Toward a Zero-Waste Society

Basic Perspective

Toyo Seikan Group's business involves processing raw materials, such as metals and petroleum, to manufacture packaging containers and steel plates. Therefore, effectively utilizing resources, including reducing input materials and minimizing waste generation through recycling, is a significant mission for the group. In particular, packaging container waste accounts for 63.6% of household waste by volume, according to the composition survey conducted by the Ministry of the Environment in 2023.

Under the "Eco Action Plan 2030," we have set a goal to reduce the use of finite resources by 30% and are actively working towards achieving a resource-circulating society. In addition to the ongoing efforts to lightweight containers, we are also actively promoting the use of recycled materials. Improving the usage rate of recycled materials in metal cans and increasing the use of recycled materials and plant-derived resins in plastic containers contribute not only to the goals of the "Eco Action Plan 2030" but also to solving societal issues. These activities are not only important for the effective utilization of resources but also contribute to energy reduction during material manufacturing, making them crucial in terms of addressing global warming. We are also working on creating mechanisms to promote product design and development suitable for sorting and facilitate the collection of used containers, contributing to the realization of a circular economy.

2030 Targets and FY2023 Results

Based on Eco Action Plan 2030, the progress on group-wide targets as of FY2023 is stated below.

Evaluation:★★★Target achieved ★★Slightly below target ★Initiative falls short of target

* The table can be scrolled left or right.

| FY2030 targets (Eco Action Plan 2030) | FY2023 results | Evaluation |

|---|---|---|

|

Zero-waste society |

||

|

|

★★ |

|

||

|

- Exhaustible resources: Natural resources that are not replenished by natural processes at a greater speed than used by humans, etc.

- Fossil resources: Petroleum, natural gas, etc.

Environmental Impact of Business Activities

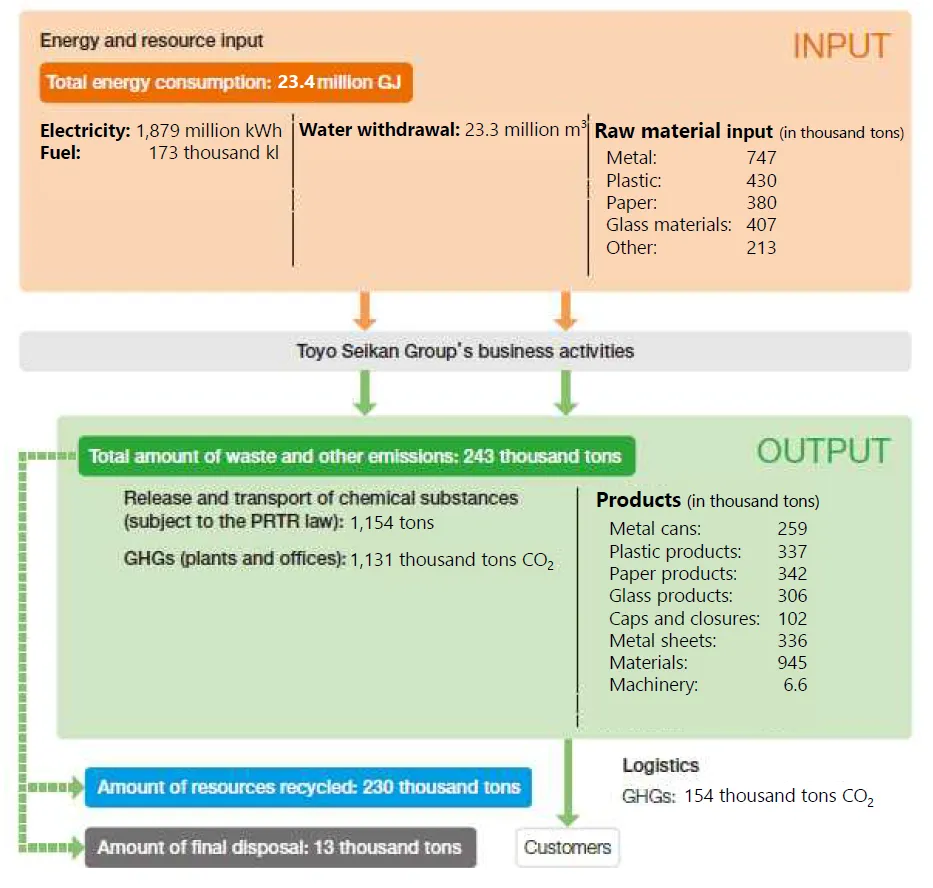

We strive to monitor the material balance of the entire group in an effort to reduce the environmental impact of our business activities.

