Toward a Zero-Carbon Society

The progression of global warming due to rising concentrations of greenhouse gases (GHG) in the atmosphere has a significant negative impact on people's lives and society. Toyo Seikan Group is working to reduce GHG emissions in both its business activities, products, and services, and is contributing to the realization of a decarbonized society.

Integrated Information Disclosure Based on the Recommendations of the TCFD and TNFDScope 1 and 2 Reduction Initiatives

Renewable energy for electricity

As part of its efforts to reduce GHG emissions from its business activities, Toyo Seikan Group is promoting the introduction of solar power generation facilities.

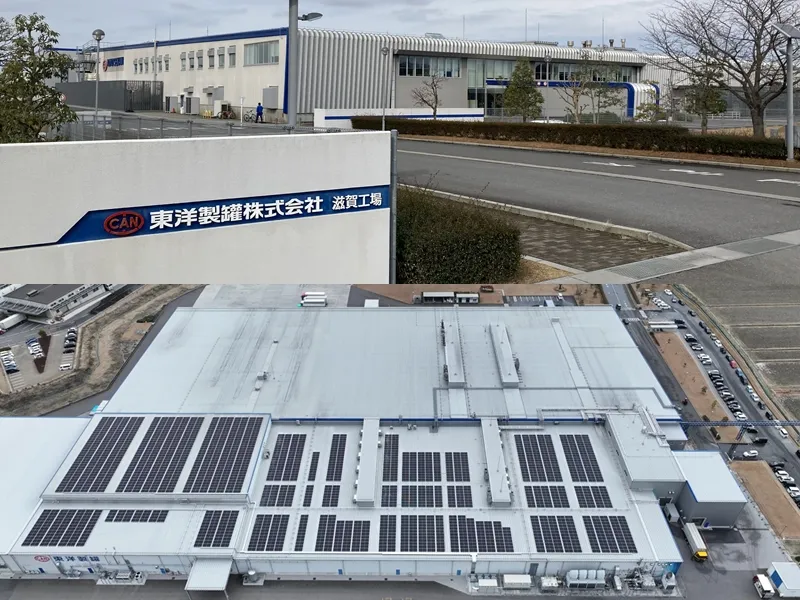

Installing solar power generation equipment (on-site)

In fiscal 2024, Toyo Seikan Group will install solar power generation facilities at eight new domestic bases and one overseas base.

FY2024 implementation results

Toyo Seikan Shizuoka Plant

Nippon Tokan Package Sendai Factory

Toyo Seikan Group Engineering Fukushima Plant

* Achieving virtually zero CO₂ emissions by combining solar power generation with the purchase of electricity using non-fossil fuel certificates

Next Can Innovation Co., Ltd.

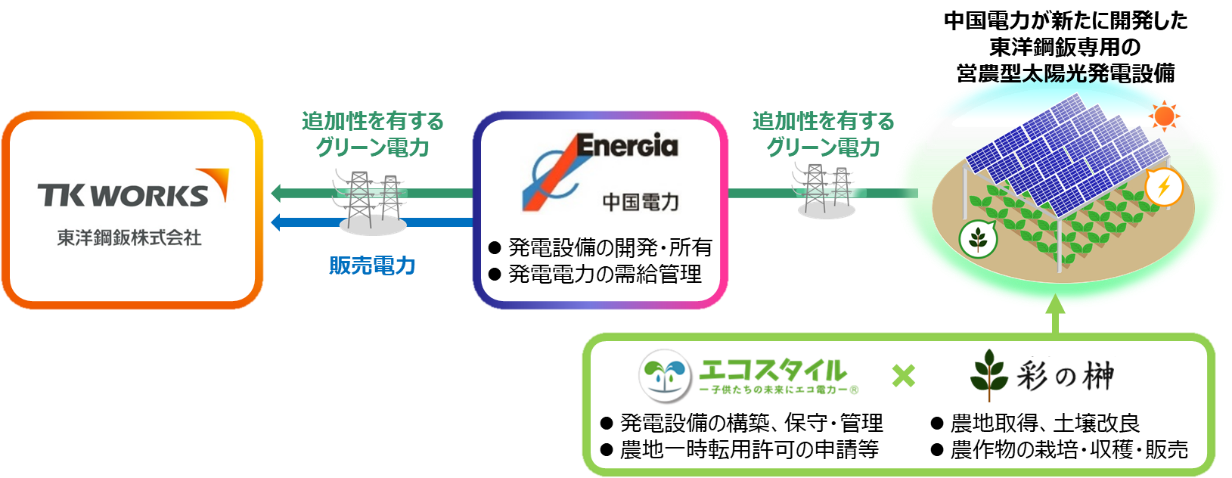

Installing agricultural solar power generation equipment (off-site)

