supply network for battery components and materials (nickel-plated steel sheets) for growth EV vehicles and hybrids

- Ensure and raise profitability through a sustained shift to high-value-added products including nickel-plated steel sheets

- Implement cost pass-throughs to counter the increase in raw material and energy costs

- Conduct R&D and market trials for next-generation battery components and high-speed communication board materials

Progress and review of FY2023 in measures for continuous growth

- Investing in equipment and facilities related to automotive rechargeable battery materials

- New development projects (investment: about 12.5 billion yen; start of operations: Nov. 2023)

- Expanded development projects (investment: about 3.0 billion yen; start of operations: Jan. 2024)

1. Continuous growth in existing business domains

- Cost pass-throughs to counter increase in raw material costs and other cost increases

- Raise profitability through improved yields and productivity

2. Exploring, commercializing, and monetizing new growth opportunities

- Advancing human capital management

- Responding to climate change through introduction of solar power generation (offsite PPA, etc.)

- Leveraging IT (ERP, RPA, AI) to improve productivity

- Response measures for the aging Kudamatsu Plant (new and expanded manufacturing facilities)

3. Enhancing management foundation to support growth

- Invest in automotive rechargeable battery materials (new and expanded manufacturing facilities)

Strategy and key measures in FY2024

- Further examination of capital investment in the high-growth area of automotive rechargeable battery materials

- Solid construction of a supply network and its promotion