Material flows of Toyo Seikan Group (FY2023)

- The table can be scrolled left or right.

Sustainable Packaging

Packaging play a crucial role in protecting and facilitating the transportation and storage of products. They also provide information to consumers and stimulate their purchasing desires. However, traditional packaging have largely been disposable, placing a significant burden on the environment. It is now important to reduce the environmental impact of packaging. Achieving sustainable packaging requires the use of renewable materials, promoting recycling, and lightweighting, among other measures. Additionally, it is essential for companies and consumers to collaborate in making environmentally conscious choices. To preserve the Earth's environment while sustaining economic activities, our group is committed to developing sustainable packaging.

Reduce: Activities to Lightweight Packaging

Tokyo Seikan Group has been working on lightweighting packaging to reduce the amount of materials used. By lightweighting packaging, we can reduce the use of depleted resources such as iron and aluminum, which are materials for metal cans, and petroleum, which is a material for PET bottles. Our group packaging to make efforts to effectively utilize limited resources while maintaining and improving the usability and quality of packaging to protect their contents.

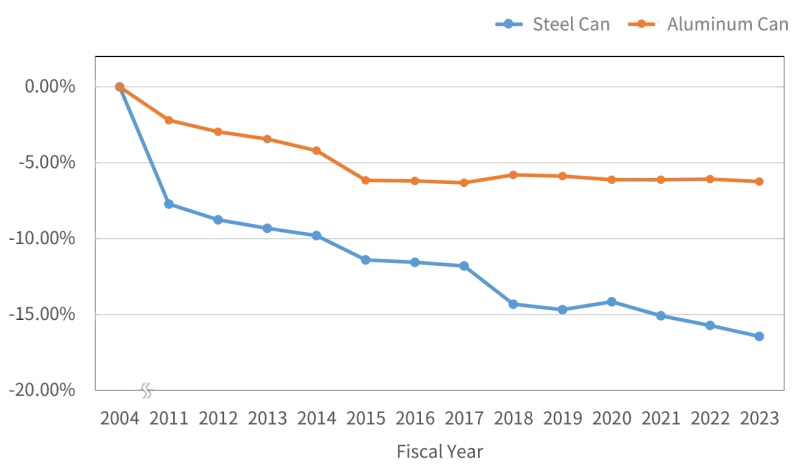

Beverage Steel Cans and Aluminum Cans

The weight of beverage steel cans and aluminum cans has been reduced by using thinner steel sheets and aluminum plates, and the weight reduction rate in the 2023 fiscal year is approximately -16% for steel cans compared to the 2004 fiscal year, and approximately -6% for aluminum cans.

The Weight Reduction Rate of Beverage Steel Cans and Aluminum Cans Over Time*

- * The weight average of all beverage cans manufactured by Toyo Seikan, and the trend of lightweight rate based on the weight average in 2004.

