By significantly increasing the use of recycled materials, which have a GHG emission of approximately 3% compared to primary aluminum, we have achieved a substantial reduction in GHG emissions during the production of raw materials. Compared to current beverage can lids, EcoEnd reduces GHG emissions by approximately 13,000 tons per billion lids.*2 If all beverage can lids sold by Toyo Seikan in Japan are replaced with EcoEnd, an estimated annual reduction of approximately 140,000 tons can be achieved.*3

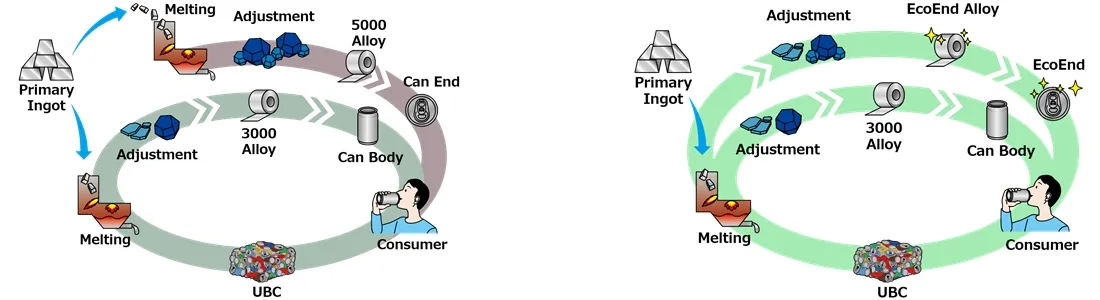

Because the strength and other characteristics required for the lid and the body of the can are different, a certain amount of primary aluminum needs to be used for the lid, and the composition needs to be adjusted. The material in the EcoEnd reduces the use of primary aluminum and increases the proportion of recycled materials, such as used beverage cans (UBC), so that it matches the composition of the can body more closely. Therefore, at the point of melting, the material of the EcoEnd and the can body can be considered the same mono-material. After it melts, the composition can be adjusted, and the characteristics of the lid and the can body can be differentiated. The development of the EcoEnd has made it possible to circulate a large amount of recycled materials in the lid, which was previously challenging, through postmelting composition adjustment and manufacturing techniques. In the future, more recycled materials will be used in the lid, leading to a reduction in GHG emissions due to the decrease in primary aluminum usage. The new aluminum material circulation flow realized by EcoEnd is as follows:

When the same material as that used in the can body is used for the lids, it is generally necessary to increase the lid's thickness to compensate for the lack of strength due to the increased amount of recycled material.

By combining the material manufacturing technology by UACJ and the lid forming technology by Toyo Seikan, EcoEnd has achieved the same quality performance as the current lids, even with increased use of recycled materials. Because there is no change in the thickness of the lid,*4 there is no need to change the equipment that attaches the lid after beverage filling, allowing for smooth replacement.

Our company and UACJ signed a business partnership agreement on February 6, 2023, aiming to further promote aluminum can horizontal recycling. The development of EcoEnd is also part of this partnership. Going forward, we will continue to strive for further promotion of aluminum can horizontal recycling and the reduction of greenhouse gas emissions throughout the entire supply chain through this business partnership.

*2 According to Toyo Seikan's investigation.

*3 The calculation is based on the GHG reduction per unit of EcoEnd and the actual production results of the current specification for stay-on-tab can lids manufactured by Toyo Seikan in the fiscal year 2019.

*4 This refers to EcoEnd for the domestic market. Development for the international market is currently underway.

For inquiries about this press release, please contact

Nakanori / Kakimoto

Corporate Communication Group

Sustainability Department

Toyo Seikan Group Holdings, Ltd.

(Email) tskg_contact@tskg-hd.com