*1 Established in April 2020, this organization is composed of companies, universities, research institutions, and others related to nanocellulose.*3 It promotes the potential application and industrial-scale expansion of nanocellulose through technology development and dissemination via collaboration among industry, government, academia, cooperation, and business promotion among member companies, and to enhance Japan’s industrial competitiveness through international standardization. At this event’s NCJ booth, several NCJ member companies will exhibit under the theme “A Sustainable Future Life Brought by Nanocellulose.”

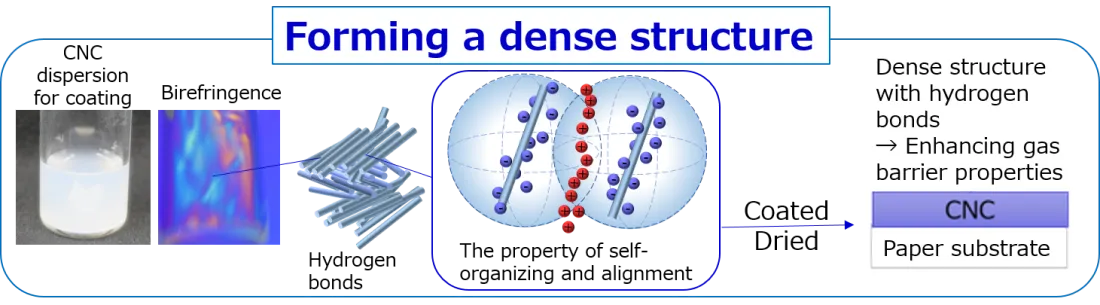

*2 Cellulose nanocrystals (CNC), a nanocellulose type, are nanosized crystalline structures extracted from cellulose microfibrils. Their diameter ranges from 3–50 nm, their length is approximately 100 nm to several micrometers, and their aspect ratio is smaller than that of cellulose nanofibers.

*3 Nanocellulose refers to cellulose fibers from plants that have been finely disintegrated into the nanoscale; they have widths of less than 100 nm. This is a generic term for cellulose-derived nanomaterials, including CNC and cellulose nanofiber (CNF). Mainly derived from plants such as wood, nanocellulose is lightweight, highly strong, environmentally friendly, and renewable. It has attracted global attention as a new biobased nanomaterial, and potential applications are being explored.

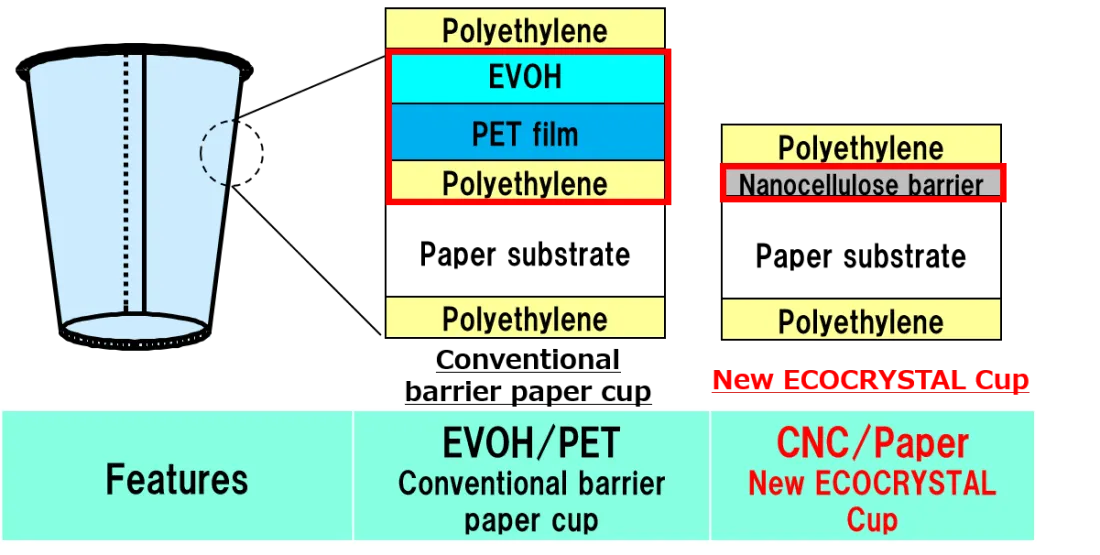

This product is an oxygen barrier paper cup that uses CNC, a high-performance and environmentally friendly new material, for the first time in Japan. By combining the technologies of our company and our consolidated subsidiary, Tokan Kogyo Co., Ltd. (President: Hironobu Tanabe), we have developed a barrier coating technology using CNC on paper, enabling the imparting of gas barrier properties to paper materials.

