2025.02.14

Management/Business

Comprehensive partnership agreement signed by Kashima City, REFINVERSE, Mitsubishi Chemical, Toyo Seikan Group, Kewpie, and KASUMI for six-party partnership to promote closed-loop recycling of plastic packaging

— Japan’s first* circular economy for caps of dressing bottles —

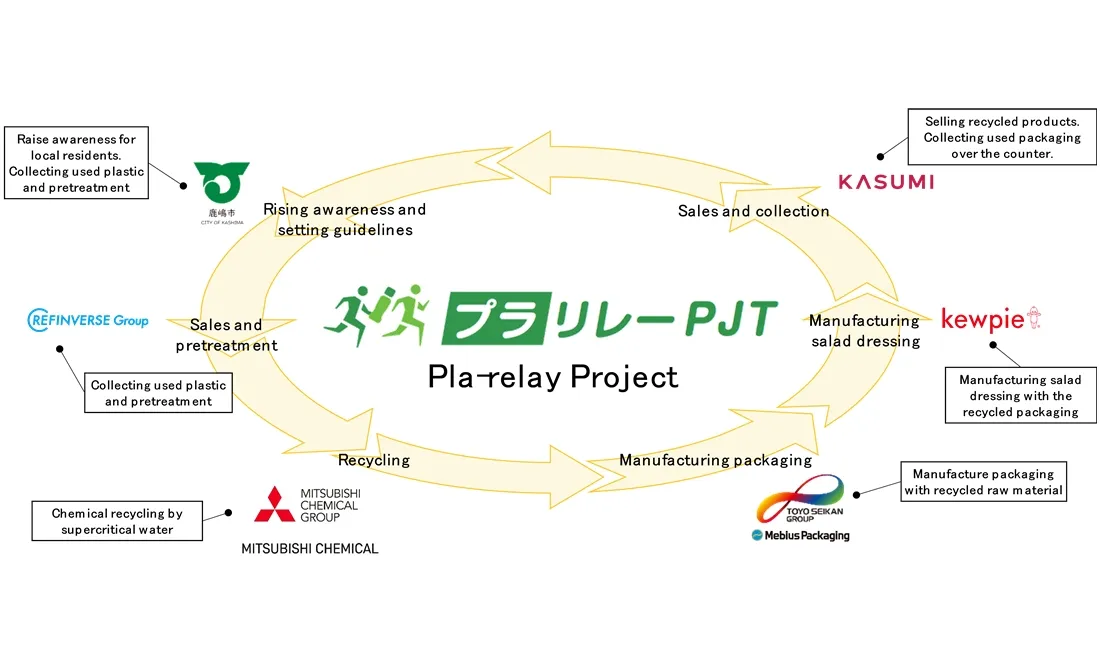

Dubbed the “Pla-relay Project,” it is the first closed-loop recycling of packaging project in Japan that leverages the unique strengths of a local government, a waste collecting company, a chemical manufacturer, a packaging manufacturer, a food manufacturer and a supermarket.

* The first project in Japan to use resin derived from recycled plastics converted into oil processed by supercritical water (mass balance approach)

As the recycling of plastic packaging and containers is essential to achieve a sustainable society, local governments, manufacturers, and retailers are promoting a variety of recycling projects. However, unlike containers that are easy to sort and send to mechanical recycling1, such as cans, PET bottles, glass bottles, and cardboard, plastic containers are difficult to sort, collect, and recycle by material type since a single container can be composed of different materials, even though they may appear similar.

To address this issue, the companies that specialize in the manufacturing, sales, collection and recycling of plastics agreed to collaborate and promote the circulation of plastic packaging using chemical recycling (also known as advanced recycling)2 in Kashima City.

1 Recycling methods that involve washing and shredding of used plastics to turn them into a material mechanically.

2 Recycling methods that involve chemically breaking used plastics down to raw materials such as oil, gas, and monomer as raw materials of plastics.

In this project, the parties will develop a circular model to chemical recycle caps and inner plugs of salad dressing bottles, items that are used in daily life. Caps and inner plugs of salad dressing bottles will be collected experimentally at public elementary schools in Kashima City and REFINVERSE will collect and perform the pretreatment of the used caps. Mitsubishi Chemical will then convert the pretreated caps into raw material for chemicals at its new chemical recycling plant, which will in turn be transformed into plastic resins at Japan Polypropylene and Japan Polyethylene. Mebius Packaging, a subsidiary of Toyo Seikan Group, will mold the plastic resin into caps and plugs for bottles, which Kewpie will use in their salad dressing bottles. Finally, KASUMI will sell the finished products at its Kashima Stadium Store, returning the plastics into the hands of the residents of Kashima City. The finished products, which use the mass balance approach3, will be available for sale4 around the summer of 2025.

3 The mass balance approach attributes credit to recycled materials based on their input amount for production that are manufactured using a mix of fossil-derived materials and recycled materials.

4 The products will be available in a limited number and for a limited time.

During periods before and after the pilot, opportunities to research and study plastic resources, tours of participating companies’ plants, and recycling education programs will be offered to public elementary schools and junior high schools in Kashima City.

Furthermore, the six parties plan to jointly create and publish a “validation report on the closed-loop recycling of plastic packaging” by March 2026, based on issues specified and feedback obtained through the project.

Roles of each company/organization in the project are as follows:

- The table can be scrolled left or right.

| Company/Organization | Role | Description |

|---|---|---|

| Kashima City | Setting the guidelines and rising awareness | Rise awareness of plastic recycling for local elementary schools, etc., and set guidelines through consultation with local communities |

| REFINVERSE | Collecting used plastics and pretreatment | Collect waste plastics in Ibaraki Prefecture and perform pretreatment (such as sorting and washing) |

| Mitsubishi Chemical | Recycling | Turn collected used plastics into oil by chemical recycling and then the oil is processed to raw materials for group companies Japan Polypropylene Corporation (“Japan Polypropylene”) and Japan Polyethylene Corporation (“Japan Polyethylene”) |

| Toyo Seikan Group | Manufacturing packaging | Manufacture packaging using recycled raw materials at group company Mebius Packaging Co., Ltd. (“Mebius Packaging”) |

| Kewpie | Manufacturing salad dressing | Manufacture salad dressing with the recycled packaging |

| KASUMI | Selling products and collecting used packaging | Sell the products and collect used plastics over the counter |

The purpose of this pilot project, which will be carried out in 2025, is to validate and establish a framework for achieving a closed loop recycling process for post-consumer plastic waste within a specific area. The six parties will verify various matters and issues—such as the required quality and quantity of waste plastics, issues related to recycling, the various certifications and procedures that are required, and how to communicate the appeal of products made from recycled materials to consumers—and clarify the costs involved and methods of covering such costs. Then, based on the verification, the six parties will then endeavor to set guidelines by working with industries and local communities.