Toyo Kohan has concluded an off-site PPA *1 agreement with Chugoku Electric Power Co., Inc. (hereinafter "Chugoku Electric Power") and is proceeding with the installation of agricultural solar power generation equipment. Chugoku Electric Power, in cooperation with Ecostyle Co., Ltd. and Sainosakaki Co., Ltd., will develop a new agricultural solar power plant with a total capacity of 64 MW and supply the generated electricity and environmental value to the Kudamatsu Plant. This off-site PPA utilizing agricultural solar power generation *2 is the first of its kind in the Chugoku region. The Kudamatsu Plant plans to replace approximately 20% of its electricity consumption with green power with additionality *3 by fiscal year 2030, which is expected to reduce GHG emissions by approximately 25,000 tons per year. This initiative is also expected to contribute to the revitalization of local agriculture by reclaiming abandoned farmland and improving agricultural management.

- Off-site PPA (Power Purchase Agreement): A power purchase agreement in which a power generation company installs solar power generation facilities in a location away from the power demand facility, and a retail electricity company supplies renewable energy electricity to specific consumers over the long term via the power grid.

- This is a method of balancing agriculture and power generation by installing solar power generation equipment in the space above farmland. This makes it possible to reclaim abandoned farmland, improve agricultural management, reduce carbon dioxide emissions from agricultural crop cultivation, and contribute to expanding the use of renewable energy.

- This refers to the effect of expanding the amount of renewable energy introduced by installing new solar power generation facilities, rather than using existing renewable energy facilities.

Energy conservation

Received the Smart Lifestyle Encouragement Award from Kawasaki City

On October 18, 2023, Mebius Packaging Kawasaki Plant received an Encouragement Award at Kawasaki City's 12th Smart Lifestyle Awards ceremony. The Smart Lifestyle Awards were established with the aim of promoting CO2 reduction and global warming countermeasures. Kawasaki City solicits submissions from citizens and businesses about various CO2 reduction actions, such as energy conservation and power saving, and recognizes outstanding efforts. The Kawasaki Plant's energy-saving activities at the plant were highly evaluated, leading to the award.

