Achieving a Society Coexisting with Nature

Targets for 2030 and Progress in FY2023

「The table below shows the progress we made in fiscal 2023 based on the Eco Action Plan 2030.

Evaluation:★★★Achieved ★★Nearly achieved ★More effort needed

- The table can be scrolled left or right.

| FY2030 targets (Eco Action Plan 2030) | FY2023 results (main initiatives) | Evaluation |

|---|---|---|

|

Society coexisting with nature |

||

|

|

1 ★★★ |

|

|

2 ★★★ |

Addressing Water Resources

Basic Approach to Water Resources

With the improvement of living standards due to population growth and economic development, the global demand for water is expected to further increase, leading to an expansion of areas experiencing water scarcity. Additionally, the risk of disasters due to worsening extreme weather events is also increasing in various regions. Water is not only indispensable to the Group’s business activities but is also recognized as a cherished resource in regions where Group factories are sited. Consequently, at bases with a high reliance on water resources, we are reinforcing our actions toward greater efficiency of water use. Water risk is high in watersheds where production bases are located. Accordingly, we will carry out initiatives to reduce risk at facilities with large business impact and promote sustainable use of water resources.

Targets

The Group is carrying out initiatives to promote effective use of water and water conservation by accurately grasping the necessary water use from the production viewpoint and reducing excess water use. In the Eco Action Plan 2030 (“EAP 2030”) mid-term environmental benchmark, we have set forth the target of a “Water consumption for operations per unit of sales improved 1% from the previous fiscal year.” Results from 2023 show that we achieved the targeted 6% reduction. Continuing these efforts into 2024, our initiatives address efficient use of water and risk reduction efforts.

Water Risk Assessment

Among the physical risks in TCFD, we recognize that the risks of water shortages and flood damage have a large impact on Company business. Therefore, in the watersheds where our production sites are located, we conduct risk assessments to identify water resource risks in advance and take appropriate measures. We will continue to have risk assessments in which we periodically understand fluctuations in risk and bolster our initiatives toward reducing risks.