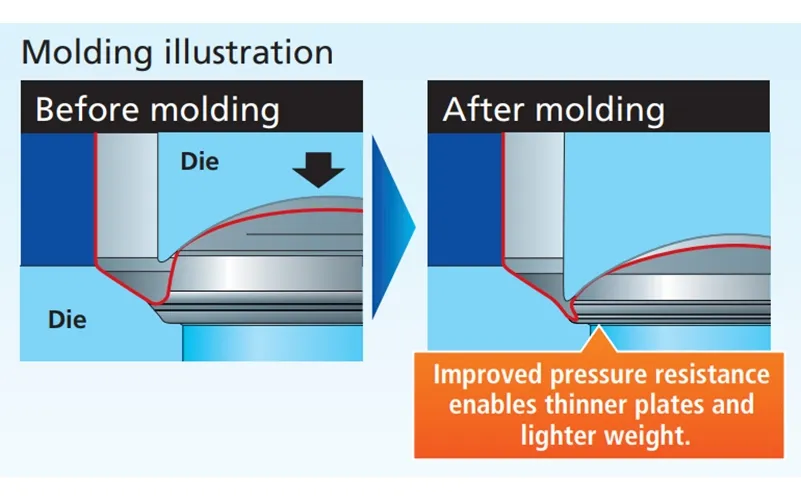

Lightweight Aluminum Cans Through Compression Bottom Reform (CBR) Technology

Toyo Seikan has successfully developed aluminum beverage cans using compression bottom reform (CBR) technology, which involves reinforcing and lightweighting the bottom of the cans. This technology has been applied to aTULC cans with a diameter of 202 (190ml) and Aluminum DI cans with a diameter of 211 (350ml and 500ml). This development has made it possible to reduce the weight compared to conventional aluminum beverage cans.

Please refer to the following press release for details on emission reduction amounts and more.

[Press Release - August 29, 2024] Toyo Seikan’s world’s lightest aluminum can to be used by Coca-Cola for its Georgia coffee brand -Mass production started, achieving further reductions in GHG emissions-

PET Bottle

PET bottles for beverages or condiments, for example, have been designed and manufactured with various innovations such as shape and molding conditions to reduce the amount of resin used.

Easy to Use and Easy to Dispose of Environmentally Friendly PET Bottles【Collaborative Development with KAGOME CO.,LTD.】

Coca-Cola🄬 500 ml 100% r-PET Lightweight Bottle【Collaborative Development with Coca‑Cola(Japan)Company, Limited】

Toyo Seikan has achieved a weight reduction from 23g to 21g (9%) by changing the shape of the preform, an intermediate product, and the petaloid shape at the bottom of the bottle. This lightweighting was done while ensuring the same performance and design as the conventional packaging.

Press Release - October 24, 2024:

Glass Bottle

Universal Design Bottle

Universal Design Bottle Product Page

Cap

Milk Cap for PET Bottles

Milk Cap for PET Bottles Product Page

Reuse: Activities for Packaging Reuse

By cleaning packaging thoroughly and reusing them multiple times, it is possible to reduce waste.

Standardized Reusable Bottle "R-mark Bottle"

Plastic Main Body Packaging and Refillable Film Pouch

Reusable Bottle

Recycling: Activities for Packaging Recycle

By reusing used packaging as raw materials, we can contribute to resource conservation. Toyo Seikan Group actively participates in the activities of recycling organizations associated with our packaging business, including their operation. We also promote recycling through the design and development of packaging that are easy to separate, as well as through activities such as the Museum of Package Culture and exhibition participation.