Heat source conversion and new technologies

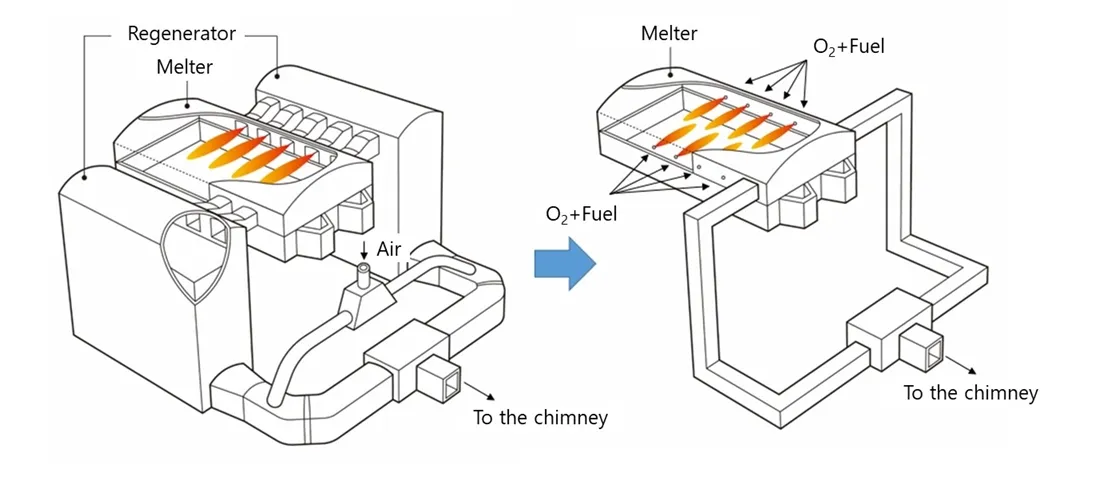

Introduction of oxygen combustion system to large glass melting furnace

TOYO GLASS CO., LTD. will change the combustion method from air combustion to oxygen combustion when it undergoes major repairs on one of its glass melting furnaces at its Chiba Plant, scheduled for December 2025. This will be the first time in Japan that an oxygen combustion method will be introduced to a large glass melting furnace for glass bottles, with a daily production capacity of over 200 tons. The introduction of this method is expected to reduce GHG emissions per furnace by approximately 20%. [Press release dated May 24, 2024] TOYO GLASS becomes the first in Japan to introduce oxygen combustion method to a large glass melting furnace - contributing to reducing greenhouse gas emissions -

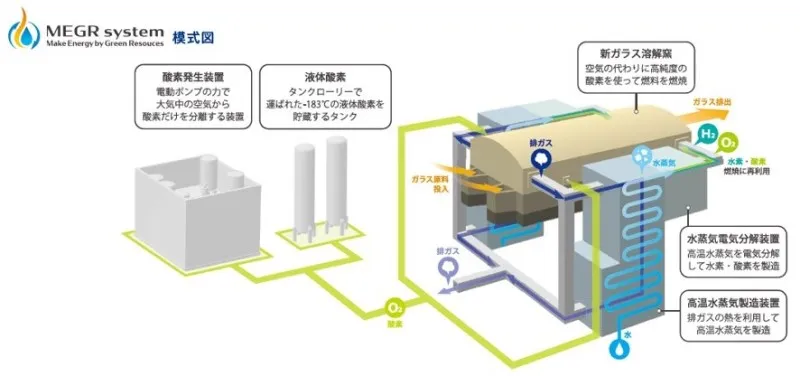

Development of the "MEGR system®," an oxygen-hydrogen combustion system that achieves long-term CO₂ reductions

Current glass melting furnaces use fossil fuels to melt glass at high temperatures, making reducing carbon dioxide emissions a challenge for the glass bottle industry. TOYO GLASS is developing an "oxy-hydrogen combustion furnace" that uses hydrogen, a fuel that does not emit carbon dioxide, in order to achieve the country's carbon neutral goal of 2050. [Press release dated June 28, 2024] TOYO GLASS 's proposal for "Development of a glass melting furnace equipped with an on-site hydrogen supply facility" has been selected as a NEDO project.

CO₂ capture

Three companies launch joint initiative to accelerate social implementation of CO₂ capture technology

Toyo Seikan Group Holdings has agreed to work together with JCCL Ltd. (hereinafter "JCCL") and Mitsui Bussan Plastics Co., Ltd. (hereinafter "Mitsui Bussan Plastics") to accelerate the early implementation of JCCL's CO₂ separation and capture technology.

With the aim of realizing a carbon-neutral society by 2050, CO₂ separation and capture technology is attracting attention. In order to quickly implement JCCL's energy-saving CO₂ separation and capture technology in society, Toyo Seikan Group will begin a joint initiative, utilizing the technological capabilities it has cultivated in the manufacture of packaging containers and the sales network of Mitsui Bussan Plastics.

[Press release dated March 31, 2025] JCCL, Toyo Seikan Group Holdings, and Mitsui Bussan Plastics begin joint initiative to quickly implement CO₂ separation and capture technology in society - Contributing to reducing environmental impact with low-cost, highly efficient CO₂ capture technology -

Scope 3 reduction efforts

Low-carbon raw materials and environmentally friendly products

Toyo Seikan Group considers the entire life cycle of its products and is promoting the development, manufacture, and sale of products with a low environmental impact. We have established unified Group evaluation criteria consisting of evaluation items at each stage of "raw material procurement," "product manufacturing," "transportation," "consumption," and "disposal/recycling," and are developing environmentally friendly products based on these criteria.

