History

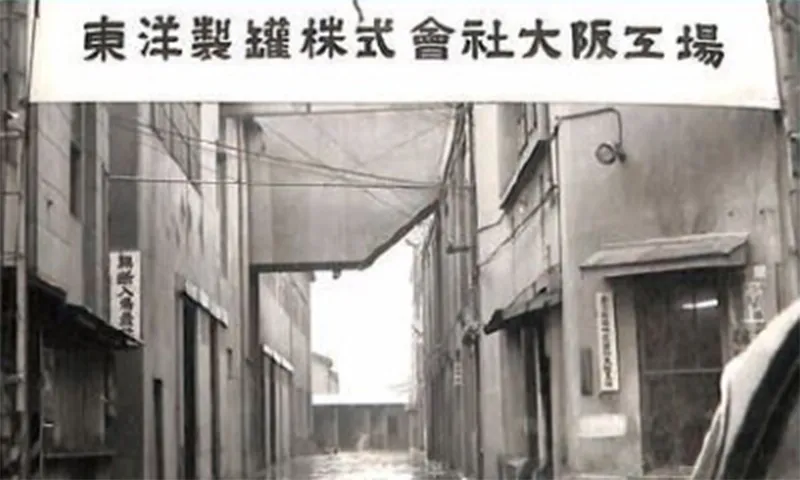

1917

Organization/Business

Toyo Seikan Co., Ltd. (now Toyo Seikan Group Holdings, Ltd.) is founded, with its head office and Osaka factory established in Osaka City (June 25th)

1919

product

Started manufacturing cans (No. 2 cans) using automatic can manufacturing equipment

1920

Organization/Business

Tokyo factory established

On the day of completion

1933

Organization/Business

Tobata Factory established

1934

group

Toyo Kohan Co., Ltd. is established

1935

Organization/Business

Listed on the Osaka Securities Exchange

1935

group

In response to the expansion of canned food exports, Japan's first private tinplate production begins.

This will enable domestic self-sufficiency in ingredients and contribute to a stable supply as canned goods exports expand.

Toyo Kohan, Ltd.

1937

Organization/Business

Shimizu Factory established

Shimizu Factory at the time of its establishment

Employees at the Shimizu Plant at the time of its establishment

1941

Organization/Business

Following the recommendation of a large joint group of can manufacturers, seven companies merged to form Toyo Seikan Co., Ltd. (now Toyo Seikan Group Holdings, Ltd.)

Saiwai Building (Toyo Seikan Headquarters) was relocated in 1941. Until it was rebuilt in 1980, it was adjacent to TOYO GLASS CO., LTD. headquarters (right in the photo). The headquarters functions were located here until it moved to the new headquarters building in 2012.

1943

group

Tokan Chemical Industry Co., Ltd. (now Tokan Kogyo Co., Ltd.) is established

Tokan Chemical Industry Co., Ltd. Company Founding Prospectus

1944

Organization/Business

Head office relocated to Chiyoda-ku, Tokyo

1949

Organization/Business

Listed on the Tokyo Stock Exchange

1949

group

Toyo Kohan Co., Ltd. is listed on the Tokyo and Osaka stock exchanges.

1950

group

Tokan Chemical Industry Co., Ltd. changes its name to Tokan Kogyo Co., Ltd.

1950

group

Nippon Ferro Co., Ltd. (now TOMATEC Co., Ltd.) is established.

