Technology Development

Based on the know-how in materials development, molding, and engineering techniques cultivated to date by the Company, we are actively engaged in the development of innovative technology and the environment. Through technology and development, we continue to offer eco-friendly products, which enables us to respond to customer expectations and to contribute to the sustainable development of society as a whole.

Message from the Chief Technology Officer

Takuji Nakamura

President and Representative Director

Chairman of Group Risk and Compliance Committee

Chief Technology Officer

Aligning technology, IP, and management strategy, and offering solutions for every single social issue to show the way to sustainable growth.

Our Strengths in Technology Development and Its Challenges

The strengths of the Toyo Seikan Group lie in the technology we call monozukuri (Japanese concept of manufacturing, or the art, science and craft of making things), centered on packaging and containers and cultivated over many years. In response to the needs of our customers, we continue to develop forms and features well-suited to a diversity of applications̶beverages, foods, and daily goods̶using various materials including metal, plastic, paper, and glass. Even during these times of intense cost competition, we have not downsized our production bases, but instead have upscaled to high-quality, high-value-added development.In addition, we at the Group are not only interested in technology for packaging itself. Our interests extend to basic research into materials and evaluation of physical contents as well as the design of production equipment, among other activities. We also own various elemental technologies and have the talent to turn them into concrete applications. This is not just about technology related to products and equipment that are visible. It is also about the importance of paying attention to the value of intangible assets, which basically consist of expertise and know-how, and putting such assets to active use. This, I feel, is the challenge for the Group.

As the Japanese economy grew, demand for packaging and containers increased and the Group also continued to grow; meanwhile, the environment surrounding the business has undergone great changes. Given sustainability initiatives and solutions to environmental issues demanded throughout the world today, it has not been enough just to develop technology aimed at the stability of our advantages, i. e., large volume manufacturing and quality. In particular, the efficient use of resources as expressed in the slogan “reduce, reuse, recycle” can at times run counter to the part of the Group’s business model concerning producing single-use containers in large volume. For example, even if new materials are developed that reduce the volume of plastic resins in use, and recycling is possible, and even if a recycling process is established for the materials, it has little consequence unless a collection process is also established. In other words, technology development must consider the entire recycling process starting with product design.

We therefore must carry out technology development and business development that leverages the know-how and intangible assets accumulated from the past in a way that extends beyond the existing technology and business of packaging to develop new business while responding to the diverse issues and needs of society.

Aim for Both Forms of Sustainability: Contributing to the Environment and Corporate Growth

Many social challenges are presenting themselves around the world today. For every social issue in the packaging field, we will offer support in the form of providing the organizational structure and systems necessary to solve the issue. In doing so, we will make full use of our technologies cultivated up to now and exercise an IP strategy that leverages our intangible assets. By aligning our technology strategy, our IP strategy, and our management strategy, we will pursue our hope and vision of serving as a corporate Group that continues to drive innovation, as we have in the past. What I see here is a quick way to realize a sustainable future, not just for the Toyo Seikan Group but for the environment itself.Technology Development Framework

Our technology development activities are conducted with cooperation between the Corporate R&D, the basic research and development unit of Toyo Seikan Group Holdings, and technical development departments of group companies.

Activities of Group Companies

Addressing Challenges Presented by the Shift to Lighter Weight Aluminum Beverage Cans and Reducing Environmental Impact

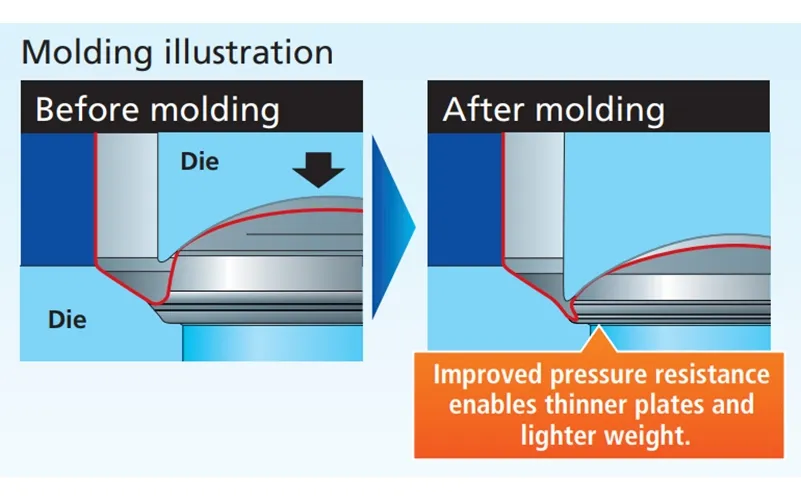

Toyo Seikan Co., Ltd. reformed and enhanced the bottom of its aluminum beverage cans and introduced Compression Bottom Reform (CBR) technology, which improves the pressure resistance and strength of the can bottom to reduce weight. By using this technology, we were able to significantly reduce the weight of aluminum beverage cans, which is expected to further lower greenhouse gas (GHG) emissions.

