Open Up!Products and Services

Twist Off Cap

Nippon Closures Co., Ltd.

A glass bottle cap that can be easily opened and closed due to the good engagement of the protrusion at the bottom of the cap and the glass bottle.

•Significantly reduces greenhouse gas (GHG) emissions in the cap's printing, coating and finishing processes (the processes).

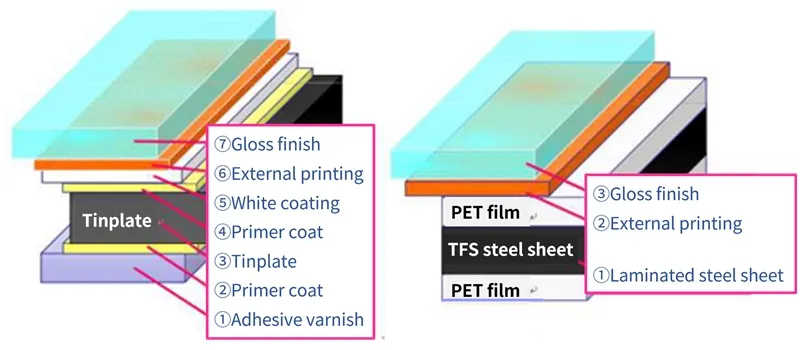

We used a metal plate with a white polyester film thermally adhered to the material for the cap. By utilizing the property of the polyester film to adhere directly to the sealing compound, we have significantly reduced the number of steps of the processes from the previous six steps in the processes to two steps. As a result, we achieved a reduction of approximately 65% in GHG emissions generated during the processes*.

* This calculation is based on the annual electricity and gas consumption for the processes of twist-off caps, and the total reduction effect over the cap’s life cycle is approximately 4.1%.

By using polyester film, the scratch resistance of the cap was improved compared to the caps applying the previous 6 steps of the processes. This reduces the risk of rusting. Furthermore, the leaching of organic compounds is minimized, and the absorption of flavor components is suppressed, allowing for the long-term preservation of the delicious taste of the contents.