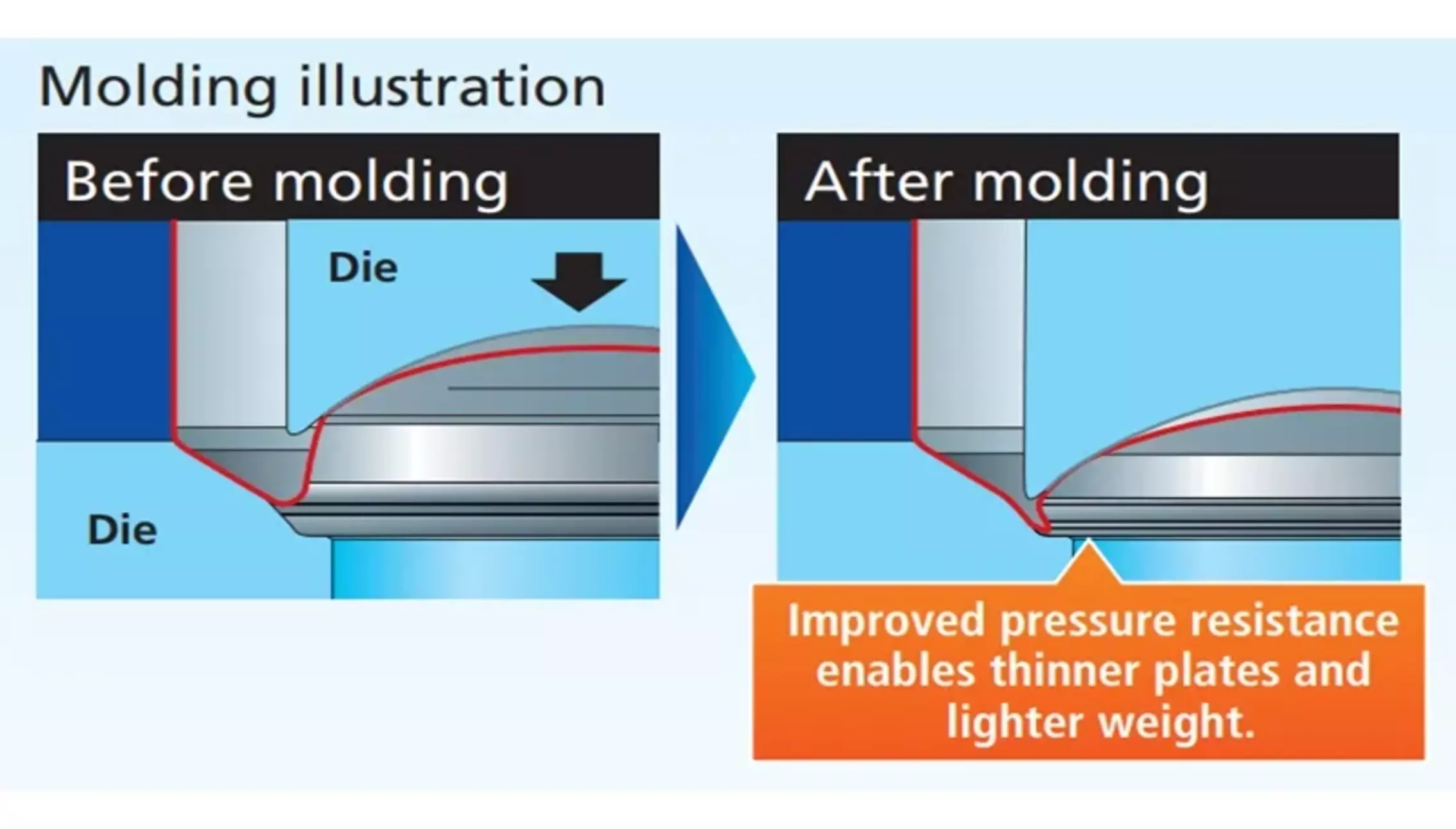

Sustainable products and services "Open Up! Products & Services" サステナブルな製品・サービスの認定制度Lightweight aluminum cans made possible by CBR (Compression Bottom Reform

Toyo Seikan has developed an aluminum beverage Compression Bottom Reform, which reforms and strengthens the bottom of the can, making it lighter. This technology is being used for aTULC cans with a body diameter of 202mm (190ml) and aluminum DI cans with a body diameter of 211mm (350ml and 500ml). This is expected to further reduce GHG emissions. [Press release dated March 26, 2024] Toyo Seikan Develops Japan's Lightest Aluminum Can and Begins Mass Production - Further Contribution to Reducing Greenhouse Gas Emissions - 【2024年8月29日プレスリリース】東洋製罐の世界最軽量アルミ缶 コカ・コーラ社の「ジョージア」で採用、量産開始-GHG排出量のさらなる削減を実現-

Significantly reducing greenhouse gas (GHG) emissions by increasing production of solvent-free pouches

Toyo Seikan Toyohashi Plant has added a solvent-free production line after developing one that can also be used to produce retort food pouches. Compared to solvent-based lines, solvent-free lines reduce GHG emissions by approximately 94% per line and also significantly reduce the amount of organic solvent used. In March 2024, this initiative was recognized, with the company receiving the Grand Prize at the Toyohashi Chamber of Commerce and Industry's 12th Environmental Management Awards *. Toyo Seikan will continue to work toward realizing a sustainable society through the creation of products that contribute to the environment.