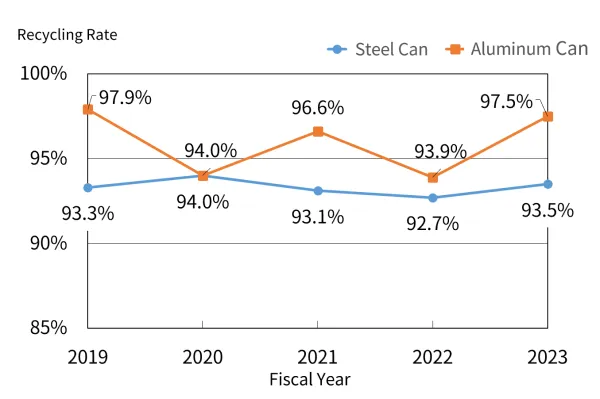

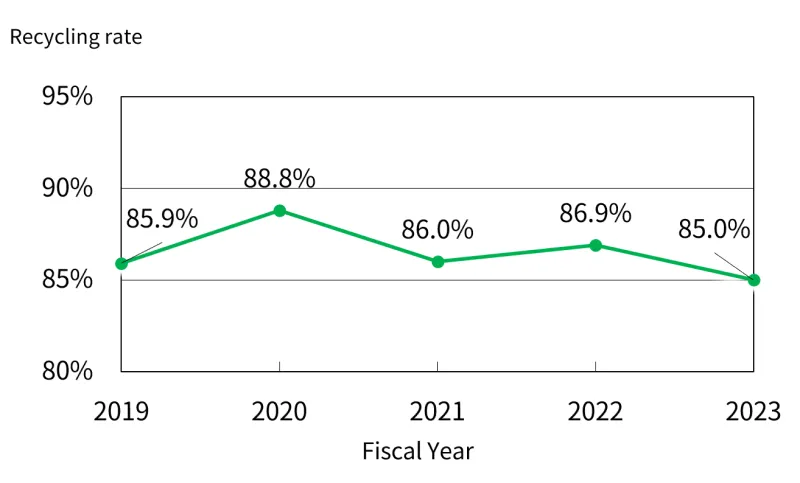

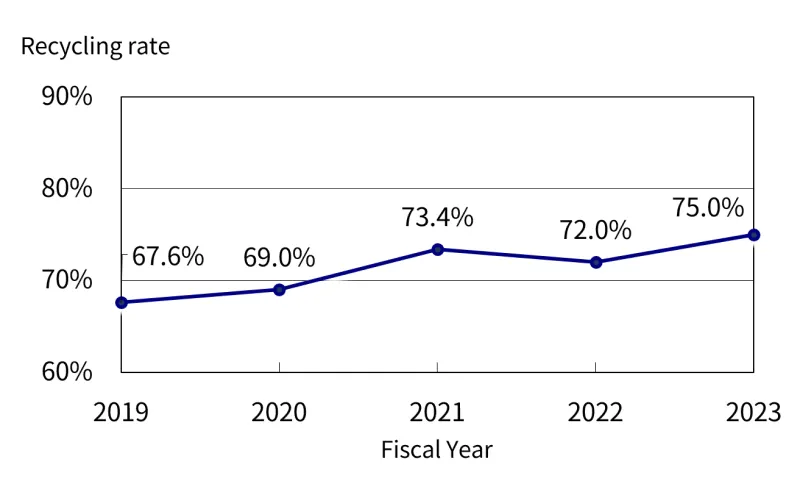

Trends in recycling rates by product category in Japan [Data reproduced from various organizations' publications]

Steel Cans*1 / Aluminum Cans*2

PET Bottle*3

Glass Bottle*4

- Japan Steel Can Recycling Association: The numerical target of the voluntary action plan 2025, which started from the fiscal year 2021 and aims to achieve by the fiscal year 2025, is to "maintain a recycling rate of 93% or higher."

- Japan Aluminium Can Recycling Association: The goal of the "Voluntary Action Plan 2025" is to maintain a recycling rate of 92.0% or higher.

- The Council for PET Bottle Recycling: The "Voluntary Action Plan 2025 for Promoting 3R" aims to maintain a recycling rate of 85% or higher.

- Glass Bottle 3R Promotion Association: The target for the fiscal year 2025 is to maintain a recycling rate of 70% or higher.

Low Environmental Impact Can Lids made from Recycled Materials "EcoEnd™"

Please refer to the following press release for details.

[Press Release - December 4, 2023] Development of Next-Generation Eco-Friendly Can Lid 'EcoEnd™' with Major Revisions to Materials and Manufacturing Methods - Joint efforts by Toyo Seikan and UACJ reduce greenhouse gas emissions by 40%

[Press Release - July 9, 2024] Completion of the mass production system for "EcoEnd™," the Next-Generation Beverage Can Lid, Which Achieves a 40% Reduction in Greenhouse Gas Emissions - A Collaborative Effort by UACJ and Toyo Seikan -

Towards the Realization of Horizontal Recycling of PET Bottle Caps

Activities towards Obtaining Mass Balance Certification

- The method of allocating the characteristics of certain materials to a portion of the produced products based on the input quantity of the materials with those characteristics, when those materials are mixed with other materials during the processing and distribution stages from raw materials to finished products.

