Risk Management

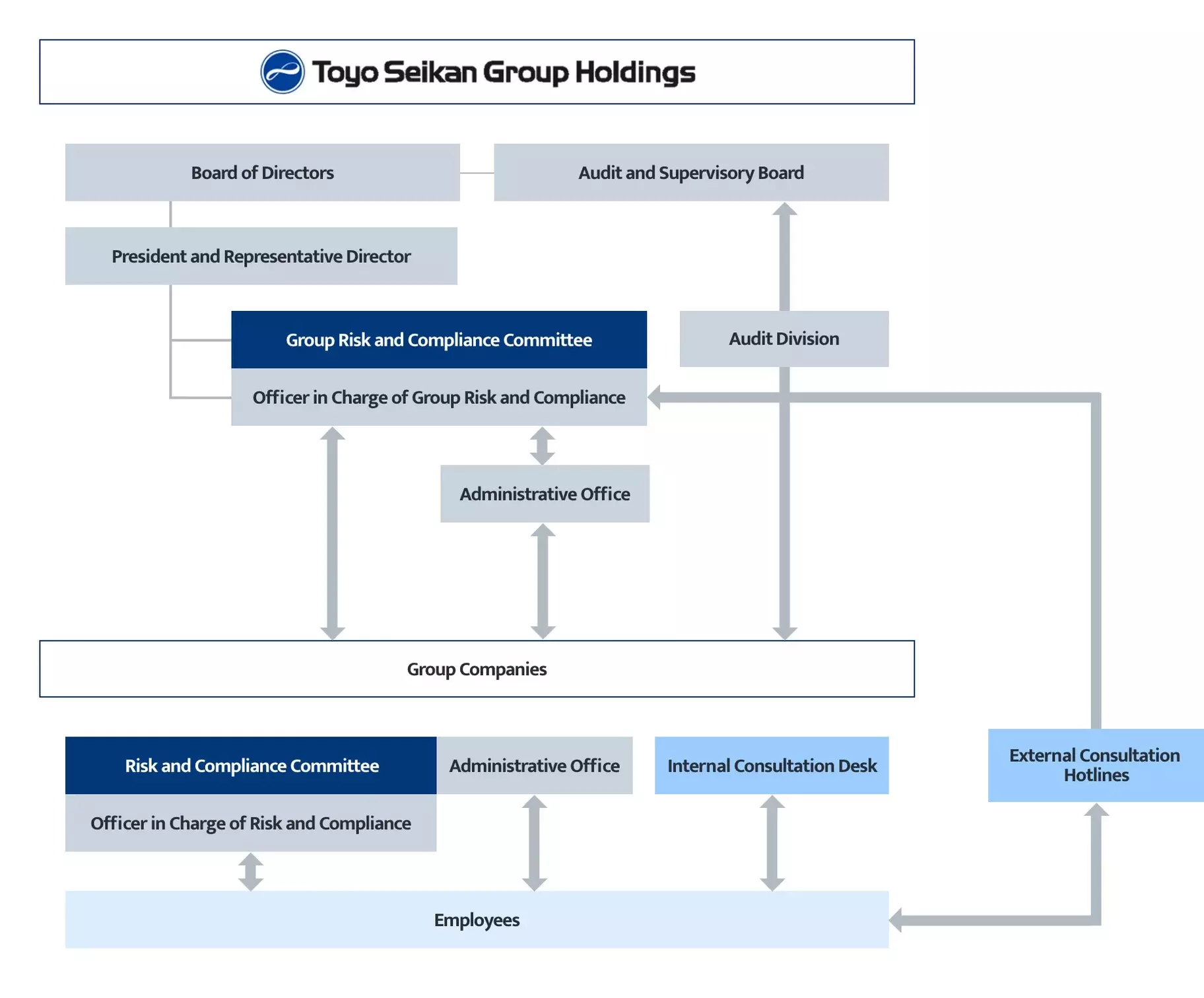

Toyo Seikan Group 's Risk Management System

Toyo Seikan Group is committed to risk management based on the Group Risk and Crisis Management Regulations.

Risk management for the entire group is monitored through the Group Risk and Compliance Committee and other bodies, and improvements and preventative measures are implemented.

Each group company formulates risk management policies and basic plans under its own promotion system, and compiles information on the risk management status of the entire company.

Risk and Compliance Structure

- The image can be scrolled left and right

Important Risks

The major risks that Toyo Seikan Group recognizes as having the potential to have a significant impact on its business performance, finances, and management are as follows:

- Risk of natural disasters, infectious diseases, and accidents

Business continuity from natural disasters / infectious diseases / occupational accidents and health and safety - Compliance Risk

Compliance/Human rights violations and discrimination - Business and management risks

Changes in economic conditions / Fluctuations in production costs / Procurement of raw materials / Intensifying price competition / Research and development / Investment and financing (corporate acquisitions, capital participation, capital investment, etc.) / Promotion of digitalization / Credit risk of business partners / Securing and developing human resources / Litigation risk / Overseas business - Information Security Risk

Leakage of personal information/Leakage of trade secrets and confidential information/Cyber attacks and virus intrusions - Financial and accounting risks

Funding/Changes in accounting standards and tax systems, etc. - Manufacturing and quality risks

- Environmental Risks

- Country Risk

For details regarding significant risks, please refer to the Annual Securities Report for the fiscal year ending March 31, 2025 (PDF, pages 43-48).