- The award aims to popularize and spread the idea of environmental management by actively and widely disseminating the advanced and practical efforts being made by local companies while pursuing profits and reducing environmental impacts at the same time.

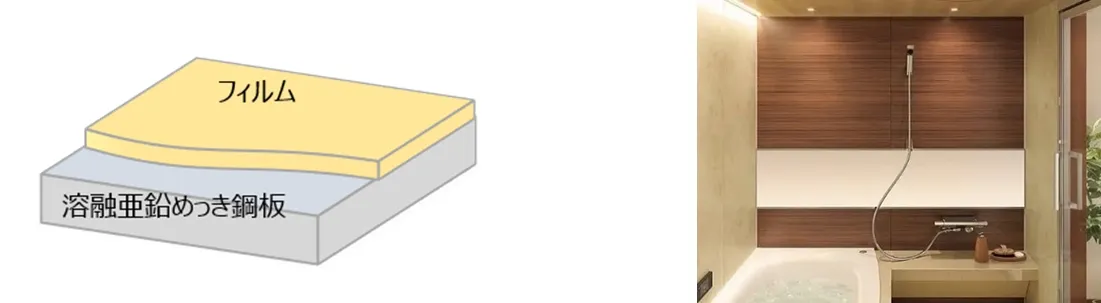

Developed a product that replaces conventional blast furnace-made steel plates with electric furnace-made steel plates

With the aim of contributing to the environment, Toyo Kohan has developed and begun selling a new hot-dip galvanized steel sheet used as the base material for resin-coated steel sheets (product names: Vinytop and Finetop) that replaces the conventional blast furnace-made base sheet with electric furnace-made base sheet.

This initiative will contribute to reducing Toyo Kohan 's Scope 3 emissions, and is also expected to help reduce the Scope 3 emissions of customers who use resin-decorated steel sheets.

[Press release dated August 1, 2024] Toyo Kohan develops and begins sales of new environmentally friendly resin-decorated steel sheets

Modal shift and new technologies

Initiatives to reduce the environmental impact of logistics

Toyo Seikan Group strives to reduce GHG emissions from logistics by proactively implementing measures to reduce the environmental impact of its transportation and warehousing operations. In transportation and delivery, we implement initiatives such as formulating production plans at the plants closest to our customers, leveraging our nationwide bases for highly efficient transportation and delivery, promoting the use of eco-tires, utilizing trailers and large vehicles to increase loading rates, utilizing return trips after deliveries, and implementing joint deliveries with customers and partner companies. In warehousing, we are also introducing energy-saving equipment and developing hub warehouses to store inventory between our production bases and customer clusters. In addition, in response to the serious truck driver shortage in the logistics industry, we support and promote the "White Logistics" initiative, which aims to achieve sustainable logistics. We believe this initiative also contributes to reducing environmental impact.

Promoting modal shift

Toyo Seikan Group is promoting a modal shift to rail and marine transport, which emit less GHG than trucks. While taking into consideration the characteristics of the goods being transported, we are working to reduce environmental impact and resolve issues such as the shortage of truck drivers.

Major initiatives to date

*The table can be scrolled left and right.

| October 2015 |

TOYO GLASS Logistics |

Uses large 31ft containers for efficient transport |

|---|---|---|

| December 2017 |

Toyo Seikan |

Uses 31ft containers |

| November 2018 |

Toyo Moebius |

Received the 5th Modal Shift Best Business Award (Grand Prize) |

| September 2019 |

Tokan Logitec |

Certified as a "Comprehensive Efficiency Plan" under the Ministry of Land, Infrastructure, Transport and Tourism's Logistics Comprehensive Efficiency Act |

| April 2021 |

Toyo Seikan |

Certified as a "2020 Eco-Ship Modal Shift Business Certified Business" |

| October 2024 |

Tokan Kogyo |

Two 31ft containers introduced |

| July 2025 |

Tokan Kogyo |

Demonstration of "modal combination" combining autonomous trucks and freight rail will begin between Kanto and Kyushu on July 14, 2025. Tokan Logitec, Zenkoku Tsuun, Japan Freight Railway Company, and T2 will begin the first "round trip" demonstration of "modal combination" combining autonomous trucks and freight rail between Kanto and Kyushu, aiming for Level 4 autonomous transport in 2027. |