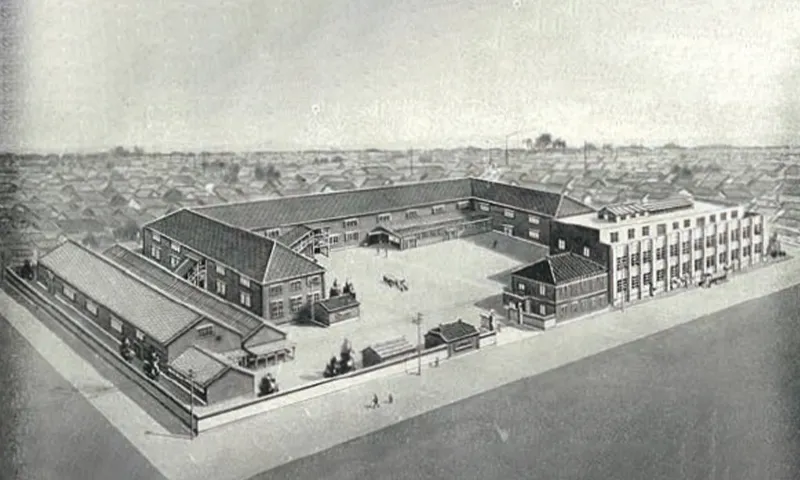

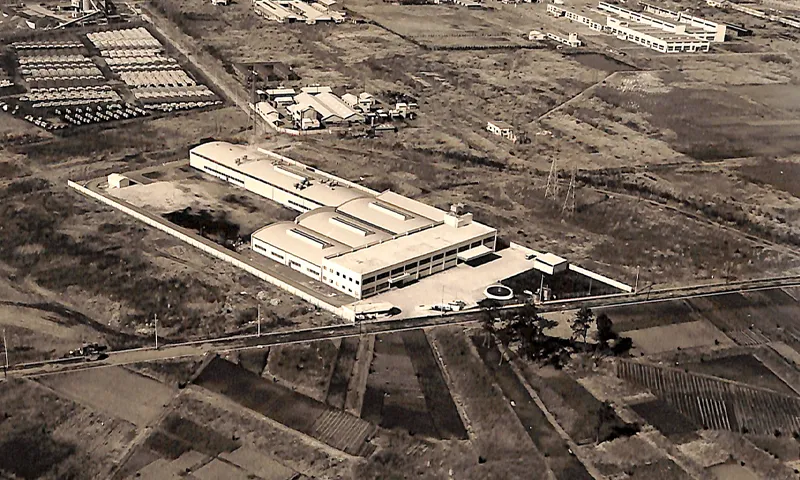

Osaka Factory completed in 1951

1952

product

Started production of Japan's first spray-type insecticide

Just a quick spray into the air will quickly eliminate pests.

1953

group

Shimada Glass Co., Ltd., the predecessor of TOYO GLASS CO., LTD., joins Toyo Seikan Group

1953

group

Toyo Aerosol Industry Co., Ltd. Toyo Aerosol Industry Co.

1954

group

Teikoku Crown Cork Co., Ltd. (now Nippon Closures Co., Ltd.) joins Toyo Seikan Group

1956

group

Shintoyo Glass Co., Ltd. (now TOYO GLASS CO., LTD.) is established.

1958

Organization/Business

Sendai Factory established

1958

product

Began production of Japan's first beer cans

1958

group

Started production of Fertilizer "F.T.E."

This environmentally friendly fertilizer contains six trace elements essential for plants in a vitrified form, making it safe, easy to use, and long-lasting.

TOMATEC Co., Ltd.

1959

group

Teikoku Crown Cork Co., Ltd. changes its name to Japan Crown Cork Co., Ltd. (now Nippon Closures Co., Ltd.)

1960

Organization/Business

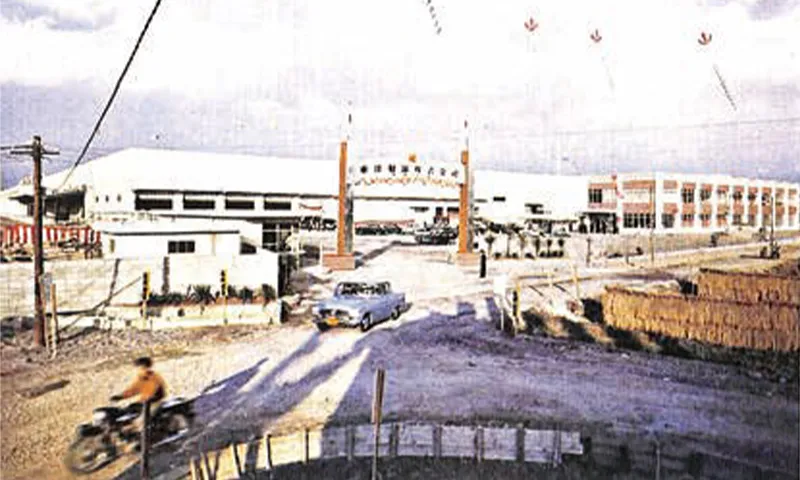

Ibaraki Factory established

1961

Organization/Business

Yokohama Factory established

1961

Organization/Business

Establishment of General Research Institute

1962

product

Started production of plastic bottles (for detergents)

1962

group

Toyo Aerosol Industry Co., Ltd. changes its trade name to Toyo Aerosol Industry Co., Ltd.