Strengthening Risk and Crisis Management Systems

Toyo Seikan Group In order to respond to risks and crisis events surrounding the Group and prevent the occurrence of risks that may affect ongoing business activities, the Company has established the Risk and Crisis Management Committee as an organization to strengthen the risk and crisis management system, the Group Risk and Compliance Committee to oversee risk and crisis management and compliance of the Group across the board, and the Risk and Crisis Management Control Office as the secretariat of the Risk and Crisis Management Control Office. The Risk and Crisis Management Office has been established as the secretariat of the Risk and Crisis Management Committee and the Group Risk and Compliance Committee, which oversees risk and crisis management and compliance across the Group. Both committees share information on social trends and other risk-related issues, check the status of responses to major risks, and implement improvements and preventive measures. In addition, in order to stabilize the management foundation, the Company and its group companies formulate crisis management regulations and crisis response manuals under their respective management systems, compile the status of risk management, and report to the Committee.

In addition, in the event of a crisis, the Company and its group companies have formulated a business continuity plan ("BCP") to minimize damage and restore and continue business activities as quickly as possible, placing the highest priority on respect for human life, and are promoting the strengthening of risk management systems.

Initiatives for Fiscal 2024 and Activities for Fiscal 2025

As part of our risk management efforts in fiscal 2024, we assessed the current status of each group company regarding the Group's major risks and confirmed the status of their BCP formulation.

Specifically, the likelihood and impact of these risks on each company's business were analyzed, and the extent to which they were addressed was evaluated. Eleven Group companies participated in this process. Through these risk analyses and evaluations, each Group company clarified the priorities for risk responses and is steadily advancing risk management based on a risk-based approach.

In fiscal 2025, we will focus on the following five key activities for the Group's risk and crisis management activities, and will undertake various activities.

- Disseminating risk-related information and raising awareness among group companies

- Confirmation of the status of risk management activities at each group company

- Education and training tailored to risk trends

- Formulating and disseminating risk management policies

- Publicizing and properly operating the internal reporting system (consultation desk)

Initiatives of Major Operating Companies

Initiatives for fiscal 2024

BCP implementation

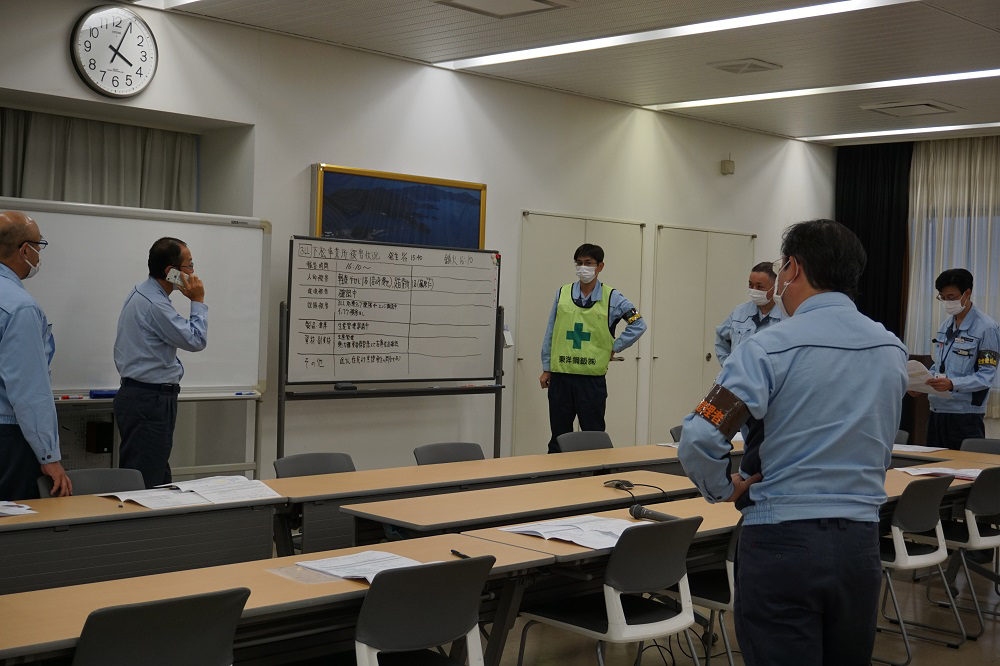

Toyo SeikanIn March, we conducted a BCP drill with the participation of all our business locations, simulating a situation in which flooding occurs due to torrential rain caused by a linear rain band associated with a typhoon, and multiple factories are affected simultaneously. All business locations and each department at the head office received instructions from the online headquarters, and confirmed the flow of reporting damage status and decision-making for recovery based on the formulated BCP, using the disaster prevention portal site "BCPortal."

Toyo KohanIn November, we conducted training based on the scenario of a fire occurring at the electronic materials factory at the Kudamatsu Plant. The training was divided into an initial response BCP for the initial response to the fire and a business continuity BCP, which covers everything from reporting the damage situation to taking measures and recovery.

Mebius PackagingWe partially revised our disaster response manual and established new basic action guidelines, and conducted BCP training in February and March, assuming wind and flood damage.

Lecture by industrial physician on "Current status and future trends of chemical substance management"

On March 12th, TOMATEC's Kyushu Factory held a lecture by an industrial physician entitled "Current Status and Future Trends of Chemical Substance Management." The lecture covered topics for promoting daily safety and health activities, such as the proper way to wear protective work gloves, conducting risk assessments using the risk assessment tool "CREATE-SIMPLE" recommended by the Ministry of Health, Labor and Welfare, and inspecting local exhaust ventilation systems. We will continue to take various measures to more widely publicize and expand our "chemical substance management" efforts.