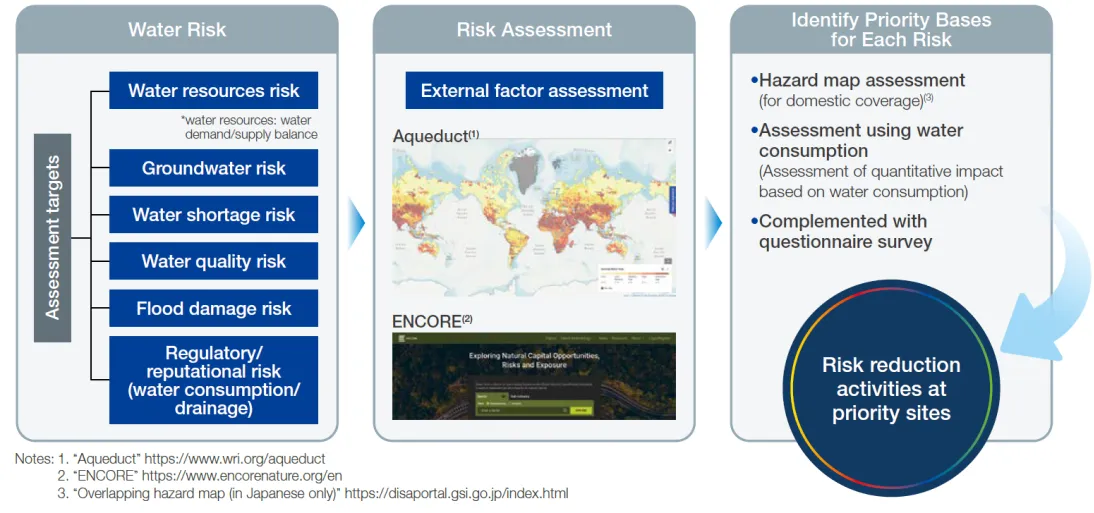

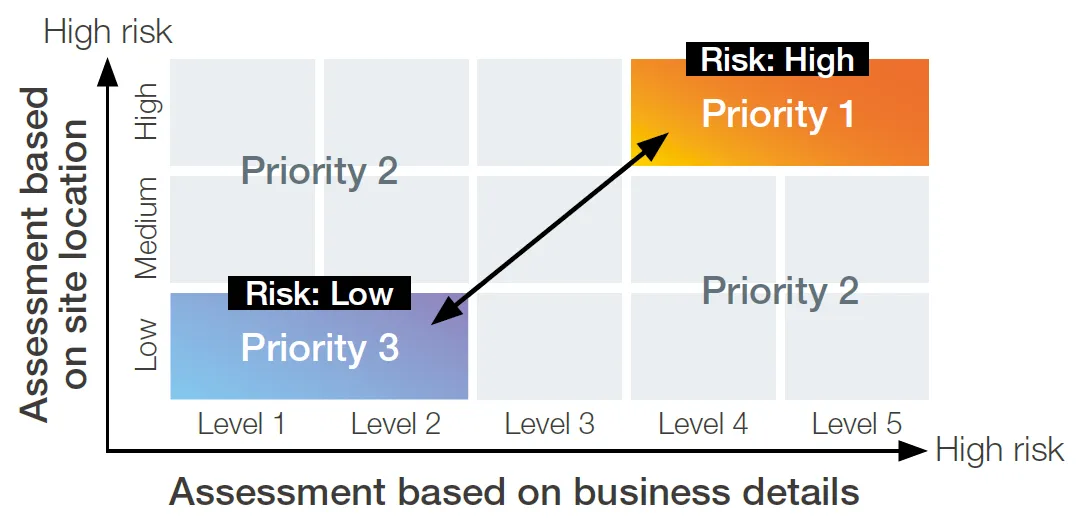

Covering the 93 main Group production bases, both in Japan and overseas, we place risks into six categories (water resources, groundwater, water shortages, water quality, flood damage, regulatory and reputational) and then conduct a risk assessment. When conducting the assessment, we first assessed risks from base sites using Aqueduct(1) and then assessed the dependence and impact on business activities using ENCORE(2). We consolidated these various risk assessments and then classified the external factor assessment into three levels (Priority 1 to Priority 3). Targeting bases with high Priority 1 risk as found in an external factor assessment that combined water consumption at bases, hazard maps, and questionnaire survey results, we identified the high-risk priority bases.

Water Risk Assessment: Activity Flow

* The table can be scrolled left or right.

About Risk Assessments

Assessment Results

The bases extracted to priority bases are the seven bases in the table below. These bases, which are listed in EAP 2030, are having measures implemented in circulatory use and effective application of water, with a target set of 1% improvement in water consumption per net sales. We also strive to reduce the risks from flood damage, through the installation of watertight dikes and waterstops and by implementing business continuity planning (BCP) and related measures. Through its intent to minimize water risks centered on high-risk sites identified using this assessment, the Toyo Seikan Group contributes to solutions to water issues in each region.

The Base that has been Extracted as Priority 1

| Water resources risk | 2 overseas bases |

|---|---|

| Regulatory and reputational risk | 1 overseas base |

| Flood damage risk | 3 bases in Japan / 4 overseas bases |

Activities of Toyo Seikan Group

Addressing Marine Plastic Pollution

Engagement through Clean Ocean Material Alliance

Marine plastic pollution is a pressing global issue. To tackle this problem, it is essential for both public and private sectors to collaborate in promoting more sustainable use of plastic products, as well as in the development and introduction of alternative materials. In light of such circumstances, in January 2019, the Clean Ocean Material Alliance (CLOMA) was established with a wide range of business operators involved in the supply chain. As of April 2023, it consists of 486 companies and organizations from various industries. Toyo Seikan Group Holdings has been involved since the preparatory stage as a managing partner and has been actively participating as a key member of the Dissemination & Promotion Working Group, fostering information sharing and collaboration across different industries.

Furthermore, the Group has been actively involved in all five working groups of CLOMA, which were established to implement the Action Plan launched in 2020. The Group has been contributing to the planning of demonstration tests among other tasks. Through these activities, we will continue to contribute to the solution of marine plastic pollution.