- ISCC is an international certification system that focuses on sustainability and carbon aspects. Within ISCC, ISCC PLUS is a system that ensures the management and traceability of biomass-based, recycled, and other sustainably sourced materials and products throughout the supply chain, including those sold worldwide.

[Declaration regarding ISCC PLUS requirements]

Toyo Seikan Group commits and declares to comply with the latest provisions of ISCC and adhere to the requirements of ISCC PLUS. We also promise not to engage in double counting regarding environmental contributions.

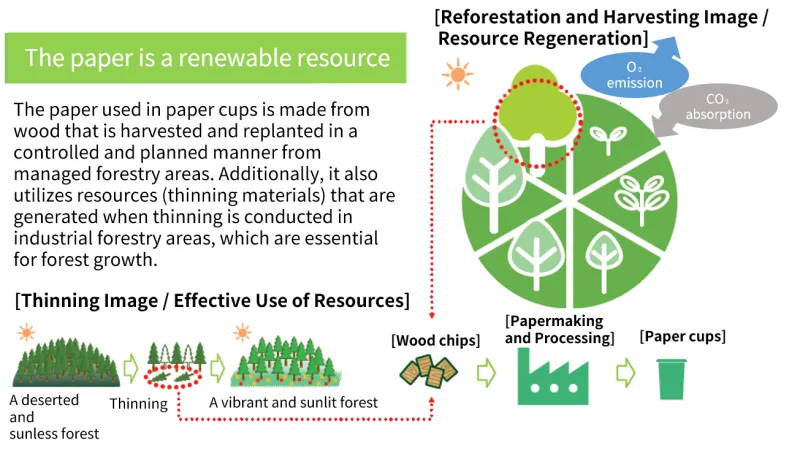

The Use of Sustainable Paper Resources

Tokan Kogyo manufactures and sells paper cups using thinned wood as raw material. Thinning refers to the selective cutting of some trees to promote the growth of the remaining trees and maintain the health of the forest. The timber obtained from thinning is referred to as thinned wood. By using thinned wood, Tokan Kogyo contributes to forest conservation and achieves sustainable resource utilization.

Participation in the Initiative

About R Plus Japan Co., Ltd.

Compliance with The Containers and Packaging Recycling Law

Toyo Seikan Group pays an annual recycling commission fee to The Japan Containers and Packaging Recycling Association, as specified by The Containers and Packaging Recycling Law, in order to contribute to the realization of a circular society. For more details about this system, please refer to the website of The Japan Containers and Packaging Recycling Association.

The Japan Containers and Packaging Recycling Association WebsiteActivities of the Group or Business Company

Activities for FY2024

"Zero Waste Fest 2024" Opening Event Held on May 3rd (Waste Day)

In collaboration with "Takizawa Garbage Club," led by comedian and garbage collector Machine Guns Takizawa, Toyo Seikan Group held a public opening event at our company (Osaki Forest Building) on May 3, 2024 (Fri, holiday), which marked the first day of "Zero Waste Fest 2024."

The theme for this year was "Waste x Art," aiming not only to promote SDGs but also to provide an enjoyable event for people of all ages through art created from garbage. On the day of the event, various activities related to garbage, such as talk events and workshops, were conducted to make SDGs more relatable. Many people, including local residents and those interested in environmental issues, attended the event.

Activities for FY2023

Building a Supply Chain for "Horizontal Recycling" of Aluminum Cans towards Achieving a Circular Economy

Toyo Seikan Group Holdings, Sumitomo Realty & Development Co., Ltd. ("Sumitomo Realty"), and UACJ Corporation ("UACJ") have jointly established a supply chain for "horizontal recycling" of used aluminum cans, where they are recycled into raw materials and utilized again for aluminum can manufacturing. After conducting test operations in 2023, the supply chain officially commenced operations in April 2024, starting from office buildings owned by Sumitomo Realty in Tokyo.

