Technology and Development

Based on the technical know-how of material development, molding and processing, and engineering that Toyo Seikan Group has cultivated over the years, we are actively working to develop innovative technologies and contribute to the environment. By continuing to provide environmentally friendly products through technology and development, we will meet the expectations of our customers and contribute to the sustainable development of society as a whole.

Message from the Executive Officer

Takuji Nakamura

President and Representative Director

Chairman of Group Risk and Compliance Committee

Chief Technology Officer

We will achieve sustainable growth by integrating technology, intellectual property, and business strategy to solve social issues one by one.

Strengths and challenges in technological development

Toyo Seikan Group 's strength lies in its manufacturing technology, which has been cultivated over many years, primarily in packaging containers. We continue to develop optimal shapes and functions for a wide range of uses, including beverages, food, and daily necessities, using a variety of materials, including metal, plastic, paper, and glass, to meet customer needs. Even amidst fierce cost competition, we have continued to develop high-quality, high-added-value technologies without downsizing our development department.Furthermore, Toyo Seikan Group not only has technology related to the containers themselves, but also has a variety of elemental technologies, such as basic research on materials, evaluation of contents, and design of production equipment, and we also have the human resources to realize these.It is important to be more aware of and utilize the value of intangible assets such as knowledge and know-how, not just technology related to visible things like products and equipment, and I feel that this is also a challenge for Toyo Seikan Group.

Demand for packaging containers has increased alongside the growth of the Japanese economy, and Toyo Seikan Group has continued to grow, but the business environment is undergoing major changes. Our strengths of mass production and technological development aimed at consistent quality alone are no longer sufficient to address the sustainability needs of today's society or solve environmental challenges. Effective resource utilization, particularly through the concepts of reduce, reuse, and recycle, can sometimes conflict with Toyo Seikan Group 's business model, which mass-produces one-way containers. For example, developing a new material that uses less resin can be meaningless if it cannot be recycled, or establishing a material recycling process is meaningless if the collection process is not also established. This means that technological development must take into account the entire recycling process, starting from the product design stage.

In order to develop new businesses while responding to diversifying social issues and needs, it is important to develop technologies and businesses by leveraging not only existing packaging container technologies and businesses, but also the strengths of know-how and intangible assets that have been accumulated over the years.

Aiming for sustainability in both environmental contribution and corporate growth

There are currently many social issues in the world. Our management will provide support for each social issue in the packaging field by providing the organizational structure and systems necessary to resolve them, making full use of the technology we have cultivated and our intellectual property strategy that leverages intangible assets. By integrating our technology strategy, intellectual property strategy, and management strategy, we hope to become a corporate group that continues to innovate as it has in the past. We believe that this is the shortcut to realizing a sustainable future not only for Toyo Seikan Group, but also for the global environment.Technology Development System

Within Toyo Seikan Group, technological development is carried out in collaboration with the development departments of each operating company, centered around the development functional departments of Toyo Seikan Group Holdings, including the Research Institute, which is responsible for basic research and development.

Initiatives by each company

■ Three companies launch joint project to transform CO₂ into a resource

Low-cost, highly efficient CO₂ separation and capture technologies are attracting attention as we move towards a carbon-neutral society by 2050. Toyo Seikan Group Holdings has partnered with JCCL Ltd. (hereinafter "JCCL") and Mitsui Bussan Plastics Co., Ltd. (hereinafter "Mitsui Bussan Plastics") to launch a joint project aimed at the early implementation of JCCL's CO₂ separation and capture technology in society.

JCCL possesses two proprietary technologies that can efficiently separate and capture low-concentration CO₂ from exhaust gases after combustion of heavy oil and city gas, etc., and from the atmosphere using low energy. In addition to reducing capture costs by effectively utilizing unused waste heat, this technology also has the advantage of avoiding the risk of environmental pollution caused by the volatilization and leakage of amines by using a polymer gel absorbent called "amine-containing gel."