Strong Commitment to Plastic Pellet Loss Prevention

Plastic pellets with a size of several millimeters, which are used to make plastic products, could become marine plastic litter if they escape from the plant site. We have been taking measures to prevent the particles dropped on the ground from flowing out the site, including placing metal net on the storm drain. In 2019, to further ensure appropriate pellet management aimed at zero pellet loss, we formulated the Group’s Guidelines for Preventing Plastic Pellet Loss. The relevant group companies have started implementing the guidelines under their respective environment management systems by identifying potential leakage points, taking preventive measures, and conducting daily management processes and auditing.

Pellet-collecting screen set on a rainwater catch basin

Facility Risk Management

We strive to prevent accidents that could negatively impact the quality of public water bodies (such as rivers and oceans) and groundwater. These accidents could be caused by incidents such as oil leaks from plants or discharge of abnormal wastewater due to issues with wastewater treatment.

To achieve this, we adhere to the environmental management systems of each company within our group. In particular, we have established “Toyo Seikan Group Facility Environmental Risk Management Guidelines” in 2021, which we use to regularly manage the degradation of damage of equipment, pipes, tanks, and valves that have a high risk of causing environmental accidents. We will continue to make improvements by implementing the PDCA (Plan-Do-Check-Act) cycle based on each company’s environmental management system.

Activities of Group Companies

Acitivities Related to Water Resources

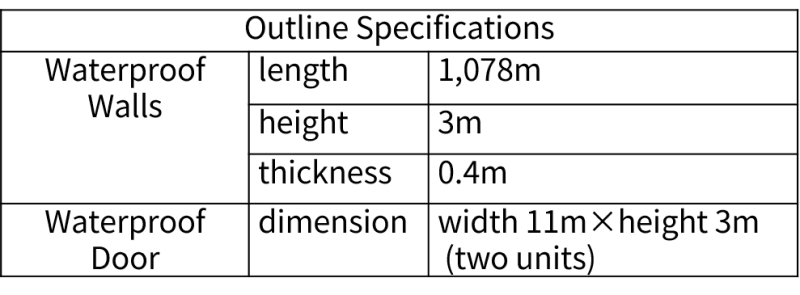

Installation of Waterproof Walls and Doors at Toyo Seikan Hiroshima Factory

In order to protect the lives of employees and the factory in the event of similar natural disasters in the future, in June 2020, we installed 3-meter-high waterproof walls and doors at the boundary of the premises, following the flooding damage caused by the heavy rainfall in Western Japan in 2018. These measures aim to prevent flooding within the premises and also serve as a refuge for nearby residents.

Waterproof Walls

Waterproof Door Wall

Evacuation Staircase for Nearby Residents

The Rainwater Collection System at Toyo Glass Chiba Factory

At Toyo Glass Chiba Factory, we capture rainwater that falls on the roofs of our packaging area, supply it to a storage tank, and utilize the rainwater effectively. We collect approximately 2,606 cubic meters of rainwater annually.