In this newly established supply chain, aluminum cans discarded from Sumitomo Realty's office buildings undergo the recycling process and are delivered as recycled materials to UACJ's factories, where they are processed into aluminum sheet products. Ultimately, these aluminum sheet products are reused within the Toyo Seikan Group to produce aluminum cans and beverage aluminum cups called "Lumisus®."

Furthermore, to raise awareness and promote recycling consciousness among office users, Sumitomo Realty plans to introduce and utilize "Lumisus®" as outdoor beverage cups, starting with events such as the Sakura Festival held in their offices. The cups will follow a similar scheme to aluminum cans for horizontal recycling.

Aluminum primary metal is predominantly imported, making it susceptible to international influences. Achieving horizontal recycling promotes the substitution of aluminum primary metal with recycled metal, contributing to domestic resource circulation and reducing greenhouse gas emissions.

Opening Event of “Zero Waste Fest 2023”

The Group partnered with the Takizawa Garbage Club, organized by garbage collector and comedian Shuichi Takizawa (a member of comedy duo Machine Guns) on a waste reduction initiative to raise public awareness.

The Takizawa's club held the Zero Waste Fest 2023, a month-long campaign from May 3, 2023 (“Garbage Day”) to May 30, 2023 (“Zero Garbage Day”), in various locations across Japan. On May 3, the first day, we co-hosted the opening event of the Fest at the Group's head office building in Osaki, Tokyo, under the theme of ""Embrace the SDGs not out of obligation, but out of desire."" The event was designed to create an opportunity for participants to find fun in recycling activities through various small programs that are linked to everyday life.

Admission was granted in exchange for recyclable waste containers brought by the visitors. At the venue, we arranged interactive exhibits with products developed by the Group, including a prefabricated cardboard tent that is recyclable; Captain Box, game-like equipment to collect used PET bottle caps; Re-CUP WASHER, a cup washer to promote paper cup recycling; and Loopiece, craft materials “upcycled” from used glass bottles. The stage featured a talk session with Mr. Takizawa, other comedians and guest speaker Ken Noguchi, an alpinist and environmental activist, as along with a picture-story show and music performance themed around waste issues and the SDGs.

The event was attended by around 300 individuals from the neighborhood and other areas.

Initiatives towards the Deployment of the Cup Cleaning Machine "Re-CUP WASHER"

Tokan Kogyo is actively working on the implementation of the "CUP TO CUP Recycling System" using the cup cleaning machine "Re-CUP WASHER" to recycle paper cups and convert them into recycled cups. In the fiscal year 2023, they carried out the following initiatives and will continue to expand the deployment of Re-CUP WASHER to contribute to the realization of a circular economy:

- Demonstration of paper cup recycling at the G7 Hiroshima Summit International Media Center (IMC)

- Started the sale, rental, and leasing of the Re-CUP WASHER machine from January 2024.

- Participated in awareness-raising activities by collecting used cups and promoting recycling at the "Miyajima Night Market."

Reducing Landfill Waste by Reusing Packaging Materials

Stolle Europe Ltd., based in the UK, has successfully reduced landfill waste by approximately 25% through the reuse of packaging materials such as still usable wooden crates during shipment.

Furthermore, Stolle Europe Ltd. maintains business relationships exclusively with suppliers who have obtained carbon-neutral certification or are actively engaged in sustainable practices. Waste generated from Stolle Europe Ltd.'s conveyor department is strictly managed in accordance with the Waste Regulations 2011 and is recycled through local registered waste management companies.

Promoting Reuse of Electronic Waste

Stolle Machinery Company, LLC, based in the United States, actively avoids landfill disposal of electronic waste by partnering with recycling companies for proper collection. Once collected by these recycling companies, the electronic waste undergoes careful processing to extract valuable rare metals and transform them into reusable silicon.

It is estimated that only 17.9% of electronic waste worldwide is currently being recycled. In line with its commitment to sustainability, Stolle Machinery Company, LLC will continue to drive initiatives aimed at increasing the recycling rate and improving overall sustainability.