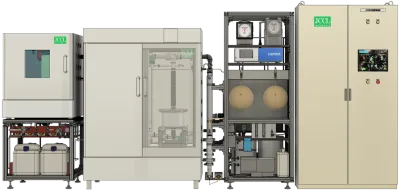

Small CO₂ recovery unit (VPSA1)

Each company's role in this initiative

- The table can be scrolled left and right

| company | role |

|---|---|

| JCCL (Kyushu University startup) |

We are responsible for improving technologies and equipment and building a patent network with the aim of implementing energy-saving CO2 separation and capture equipment in society. |

| Toyo Seikan Group | Utilizing the technical capabilities we have cultivated in the manufacture of packaging containers, we will be responsible for standardizing and scaling up the equipment, as well as manufacturing, and will support the process towards practical application. |

| Mitsui Bussan Plastics | Leveraging our global sales network and marketing capabilities, we are promoting the international standardization of the CO₂ separation and capture process. |

Each company's role in this initiative

Toyo Kohan Kudamatsu Plant has been conducting demonstration experiments using a small-scale CO₂ capture unit (VPSA1) since fiscal 2025. These demonstration experiments will evaluate the durability of various equipment materials, optimize facilities to meet on-site needs, and develop technologies for mass production.

Based on these results, we plan to implement a small-scale device with a CO₂ capture capacity of 30 kg/day in fiscal 2025, and a container-type device with a capacity of 300-500 kg/day in fiscal 2026. We are also currently developing an energy-saving Direct Air Capture (DAC) system, aiming to begin demonstration testing in fiscal 2025. In the future, by combining JCCL's two technologies, we aim to capture low-concentration CO₂ in the atmosphere using DAC at low cost and with high efficiency, at a high purity of 97-99%.

Furthermore, we have begun working with other partner companies to utilize the captured CO₂.

Going forward, we will continue to strengthen our collaboration toward the early implementation of energy-saving CO₂ separation and capture processes and their utilization models in society, and contribute to the realization of a carbon-neutral society by 2050.

