The recent rise in public awareness of sustainability has increased demand for cans made of aluminum, an infinitely recyclable material. We are undertaking a project to introduce the “Compact Canmaking System for aTULC,” an unparalleled can production system developed by the Group to allow for a completely new business model, to American Canning LLC in Austin, Texas, which provides beverage packaging supplies and filling equipment for craft brewers across the fifty states of the United States.

As part of the Group’s strategy to expand the value chain into engineering, filling, and logistics areas based on its packaging operations, group companies including Toyo Seikan, Stolle Machinery Company and Toyo Seikan Group Holdings are currently working on a project to introduce the Compact Canmaking System for aTULC to American Canning. The new production line is expected to start up in January 2023.

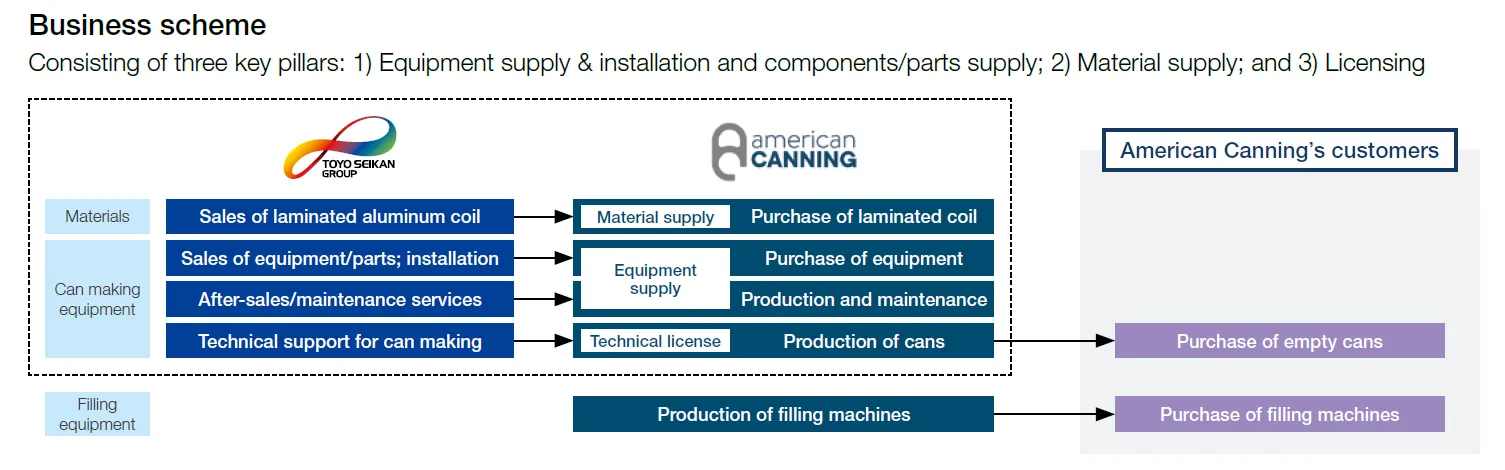

American Canning provides empty cans and other packaging materials and filling equipment and services for approximately 5,500 beverage brand owners across the fifty states. In the project, we will supply the company with can manufacturing equipment and maintenance and technical support, realizing profits from providing 1) can making equipment and parts and engineering services, 2) can materials, and 3) technical license for can making.

Through this opportunity, we will seek, together with American Canning, to put a new technology into practice and co-create a new business model, aiming to achieve continuous growth in the engineering field. By expanding the application of our proprietary, environmentally-conscious technologies for aluminum can manufacturing and engineering, we will contribute to creating a sustainable society and solving social issues.

American Canning provides beverage cans and other packaging supplies and filling equipment for craft brewers. With its aim of building a more modern ecosystem that allows small brewers and beverage brands to thrive, in autumn 2020, the company launched a project together with the Toyo Seikan Group for creating an original scheme to supply cans to fillers. In June 2022, we invited four key persons, including CEO and COO, from the company to Japan, and worked with them for five days through a plant tour, technical meetings, and discussion on a marketing plan in the U.S., among others, to achieve the project.

Since the announcement of a new plant construction in December 2021, American Canning has been promoting a technical campaign of aTULC through trade shows and various media. In May 2022, the company and Toyo Seikan participated in the Craft Brewer Conference & BrewExpo America, holding business meetings and distributing visitors a total of 1,000 sample cans of aTULC. American Canning will continue with its campaign for its customers across the United States until the new can making line begins full-scale operation in January 2023.

Mr. David Racino CEO, Co-Founder American Canning LLC

Mr. Mike Daniel COO, Co-Founder American Canning LLC

In mid-2020, a printing engineer and designer at American Canning found and bought Dark Horse wine, produced by E. & J. Gallo Winery and packaged in Toyo Seikan’s metal can, aTULC. Impressed by the can that allows for high-quality surface decoration, we immediately made an inquiry via Toyo Seikan’s website.

We started meeting with the company in autumn 2020 and had negotiations over two years. What made us decide to introduce the compact-type aTULC manufacturing system was our confidence that Toyo Seikan has competence and passion to fully support our growth into a world’s leading can manufacturer. We also focused on the environmental performance and sustainability of the aTULC production process, which should be of great importance to U.S. consumers.

We believe that aTULC is the best aluminum beverage can on the planet.

When our customers, such as craft breweries, wineries, and distilleries, pack their high-quality products in aTULC, consumers’ accessibility to their products will dramatically improve.

Satoshi Nishino

Head of Sales

Executive Officer

Toyo Seikan Group Holdings, Ltd.

Director and Senior Executive Officer

Toyo Seikan Co., Ltd

PET bottle production requires a lower initial investment than conventional metal can production, and has a simpler process that allows easy operation. This has promoted a vertical integration in the beverage industry that enables fillers to produce bottles in their factories.

In the metal can sector, it is the Compact Canmaking System for aTULC that will build a vertical integration. The system using sustainable aluminum achieves a lower initial investment and a simpler manufacturing process with a dry can forming method, realizing a model of local production for local consumption in which an optimal scale of production is provided for each area of demand. With the system introducing smaller production lines best suited for local demand, we expect the new model to help reduce CO2 emissions during production and transportation and contribute to a circular economy.

Shigenori Mori

Manager, Sales Administration Office

Toyo Seikan Co., Ltd.

Exporting aTULC for wine to the United States, which began in 2019, has led us to find a valuable partner, American Canning. It was our first significant step to expand into a global niche market with Toyo Seikan Group’s technologies.

I was convinced that the value of Japanese technologies would be globally recognized when American Canning’s staff visited Japan to meet and talk with project members from Toyo Seikan. This should be a major driving force for us to further grow in the future. We will continue to strive to become the best partner not just for overseas businesses, but also for Japanese companies that aim to expand globally.