1963

group

Started production of PP caps

The bridge at the bottom of the cap breaks, allowing confirmation that the cap has been opened, helping to prevent tampering

Nippon Closures Co., Ltd.

1965

product

Introduced aluminum pull-tab lids

1967

Organization/Business

Kawasaki Factory established

1967

group

Shintoyo Glass Co., Ltd. changes its name to TOYO GLASS CO., LTD.

1969

group

Crown Seal Company Limited (now Crown Seal Public Co., Ltd.) joins Toyo Seikan Group

1969

product

Began production of the world's first retort pouches using aluminum foil

This container allows for pressure and heat sterilization and is the first in the world to be developed and put into practical use, allowing for distribution at room temperature.

1970

product

Started production of Toyo Seam cans

1971

Organization/Business

Saitama Factory established

1971

Organization/Business

Takatsuki Factory established

1972

Organization/Business

Chitose Factory established

1972

product

Started production of Lamicon bottles (for mayonnaise)

1973

Organization/Business

Hiroshima Factory established

1974

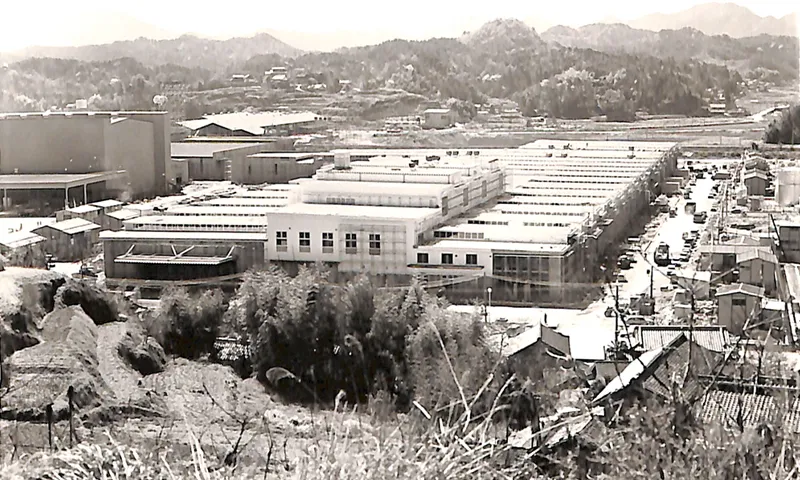

Organization/Business

Osaka factory relocated to Izumisano city

Osaka (Izumisano) Factory

1974

Organization/Business

Kiyama Factory established

1974

product

Started production of DI cans

DI (Drawn & Ironed) can

1976

product

Started production of push-in tab lids for carbonated drinks (202 diameter).

1977

Organization/Business

Ishioka Factory established

1977

product

Started production of DRD cans

1977

group

Crown Seal Company Limited (now Crown Seal Public Co., Ltd.) lists its shares on the Stock Exchange of Thailand.

1978

product

Started production of welded beverage cans

1978

product

Started production of PET bottles (500ml) for soy sauce

1978

product

Started production of Ramicon cups

The container is made from an oxygen-barrier sheet and can be stored for a medium to long period at room temperature, contributing to changes in eating habits.

