Quality Assurance System

Basic Perspective

Toyo Seikan Group is committed to providing safe and useful products, systems, and services to society, and to ensuring customer peace of mind and satisfaction, through tireless quality assurance activities, and is committed to improving quality so that it can contribute to maximizing value for all stakeholders.

- We will make fair and prompt decisions and take action from the perspective of society and our customers.

- We will adhere to quality compliance through sincere communication with business partners, employees, and all stakeholders.

- We will promote the use of digital and automation technologies and work to improve the reliability of quality assurance.

- We comply with all applicable laws and safety standards and provide products that comply with them.

- We will work to continuously improve our quality assurance system to adapt to changes in the environment.

Quality assurance and product safety initiatives

Building a management system

To ensure stable quality and continuous improvement in products, systems, and services, each operating company of Toyo Seikan Group has established a quality management system (ISO9001). In addition, each company that manufactures and sells food containers has established a food safety management system (FSSC22000), working to provide safer products and improve reliability in the food chain.

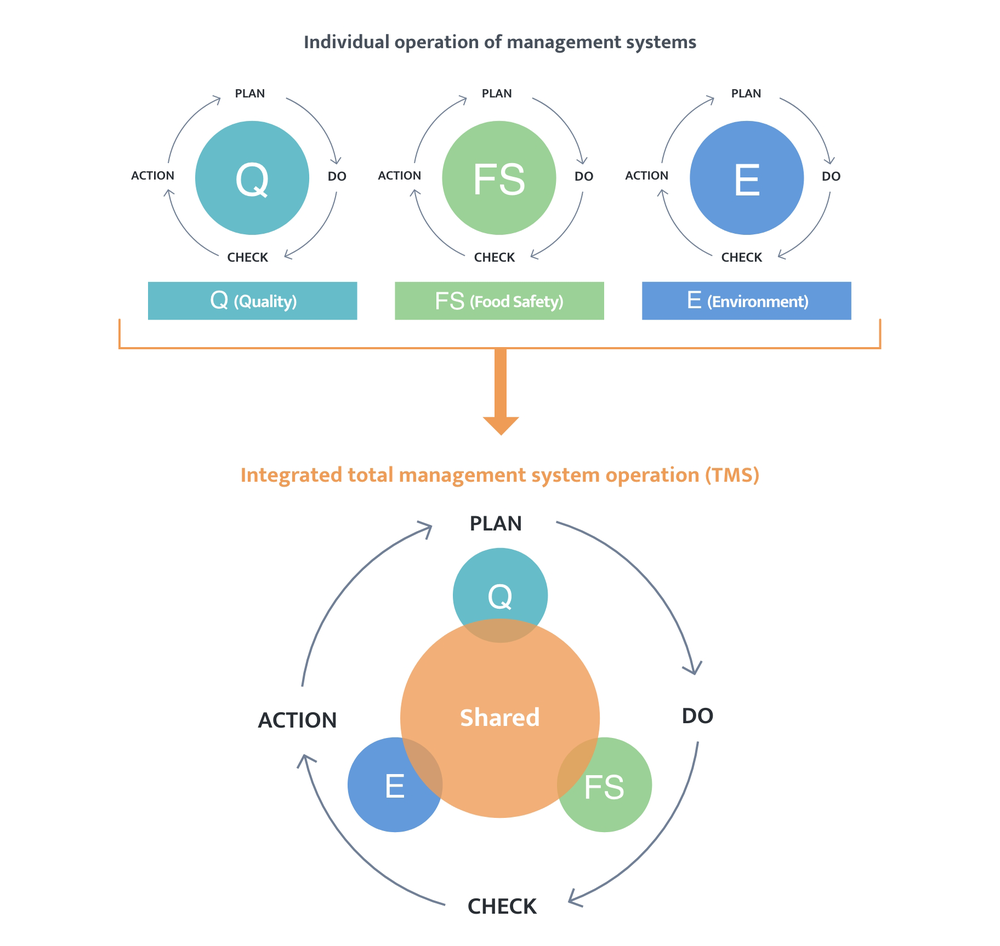

In particular, Toyo Seikan, TOYO GLASS, and Mebius Packaging have established an "Integrated Management System (TMS)" that integrates the operation of three management systems: quality, food safety, and the environment (ISO14001). By integrating the management systems, we have eliminated redundant operations, broadened our perspective from partial optimization to overall optimization, and are promoting manufacturing that is trusted by customers by using a "living system" that combines the management system with business activities.

- The image can be scrolled left and right

quality education

Within Toyo Seikan Group, each operating company provides quality education tailored to the characteristics of its business and products.In addition, by engaging in various improvement activities using quality control methods, we strive to maintain and improve employee sensitivity to quality.

Response to quality risks shared across the Group

Toyo Seikan Group works together with group companies to share and address issues related to measures to address various quality risks, such as serious product defects, quality fraud, intentional product contamination, violations of laws and contracts, product guarantees in the event of major disasters, and crisis responses to quality emergencies.The Group's direction is aligned and activities are carried out at the Group Quality Meeting, which is attended by quality assurance officers and quality assurance department managers from the holding company and each operating company.

In particular, the root cause of problems that significantly damage the trust of stakeholders is closely related to employees' quality awareness. Therefore, we are working across the Group to maintain and improve quality awareness by objectively visualizing this through quality awareness surveys.