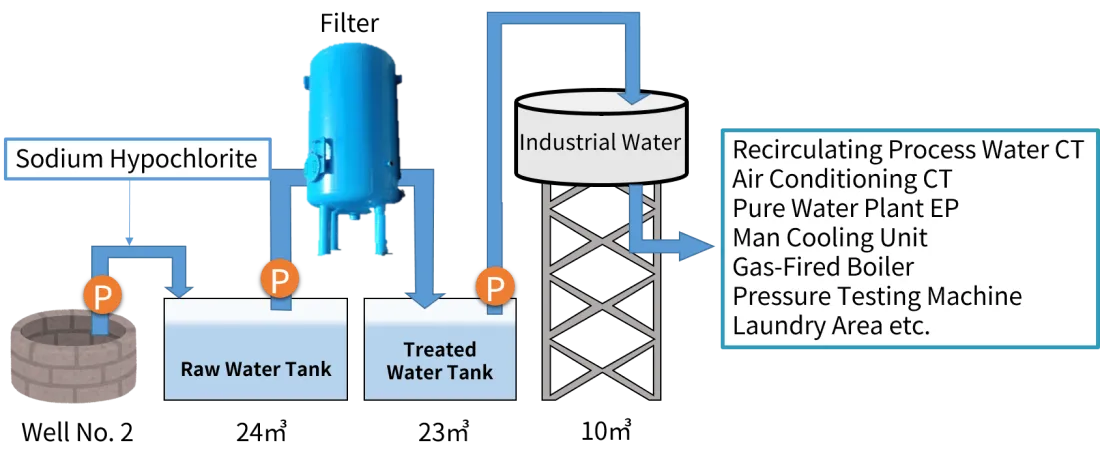

Water Flow Diagram in a Facility

Installation of Rainwater Collection Piping

Developing environmental DNA (eDNA) chip to identify alien fishes in dams

Through a joint research with Yamaguchi University and Nippon Koei, Toyo Kohan has found that its gene analysis system with DNA chips developed for medical use can be applied in environmental fields. To monitor alien fishes in dam reservoirs, researchers have generally dived into the reservoirs and caught fishes with a net, which requires costs, time and efforts. With eDNA chips provided by Toyo Kohan, researchers can easily identify what kind of alien species are in dam reservoirs simply by analyzing a liter of water collected from the reservoirs. Alien species are organisms that are non-native to a particular environment and can significantly harm the existing ecosystem as a result of their invasions.

The eDNA chip can detect even a very small amount of environmental DNA (eDNA) shed by alien fishes into the water of dam reservoirs through their feces and scales. Findings of the joint research with the eDNA chip were published in Landscape and Ecological Engineering, an international academic journal, in June 2022.

While expanding applications of its DNA chips for medical purposes, Toyo Kohan will also promote the use of the chips for environmental conservation, including in rivers and dam reservoirs. This contributes to solving environmental issues and achieving the SDGs.

Joining Japan Blue Carbon Network

Interest in blue carbon has increased in recent years from the perspectives of Sustainable Development Goals (SDGs) of "climate action” (goal 13) and "life below water" (goal 14). As well as plants on land, seagrasses and seaweeds absorb CO2 when they grow. The carbon stored in coastal and marine ecosystems is known as blue carbon.

Toyo Glass, possessing the technology of sustained-release water-soluble glass*, has been contributing to the promotion of blue carbon ecosystems, including the restoration of seaweed beds, by utilizing the characteristic of the active ingredients in the glass slowly dissolving into water.

Toyo Seikan Group Holdings has recently become a supporting member of the Japan Blue Carbon Network, a non-profit organization. We have been actively involved in sharing information about domestic and international initiatives related to blue carbon and seaweed bed restoration, as well as providing support for these initiatives. Additionally, we have been disseminating information about climate change and marine ecosystems. In October 2022, we participated in a seminar and an on-site workshop held by the Japan Blue Carbon Network in Atami City, Shizuoka. In February 2023, we also discussed new approaches to blue carbon issues with other members. We will continue to protect marine biodiversity and combat climate change, cooperating with diverse research institutions, organizations and companies engaged in blue carbon activities.

Activities for FY2023

Activities in Forest Management

At Toyo Kohan Co., Ltd. Kudamatsu Plant, we are committed to forest conservation activities, taking into consideration the prevention of global warming and the importance of water. In October 2023, we participated in the 27th "Town, Forest, and Water Exchange Meeting" organized by the Yamaguchi Prefecture Shunan Agriculture, Forestry and Fisheries Office, which was held in "Fureai no Mori" located upstream of the Sugano Dam in Shunan City, Yamaguchi Prefecture. Approximately 200 volunteers from Yamaguchi Prefecture and the Shunan region, including companies, participated in this event. During the exchange meeting, we used tools such as saws to carry out tasks such as cutting underbrush and removing dead trees, contributing to the maintenance of the forest.

Participation in "Hokkaido Corporate Forest Creation"

Nippon Tokan Package Co., Ltd. is participating in the "Hokkaido Corporate Forest Creation" initiative promoted by the Hokkaido Government. With the cooperation of the Numata Town Office in Hokkaido, we have leased approximately 0.5 hectares of forest in Numata Town and named it "DANDAN no Mori." We started forest maintenance activities in September 2023. Numata Town is known as one of the heavy snowfall areas in Hokkaido, and the duration of the activity period in which employees can participate is about six months throughout the year. However, starting from the 2024 fiscal year, we plan to recruit participants from all locations and provide opportunities to get closer to nature through forest maintenance activities.

We will cut down the kuma bamboo grass so that sunlight reaches the ground.

Sometimes we maintain it together with horses and sheep.