1979

Organization/Business

Kuki Factory established

Completed Kuki Factory

1979

product

Started production of welded aerosol cans

1980

Organization/Business

Completion of the Sachi Building (Chiyoda-ku, Tokyo)

Scenes from the groundbreaking ceremony for the Saiwai Building

1982

product

Started production of PET beverage bottles

1983

Organization/Business

Sendai factory relocated to Minato, Miyagino Ward, Sendai City

1985

product

Started production of Phoenix cans

1985

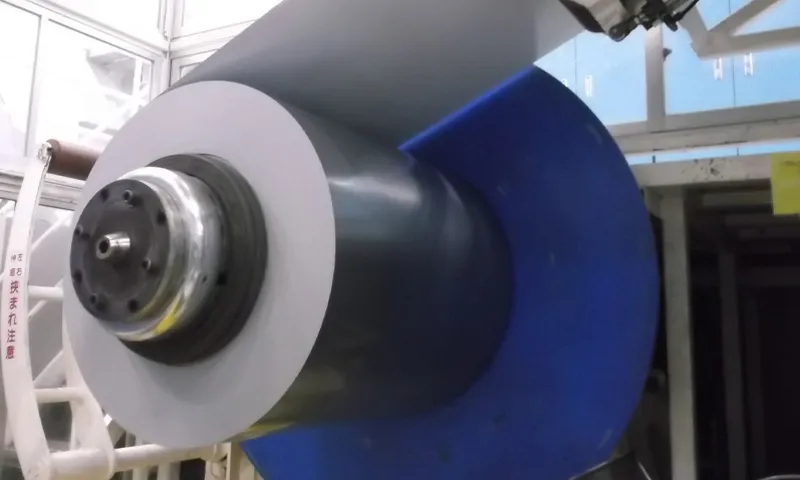

group

Started shipping laminated steel sheets (Hi-Pet)

This new environmentally friendly material contributes to the realization of Toyo Seikan, Ltd.'s highly environmentally friendly two-piece can "TULC (talc)."

Toyo Kohan, Ltd.

1988

group

Established Bangkok Can Manufacturing Co., Ltd.

1990

product

Started production of stay-on-tab (SOT) lids

1991

product

Started production of TULC (Toyo Ultimate Can)

1991

group

Started production of Ecology Bottle

Made from over 90% recycled cullet, it can be recycled into glass bottles over and over again

TOYO GLASS, Ltd.

1993

Organization/Business

Toyohashi Factory established

1993

product

Started production of colon cancer test containers

1994

product

Started production of Oxyguard (for cooked rice)

Oxygen-absorbing container "Oxyguard"

1994

group

Crown Seal Company Limited changes its name to Crown Seal Public Co., Ltd.

1995

product

Production of Pascal cans begins

1996

product

Started production of Moisture Guard (pouch with moisture absorption function)

1997

Organization/Business

Capital increased to 11,094,600,000 yen

1999

product

Started production of embossed beverage cans

1999

group

Started production of Universal Design Bottle

Glass bottles are designed from an ergonomic perspective, making them easier to hold and pour from.

TOYO GLASS, Ltd.

2000

Organization/Business

Shizuoka Factory established

2000

Organization/Business

Tokyo Factory integrated into Yokohama Factory

2000

group

Started production of ultra-lightweight returnable bottles

The bottle is designed with a narrowed body, making it easy to hold, and its resin coating makes it returnable. It is an ultra-lightweight bottle, the first container to receive the Good Design Award.

TOYO GLASS, Ltd.

2001

product

Started production of Oxyblock heat-resistant multi-layer PET bottles (for hot beverages)

2001

product

Started production of aluminum DI diamond cut cans

2001

product

Production of aTULC begins

2001

group

Started production of For Vehicle-Mounted Secondary Batteries Nickel-Plated Steel Sheet (Ni-Top)

Used as a key component of secondary batteries for HEVs and EVs, contributing to reducing environmental impact

Toyo Kohan, Ltd.

2002

product

Started production of double safety full-open lids

2003

Organization/Business

Tobata Factory integrated into Kiyama Factory

2003

group

Tokan Packaging System Co., Ltd. (now Nippon Tokan Package Co., Ltd.) established

2003

group

Nippon Ferro Co., Ltd. changes its name to Tokan Material Technology Co., Ltd.

2003

group

Started production of heat-shielding pigments (Near Infrared Reflective Pigment)

Black pigment that suppresses temperature rise caused by absorbing near-infrared rays contained in sunlight

TOMATEC Co., Ltd.

