Case studies

Three key initiatives

Realizing the autonomy of production systems and the efficiency of business processes

Transforming into a smart factory/office

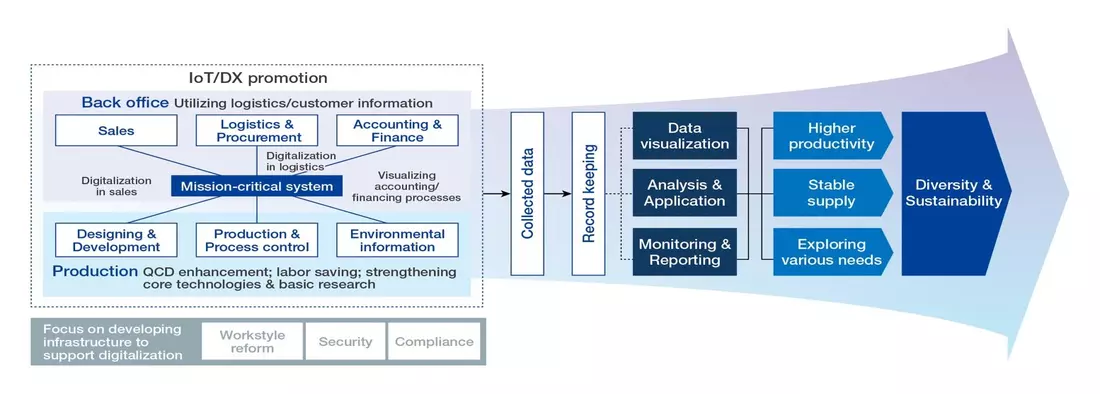

To advance information technology and digital transformation within our group, it is necessary to collect and enrich information, integrate and store it in an easy-to-use format, and then make the right decisions and take correct action based on analysis. Currently, our group is gradually promoting "data visualization, analysis, and measures" at production sites, focusing on core business operations. At the same time, we are also further enhancing in-house education to reflect data analysis in manufacturing and business.

Promoting data sharing across the entire supply chain

Sharing a wide range of data across the entire supply chain will enable unprecedented services. In preparation for this, we are working to collect real-time data on product shipments and deliveries, as well as environmental data such as GHG reduction and water resource conservation.

Application and development to expand business areas

Because the products and services resulting from solving problems within the Group may also lead to solving problems outside the company, we are promoting development aimed at expanding and creating new business fields. In addition, by utilizing digital technology, we aim to accelerate marketing and technological development in new fields and create new value based on the strengths the Group has cultivated, such as "material development," "molding processing," and "engineering."

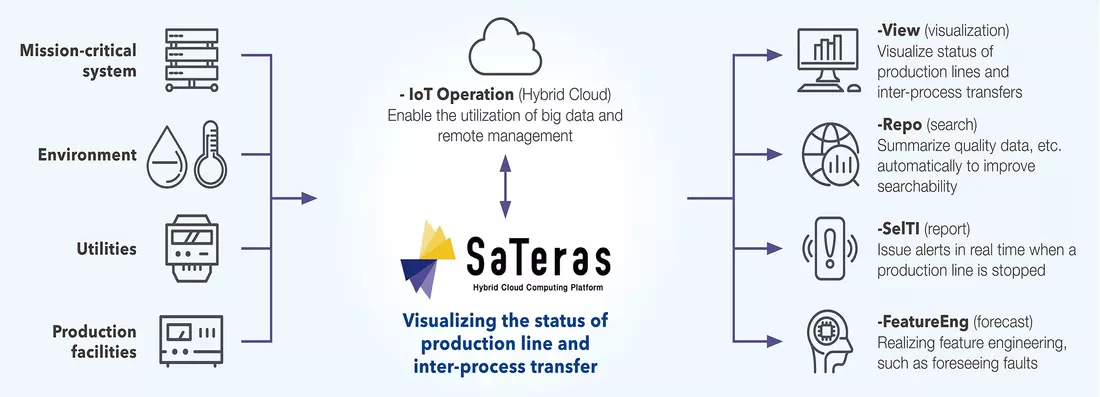

"SaTeras" is an IoT solution that promotes digitalization in production sites and leads to improvements.

We are developing a proprietary data collection package called "SaTeras" that enables the centralized management of manufacturing and production-related data. SaTeras makes it possible to collect and visualize production-related data, such as the operating conditions and measurement values of manufacturing equipment, all at once. Furthermore, by analyzing the accumulated data, it is possible to build an autonomous system that prevents process defects and maintains high quality.

Currently, the initial implementation has been completed at six domestic aluminum can manufacturing bases, and trial deployment is being carried out at key group companies. SaTeras can be combined with the functions and services needed at any given time, and its flexible design allows for the expansion of resources, helping to resolve issues faced by manufacturing sites, such as further improving production efficiency and transferring skills, leading to the creation of new value.

Simply integrates all data from manufacturing sites and provides an environment where users can utilize it.

- Consistent data utilization, maintenance-free design, retrofitting, remote management

- Digitalization of manufacturing know-how using data analysis technology

- The image can be scrolled left and right

"Fact" is a core system that improves back-office efficiency and optimizes strategies

Our main group companies in the domestic Packaging Business are currently upgrading to our proprietary core system, "Fact." While the basic components are unified, the system is designed to be flexible enough to accommodate customization by each company, and aims to promote paperless operations, automation and efficiency of operations, and telecommuting.