Forming the Can Bottom Using CBR

GHG Emissions: Expecting 40,000t per Year in Reduced Emissions

CBR facilitated the achievement of weight reductions from 11.7g to 10.2g for a 350-ml can and 15.0g to 13.0g for a 500-ml can, for savings of 1.5g and 2.0g respectively. In GHG emissions per can, this allowed us to achieve a 9% reduction from current model cans for both 350-ml and 500-ml sizes. Additionally, the 190-ml can was reduced from 7.0g to 6.1g, achieving a weight reduction of 0.9g and an 8% reduction in GHG emissions per can. If aluminum beverage cans for which CBR can be applied are all made using CBR, estimated annual GHG emissions savings would be around 40,000t.*

- Estimate based on 2022 annual manufacturing results for aluminum beverage cans using current specifications at Toyo Seikan and GHG reduction volume per can using CBR.

For details, please see the following press release.

- [Press Release dated March 26, 2024] Toyo Seikan develops and begins mass production of the lightest aluminum can body in Japan, contributing to further reduce greenhouse gas emissions

- [Press Release dated August 29, 2024] Toyo Seikan’s world’s lightest aluminum can to be used by Coca-Cola for its Georgia coffee brand -Mass production started, achieving further reductions in GHG emissions-

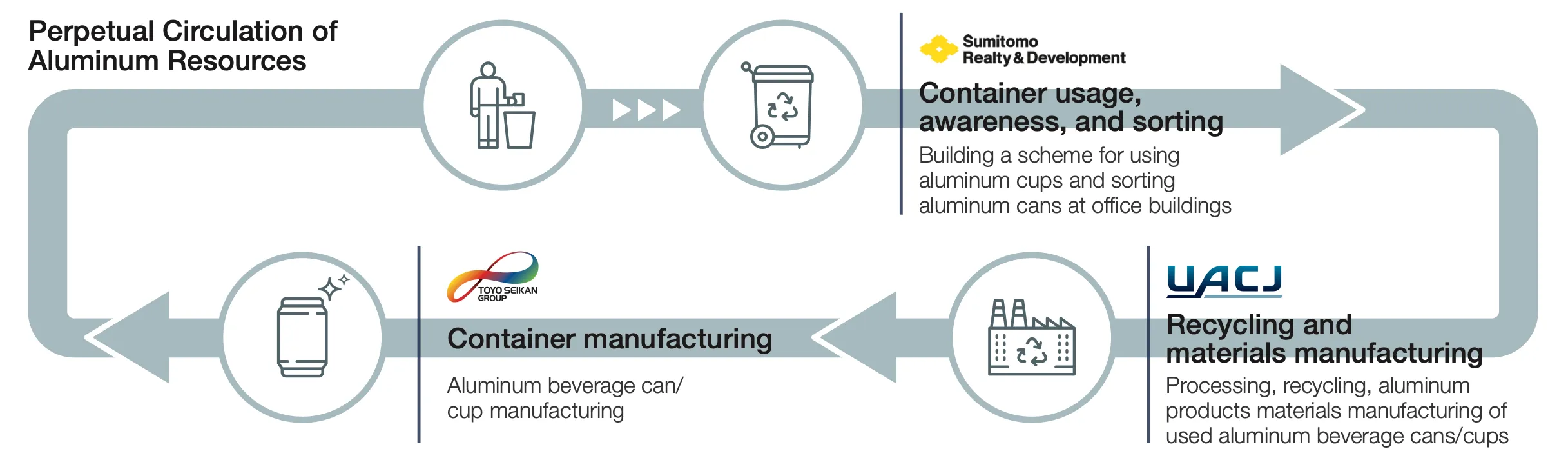

Toward Realization of a Circulatory Society Building a Supply Chain for Horizontal Recycling of Aluminum

In cooperation with Sumitomo Realty and Development Co., Ltd. and UACJ Corporation we have built a supply chain for what we call “horizontal recycling of aluminum.” This initiative has been applied to recycling used aluminum cans as reused aluminum cans and the Lumisus® aluminum cup. After conducting test applications in 2023, we started full-scale operations in April 2024.

Under this recycling scheme, aluminum cans discarded from Sumitomo Realty and Development office buildings go through a recycling process, after which they are delivered as recycled raw materials to a UACJ plant and processed into aluminum sheet products. Then, new aluminum cans and Lumisus® aluminum cups are manufactured by the Toyo Seikan Group using recycling. This horizontal recycling fosters a reduction in import dependence on new primary aluminum, helps to realize resource recirculation in Japan,and makes a large contribution to curtailing GHG emissions.

The table can be scrolled left or right.