2004

group

Started providing DNA chips

A single chip can measure multiple genes simultaneously, contributing to the provision of effective treatments and extending healthy lifespans.

Toyo Kohan, Ltd.

2005

product

Started production of multi-block bottles (for mayonnaise)

2005

product

Started production of retort pouches with zippers

2005

group

Tokan Packaging System Co., Ltd. changes its name to Nippon Tokan Package Co., Ltd.

2006

product

Started production of TULC label embossed cans

2008

product

Started production of aroma dome cans

2009

Organization/Business

Shiga Factory established

2009

product

Fuel cell cartridge developed

2009

product

Developed a hairline-finished aerosol can

2009

group

n-FAS (nanofast) developed

This "ultrafine silver particle uniformly dispersed" material was jointly developed within Toyo Seikan Group and is expected to be used in a variety of applications as a deodorizing and antibacterial material.

TOMATEC Co., Ltd.

2010

Organization/Business

Takatsuki Factory integrated into Shiga Factory

2010

Organization/Business

Shimizu Factory integrated into Shizuoka Factory

2010

product

Started production of TULC mirror-finish label cans

2010

product

Started production of exterior cans for lithium-ion secondary batteries

2011

Organization/Business

Osaki Forest Building completed (Shinagawa-ku, Tokyo)

2011

group

Stolle Machinery Company, LLC joins Toyo Seikan Group

2012

Organization/Business

Head office relocated to Shinagawa Ward, Tokyo

2012

product

Started production of OxyGuard cups for corned beef

2013

Organization/Business

Transitioned to a holding company structure and changed the company name to Toyo Seikan Group Holdings, Ltd.

2013

group

Toyo Seikan Split Preparation Co., Ltd. inherited all of our business except for the group management business through a company split, and changed its name to Toyo Seikan Co., Ltd.

2013

group

Japan Crown Cork Co., Ltd. changes its name to Nippon Closures Co., Ltd.

2013

group

Started production of DUAL

The world's first system that can dispense two contents simultaneously with one push. Uses environmentally friendly nitrogen.

Toyo Aerosol Industry Co., Ltd.

2017

Organization/Business

100th anniversary

2017

group

Mebius Packaging Co., Ltd. is established

2018

group

Through a company split, Mebius Packaging Co., Ltd. took over the plastic bottle and plastic cap businesses, primarily for non-beverage applications, of Toyo Seikan Co., Ltd., Tokan Kogyo Co., Ltd., and Nippon Closures Co., Ltd.

2018

group

Following our tender offer for Toyo Kohan Co., Ltd., the company was delisted from the First Section of the Tokyo Stock Exchange (it became a wholly owned subsidiary of our company in August 2018).

2018

group

Started offering TSUME-TARO

A total solution for "containers + filling" for sake. No capital investment is required, and filling and production can be done in-house at the brewery.

Toyo Seikan, Ltd.

2019

group

Started production of easy-to-open containers

A spout cap with a ring on the side that increases the outer diameter, making it easier to grip and open.

Nippon Closures Co., Ltd.

2019

group

Started production of Plant-Derived Resin Cap

Beverage caps made from biomass materials (plant-derived plastics). Condiment caps and spout caps for pouches are currently under development.

Nippon Closures Co., Ltd.

2019

group

Eco Quick BOX now available

Thin cardboard cases for e-commerce. Compared to conventional cases, they use more than 10% less material and our proprietary box-making machine significantly reduces assembly work hours.

Nippon Tokan Package Co., Ltd.

2020

group

Tokan Material Technology Co., Ltd. changes its name to TOMATEC Co., Ltd.

2020

product

Supporting the development of sustainable food

Aiming to accelerate the development of new primary industries by collaborating with DAIZ, a startup developing "Miracle Meat," a plant-based meat made from germinated soybeans, and Shiok Meats, a startup developing cell cultures for shrimp and crustaceans.

2021

group

DAN DAN DOME now available

This foldable tent is made of cardboard and can be recycled after use. It can also be used outdoors thanks to a special lamination technique.

Nippon Tokan Package Co., Ltd.