We have now completed the initial implementation at Toyo Seikan Co., Ltd. and Mebius Packaging Co., Ltd., and will gradually roll it out to our main domestic group companies. At the same time, we will proceed with development aimed at integrating accounting systems as a subsystem, aiming to improve the efficiency of deposits and withdrawals and settlement of accounts. Furthermore, we will promote collaboration with logistics and production management systems, aiming to optimize sales strategies, production plans, and logistics procurement.

- The image can be scrolled left and right

Overview of the Group's digital utilization

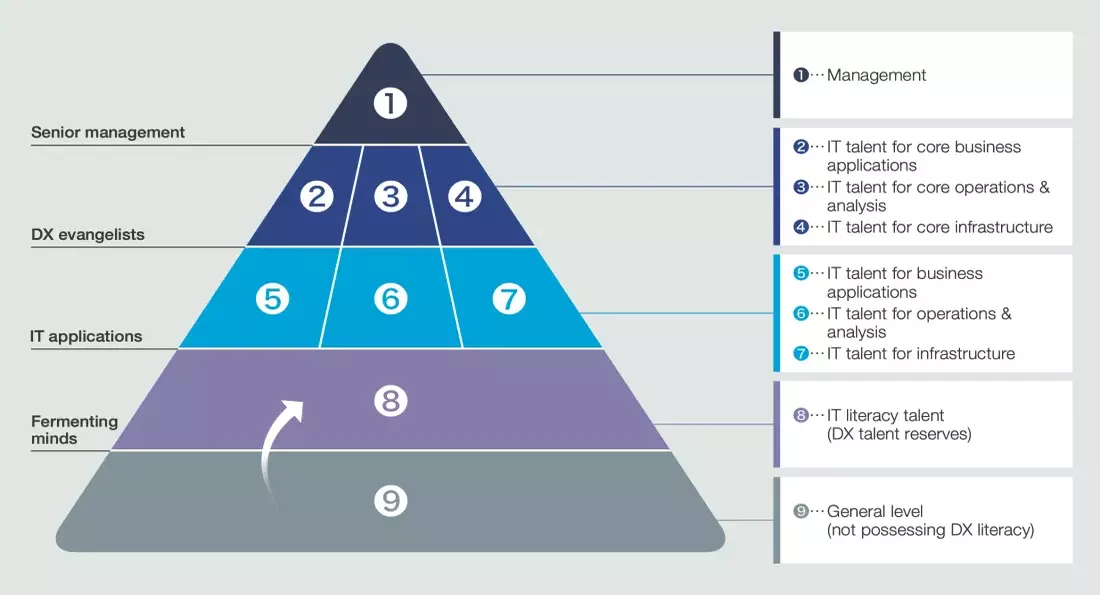

Towards digital talent development

To advance data utilization, it is important to develop human resources who can use data and digital technology to solve management issues, expand business areas, and improve operational efficiency. Specifically, we need people who can analyze data collected from business systems and equipment to solve issues within their own company or department, and who can use business automation tools such as RPA * to improve work efficiency.

Toyo Seikan Group Holdings has therefore taken the lead among its group companies by starting DX literacy education for all employees in 2023. It plans to roll out similar initiatives to its group companies in the future.

- An abbreviation of "Robotic Process Automation," meaning "automation of business processes using robots."

Human Resources Pyramid for Realizing Group Digital Vision 2030

- The image can be scrolled left and right

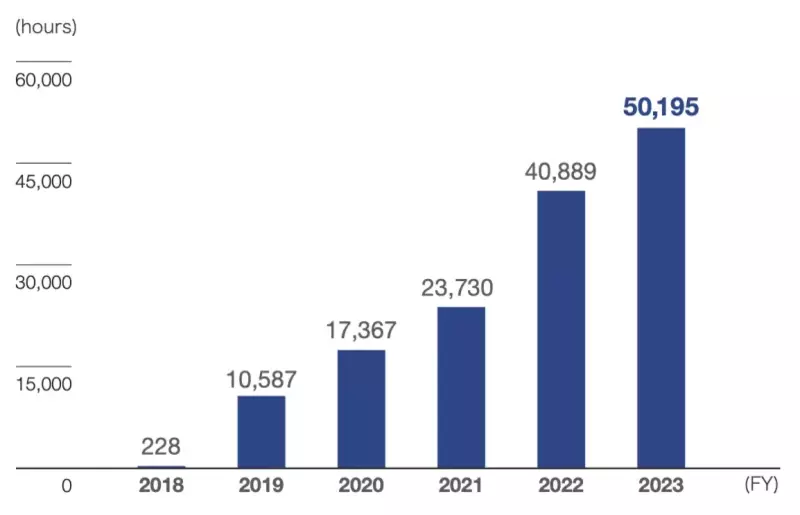

RPA utilization status

Toyo Seikan Group is promoting the use of RPA to increase productivity and improve operations. By automating PC tasks, employees can focus on more advanced tasks. Over the six years from 2018 to 2023, RPA will be used in over 400 tasks, resulting in a cumulative reduction of approximately 50,000 man-hours. Until now, the target areas have mainly been core systems such as SCM and sales, and administrative systems such as human resources and accounting, but the use has been expanded to include general affairs and purchasing, and further expansion to research and development departments is being considered.

Work hours reduced through RPA (cumulative total)