Open Up!Products and Services

Powder for Electrostatic Glazing

TOMATEC Co., Ltd.

TOMATEC(Xiamen)Fine Material Co., Ltd.

Water-Free Enamel Glazing* Powder

●Since there is no alteration of components by water, the glaze's lifespan is extended.

●No water is used, eliminating the need for drying processes and wastewater treatment after glazing.

●High glazing efficiency with recyclable reclaimed powder.

* Applying glaze to steel plates to form a glassy coating for enamel production.

The powder for electrostatic glazing does not use water.

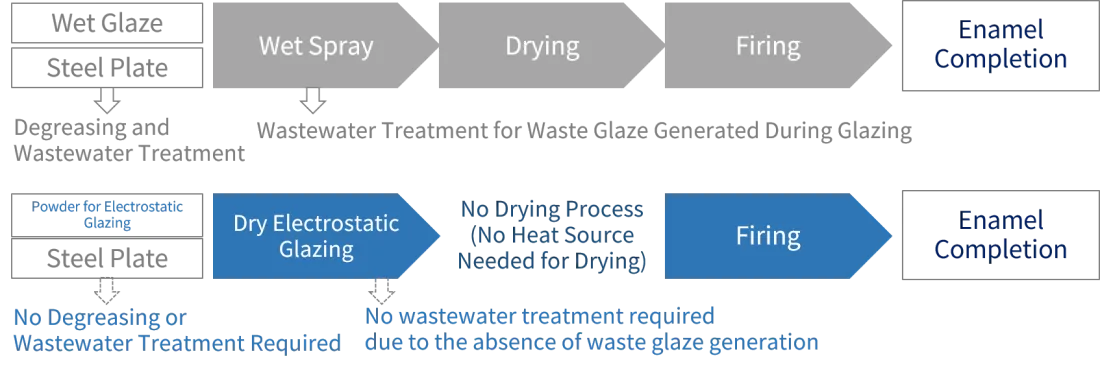

Traditional glazes (wet glazes) contain water and require pre-degreasing treatment for steel sheets with oil residues. However, the water-free powder for electrostatic glazing eliminates the need for degreasing.

As a result, wastewater treatment associated with degreasing and wet spray glazing can also be omitted.

Furthermore, since the drying process after glazing is unnecessary, this contributes to reducing labor and energy consumption.

- The table can be scrolled left or right.

| Wet Glaze | Powder for Electrostatic Glazing | |

|---|---|---|

| Condition of the Glaze | Slurry form (viscous state) | Powder form |

| Water | Contained | Not contained |

| Glaze Durability | Short | Long |

| Subsequent Processes | Drying process and wastewater treatment required | No drying required, no wastewater generated |

| Glaze Reusability | Basically not possible | Possible |

| Color Variations | Wide range available | Limited options available |

Conventional glazes containing water (wet glazes) require wastewater treatment; however, overseas, managing wastewater is challenging, leading many companies to adopt water-free powder for electrostatic glazing. This product’s full-scale development for overseas markets began with the establishment of the factory of TOMATEC Co., Ltd.’s subsidiary, TOMATEC(Xiamen)Fine Material Co., Ltd.

Members of TOMATEC(Xiamen)Fine Material Co., Ltd.

The powder for electrostatic glazing possesses various characteristics such as adhesion strength to steel plates, adhesion speed, and moisture resistance. To ensure stable quality under any environment, extensive testing has been conducted not only in the laboratory at the Xiamen factory but also repeatedly at customers’ sites, striving to develop products tailored to each customer’s requirements. Additionally, when some raw material costs surged during development, we adjusted the raw material formulation without compromising quality to reduce costs and meet customer demands.

Our powder for electrostatic glazing is primarily used by barbecue grill manufacturers in China and Southeast Asia, home appliance manufacturers of ovens and microwaves, and component manufacturers for heat exchangers in thermal power plants. Competitors in this market are mainly based in Turkey and the United States, which are distant for customers in the Asian region. Therefore, our prompt technical support and troubleshooting services are especially valued by our customers.

We plan to develop new applications beyond improvements in surface gloss, barbecue grills, and heat exchanger components for thermal power plants. Since this product uses no water and contributes to energy savings during drying and automation of glazing, we aim to expand sales by increasing the range of applicable products.