Other Initiatives

Promoting 3Rs and mitigating climate change with container and packaging-related organizations

Toyo Seikan Group manufactures container packaging for seven of the eight materials used in Japan for container packaging (steel cans, aluminum cans, plastic containers and packaging, PET bottles, paper containers, paper beverage cartons, cardboard, and glass bottles). As a key member, the Group contributes to the individual material-related organizations and their coalitions that promote the 3Rs by serving as directors, committee members, and contributing activity funds (membership fees), and is engaged in activities to promote the 3Rs and reduce greenhouse gas emissions to mitigate climate change.

In October 2020, the Japanese government announced its "2050 Carbon Neutrality Declaration," which sets a goal of realizing a carbon-neutral society and achieving net-zero greenhouse gas emissions by 2050. In response, Toyo Seikan Group changed its goal from realizing a "low-carbon society" in 2021 to realizing a "carbon-neutral society" by 2050, and revised its medium- to long-term target for fiscal 2030 upward. Toyo Seikan Group also supports national climate change-related legislation, such as the Act on the Rationalization of Energy Use (Energy Conservation Act) and the Act on Promotion of Global Warming Countermeasures (Global Warming Act), and submits annual reports to the government on energy consumption, progress toward energy-saving targets, and greenhouse gas emissions. The Group also supports the government's efforts to implement the TCFD recommendations and discloses information about them.

Obtaining ZEB certification

Toyo Seikan Group is promoting the acquisition, development, and construction of buildings with high environmental performance, including energy-saving features, and is working to reduce the environmental impact of the entire group's business activities.

Toyo Mebius, which is engaged in truck transportation and warehousing businesses, began operations at the Kumagaya Logistics Center, a logistics warehouse built in Kumagaya City, Saitama Prefecture, in April 2023. The facility has been highly praised for its excellent energy-saving performance and has received ZEB certification. ZEB certification is awarded when a building aims to achieve zero annual energy consumption (including negative energy consumption) by combining energy conservation and energy creation.

- ZEB certification: Obtained the highest "ZEB" rank

ZEB (Net Zero Energy Building) is a certification given to buildings that aim to achieve zero annual primary energy consumption while maintaining a comfortable indoor environment.

Definition of ZEB (Ministry of the Environment website) - BELS certification: Obtained the highest rank of 5 stars

BELS (Building-Housing Energy-efficiency Labeling System) is a public rating system that evaluates the energy-saving performance of buildings based on their primary energy consumption on a five-point scale (★ to ★★★★★) in accordance with standards set by the Ministry of Land, Infrastructure, Transport and Tourism. - CASBEE Real Estate Certification: Received A rank in the building evaluation

CASBEE (Comprehensive Assessment System for Built Environment Efficiency) is a system led by the Ministry of Land, Infrastructure, Transport and Tourism that evaluates the overall environmental performance of buildings from the perspectives of environmental friendliness, comfort, landscape, etc.

Development of negative electrode current collector for next-generation batteries certified as "Supply Security Plan for Storage Batteries" by the Ministry of Economy, Trade and Industry

Toyo Kohan 's development of anode current collectors for next-generation batteries, which it is working on at its Kudamatsu Plant in Yamaguchi Prefecture, was certified as part of the Ministry of Economy, Trade and Industry's "Supply Security Plan for Storage Batteries" on December 20, 2024. Toyo Kohan will make maximum use of the government support that has been certified this time to advance development, aiming to make an investment decision for future mass production (storage batteries equivalent to 3GWh/year or more) by the end of fiscal year 2027, contributing to the spread of long-life, highly efficient storage batteries and strengthening the foundation of the supply chain for storage battery components and materials. [Press release dated December 24, 2024] Toyo Kohan 's development of anode current collectors for all-solid-state batteries has been certified as a "Supply Security Plan for Storage Batteries" by the Ministry of Economy, Trade and Industry.