Open Up!Products and Services

Lip Push Lid

Tokan Kogyo Co., Ltd.

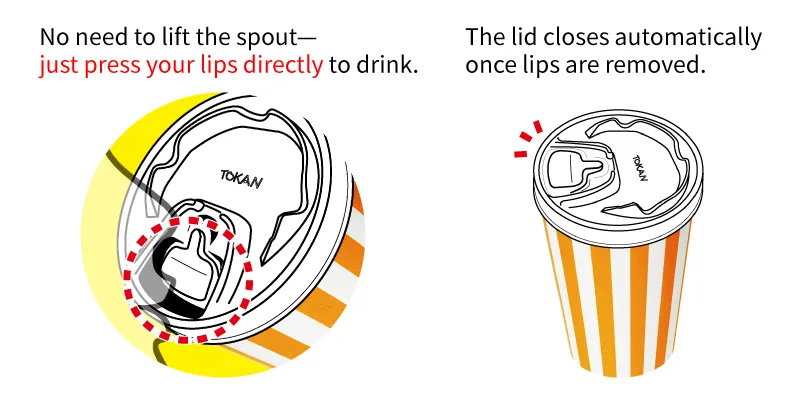

A lid for a drinking cup that allows easy drinking by lightly pressing the drinking spout with the upper lip.

•Pursuing new features and ease of use that were not available in conventional products.

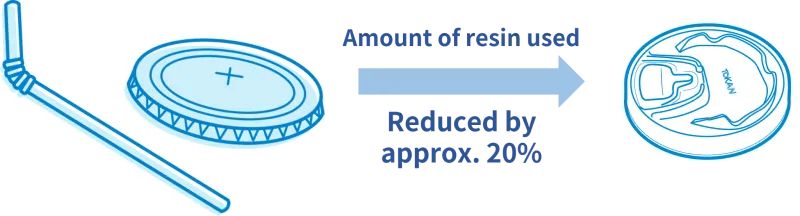

•Reducing the amount of resin used and the greenhouse emissions derived from the resin.

This is a hands-free lid that opens by lightly pressing the drinking spout with the upper lip. It allows people to drink by simply tilting the cup, making it relatively easy to use even for seniors or those with limited hand or finger mobility.

Once the lips are removed, the lid automatically closes to prevent dust, insects, or leaks caused by movement or vibration.

Compared to conventional lids with straw (calculated as flat lid + resin straw total*1), this lid reduces resin usage by approximately 20%, resulting in a similar reduction of 20% in GHG emissions from resin production*2.

*1 Compared by weight with Toyo Seikan’s lids and straws of the same diameter

*2 GHG emissions estimated from resin raw material manufacturing

Katsuhiko Soma

Manager, Technology Development Division

Tokan Kogyo Co., Ltd.

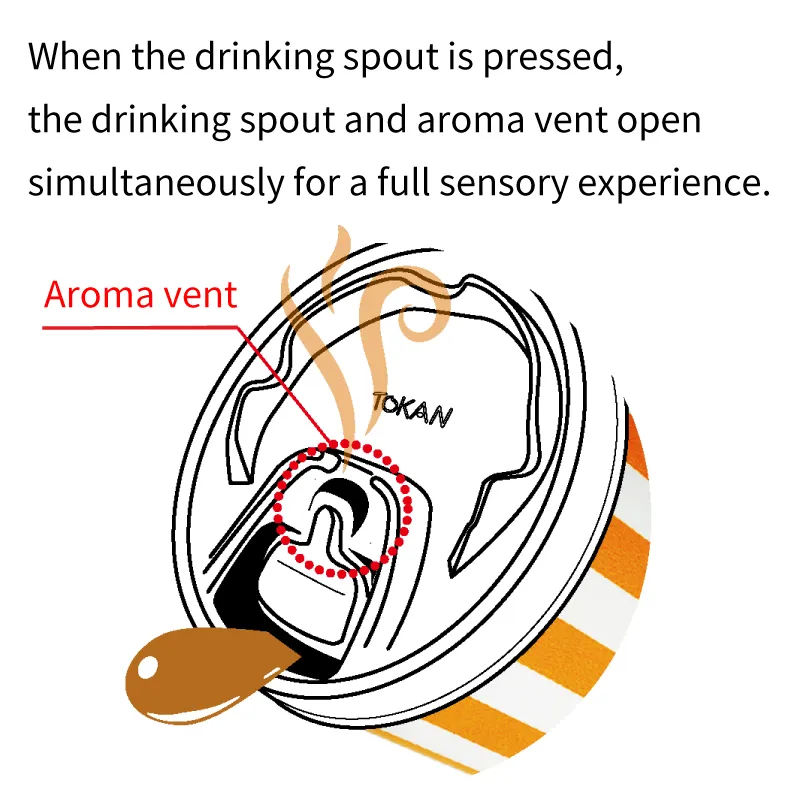

The initiative began with a request from our customer (a convenience store) to reduce the amount of resin used in the lids of drinking cups. The customer had a challenge to reduce resin usage as part of their efforts to lower environmental impact, and we have been working on this step for some time. However there were liminations in maintaining the shape while reducing resin usage, which led to a decline in quality. Therefore, we decided to develop a new lid that could reduce resin usage while maintaining quality. Additionally, the customer requested an added feature that allows enjoying the aroma of coffee while drinking which promoted the start of this development.

During manufacturing, the drinking spout and aroma window are cut using a blade. One major challenge was adjusting the process so that even during mass production, the cuts would remain precise and consistent. We had to ensure the lid could be gently opened with the lips and would close again once the lips were removed. Through extensive testing during production trials, we finely tuned factors such as blade hardness, cutting angles, backing plate firmness, and the thickness of the connecting seams. Thanks to these efforts, we’ve been able to maintain product quality since its market release in 2023 and continue stable mass production into 2024.

We’ve received a lot of positive feedback, such as:

“It’s easy to drink from.” “You can really enjoy the aroma.” “It’s lighter.” “It’s nesting issue (where lids get stuck together when stacked) has been improved.”

Generally, the thinner a lid is, the more prone it becomes to nesting. However, this product solves that by incorporating small, randomly placed dimples that slightly misalign the lids when stacked, reducing the chances of them getting stuck—all without compromising the appearance.

I think this is a brilliant example of a completely new solution. What’s more, it adds value for consumers by incorporating an aroma window so they can enjoy the scent of their drink. Since this is a new drinking method, I believe that effectively educating and informing people about how to use it will be a key factor.