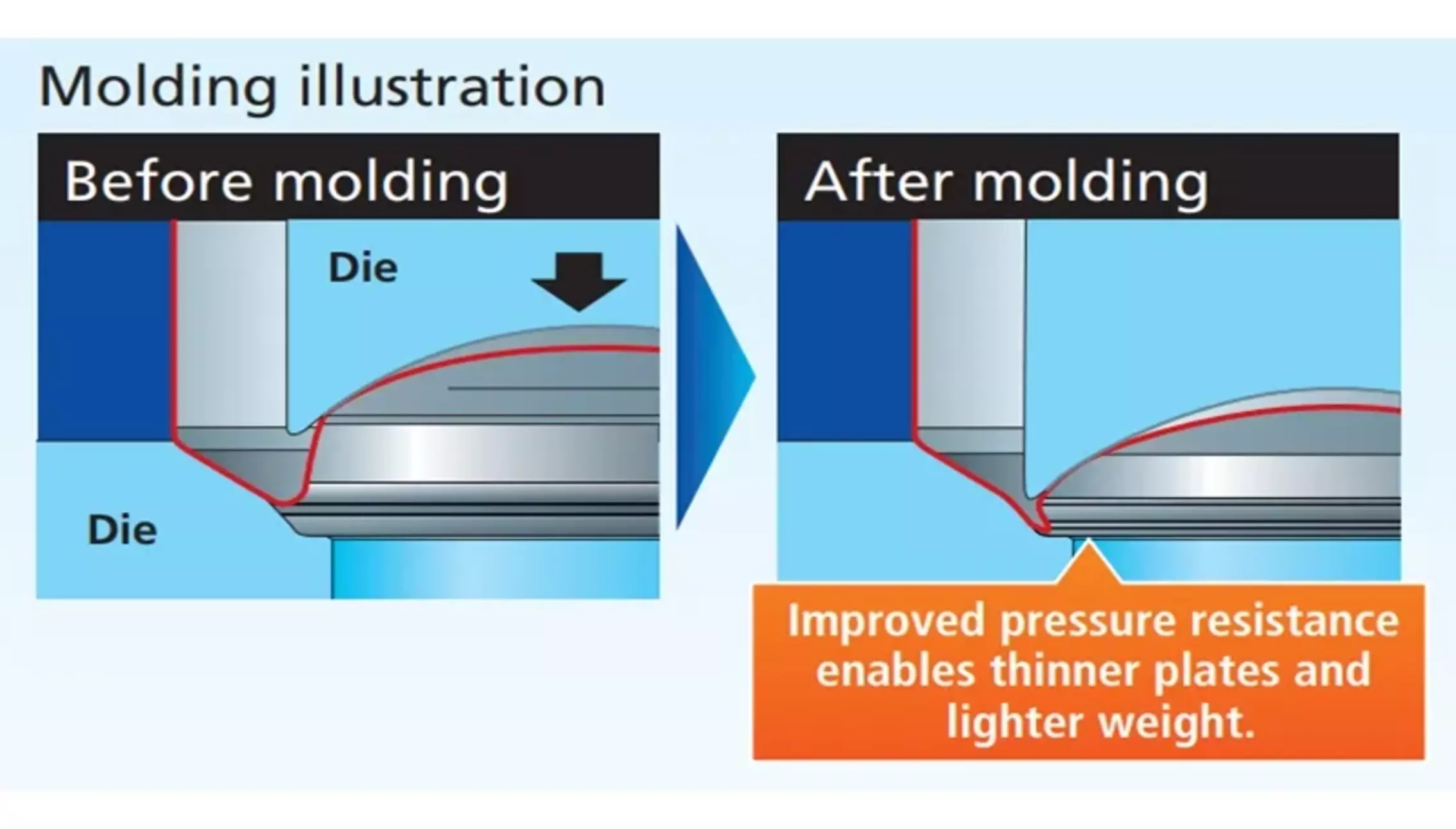

■ Technological innovation to reduce the weight of aluminum cans and their environmental impact

Toyo Seikan introduced CBR (Compression Bottom Reform), an innovative Compression Bottom Reform that renovates and strengthens the bottom of aluminum beverage cans to reduce weight. This technology is expected to significantly reduce the weight of aluminum beverage cans and further reduce greenhouse gas (GHG) emissions.

Image of can bottom forming using CBR

Expectations for a 40,000 t reduction in greenhouse gas emissions per year

By using CBR, the 350ml can was reduced from 11.7g to 10.2g, and the 500ml can was reduced from 15.0g to 13.0g, a reduction of 1.5g and 2.0g, respectively. As a result, GHG emissions per can were reduced by approximately 9% for both the 350ml and 500ml cans compared to the current cans. Similarly, the 190ml can was reduced from 7.0g to 6.1g, a reduction of 0.9g, resulting in an approximately 8% reduction in GHG emissions per can. Furthermore, if CBR were adopted for all aluminum beverage cans for which CBR is applicable, GHG emissions are expected to be reduced by approximately 40,000 tons * per year.

- Calculations based on Toyo Seikan production results for current-spec aluminum beverage cans in fiscal 2022 and the GHG reduction per can using CBR

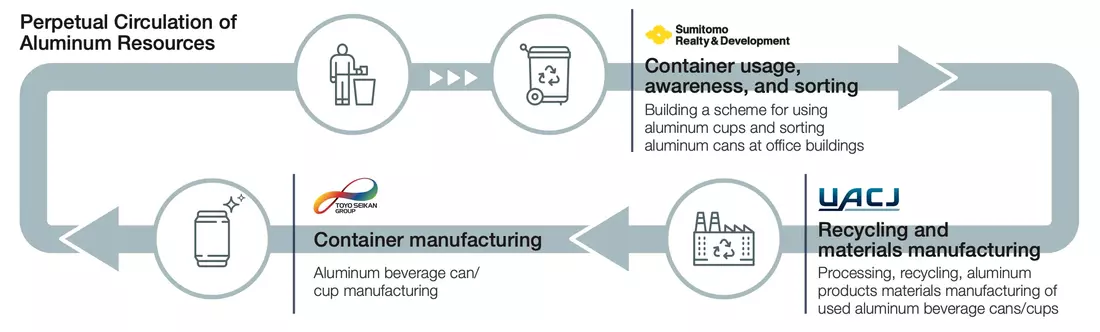

■ Building a supply chain for horizontal aluminum can recycling to realize a recycling-oriented society

Toyo Seikan Group, in collaboration with Sumitomo Realty & Development Co., Ltd. and UACJ Corporation, has established a supply chain for "horizontal aluminum can recycling." This initiative involves recycling used aluminum cans and reusing them as aluminum cans and aluminum beverage cups called "Lumisus®." After a test run in 2023, full-scale operation began in April 2024.

Under this recycling scheme, aluminum cans discarded from Sumitomo Realty & Development Co., Ltd.'s office buildings undergo a recycling process and are delivered to UACJ Corporation's factories as recycled raw materials, where they are processed into aluminum plate products. The Group then produces new aluminum cans and Lumisus, which are then recycled. This horizontal recycling will reduce dependence on imports of new aluminum ore, and will significantly contribute to realizing domestic resource circulation and reducing GHG emissions.

*The image can be scrolled left and right.