Coated CNCs self-organize and align to form a dense structure with low oxygen permeability that functions as a barrier. In addition to reducing the use of plastics that have conventionally been utilized as barrier films in barrier paper cups, this technology can reduce greenhouse gas emissions and help preserve the freshness and aroma of its contents.

At this exhibition, you can see three sample cups (coffee, yogurt, and popcorn) envisioned for potential product applications. Toyo Seikan Group aims to develop all-biomass barrier paper containers in the future and will continue to promote the substitution of further biomass materials in this product.

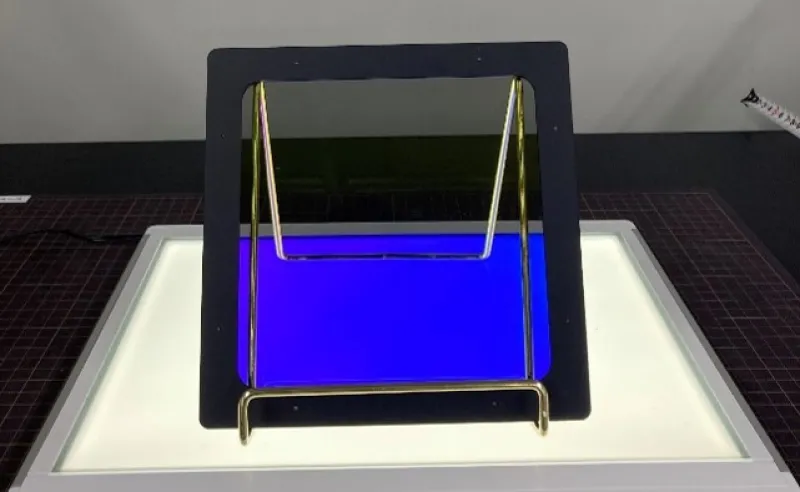

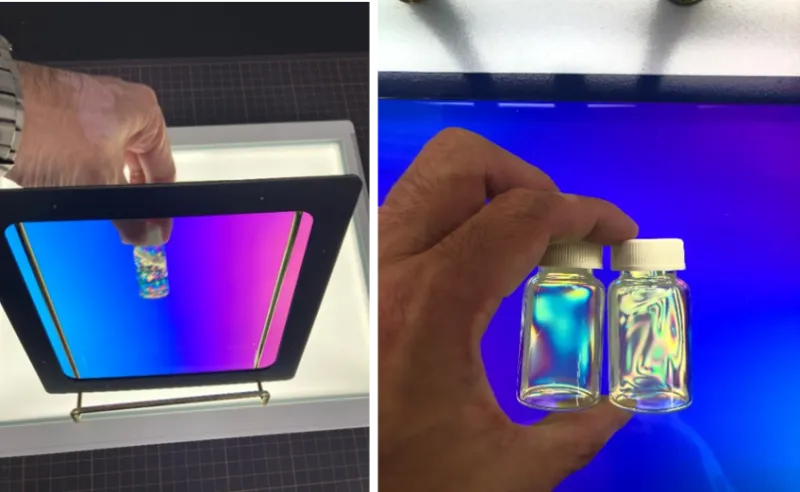

To help visitors experience the CNC’s oxygen barrier mechanism used in the New ECOCRYSTAL Cup, we will exhibit an observation device that visualizes CNC’s liquid crystallinity. When the dispersion of CNC used in the barrier coating is shaken and viewed through the polarizing plate of this device, aurora-like changes in color and light can be observed. This phenomenon occurs because CNC behaves like a liquid yet interacts, self-organizes, and aligns with one another; this affects light transmission and refraction, which causes birefringence. Consequently, these changes appear as color and pattern variations.

Similarly, we will also exhibit a comparison of CNF dispersion that has barrier properties and CNC dispersion with improved barrier performance. This will allow visitors to observe viscosity and polarization differences.

・Exhibition Period: Tuesday, June 10 to Monday, June 16, 2025

・Exhibition Location: Expo 2025 Osaka, Kansai, Japan, Future Life Village, Future Life Experience

・Exhibiting Organization: Nano Cellulose Japan (Our company will participate as a member company)

・Exhibition Title: “Wow, Wow, Wow, Nanocellulose”

・Our Exhibits: Oxygen barrier paper cups “New ECOCRYSTAL Cup” (three sample types), benchtop birefringence observation system, and CNC/CNF dispersion samples

Since its founding in 1943, Tokan Kogyo has produced a wide range of packaging containers using paper and plastic materials. As a leading company in the domestic market, it serves the diverse needs of customers and provides environmentally friendly products, particularly paper cups, to meet various requirements and lifestyles. The company’s management philosophy is to “create products and systems that harmonize with the needs of society and the natural environment and contribute to the improvement of living culture.” Tokan Kogyo therefore values the individuality and diversity of employees and strives to transform and create packaging containers that help in creating a sustainable society.