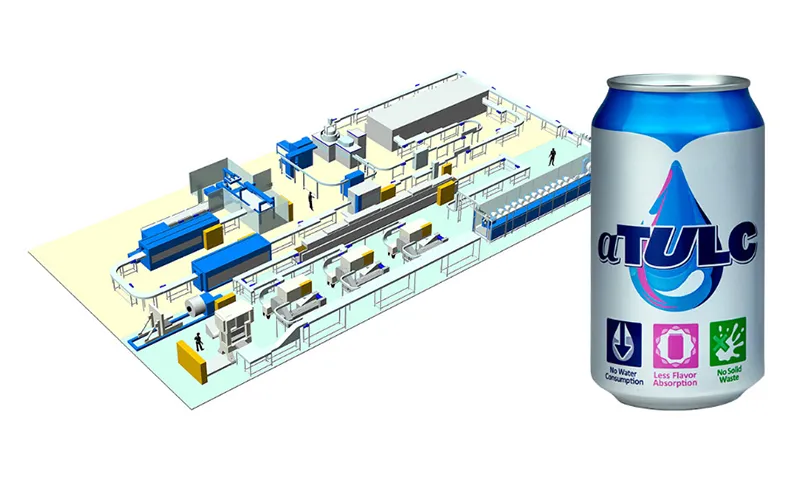

2021

group

Started offering aTULC Compact Canmaking Line

This can manufacturing system, which incorporates the environmentally friendly aTULC can manufacturing technology, achieves space savings, short construction periods, and low costs. It can produce 200 to 300 million cans per year at about half the speed of conventional large-scale lines.

Stolle Machinery Company, LLC

2021

group

Started production of bottles using recycled materials

Using recycled plastic in stretch-blow bottles contributes to the creation of a recycling-oriented society and reduces GHG emissions during the manufacturing process of plastic materials.

Mebius Packaging Co., Ltd.

2022

group

Launch of Next-Generation Aerosol (for drones)

It can be mounted on a drone using a dedicated discharge device (SABOT), enabling work using a drone in high or dangerous places.

Toyo Aerosol Industry Co., Ltd.

2022

product

Started sales of "Wellbag" Device for Closed-System Cell Cultivation

Cell culture vessel that enables the formation of uniformly sized spheroids in a closed system

2022

group

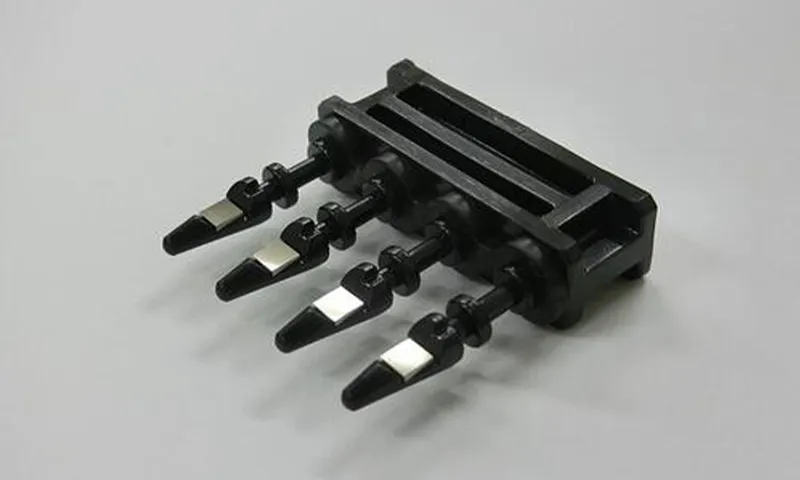

Started production of Finger Fitting Tabs

The opening tab of the easy-open end for food cans has a concave shape that fits comfortably on the fingers.

Toyo Seikan, Ltd.

2022

group

Sales of Lumisus begin

The cup is made of horizontally recyclable aluminum to reduce environmental impact. It is an environmentally friendly container that uses zero water during manufacturing.

Toyo Seikan, Ltd., Tokan Kogyo, Ltd.

2022

group

Started providing Re-CUP WASHER

Consumer-participation cup washer. Solves the material recycling challenge of "food waste." Circulates burnable waste as a resource.

Tokan Kogyo, Ltd.