Open Up!Products and Services

aluminum Toyo ULtimate Can (aTULC) Compact Canmaking Line+Ultimate-lightweight cans

Toyo Seikan Co., Ltd.

aTULC Compact Canmaking Line is an integrated system that spans the entire value chain from can manufacturing to filling, eliminating the need for can transportation. This results in a reduction of transportation costs and environmental impact compared to traditional can manufacturing systems.

By combining Compression Bottom Reform (CBR®) and aTULC's superior puncture strength with the aTULC compact line, we will strive to achieve the realization of Ultimate-lightweight cans.

In the conventional metal can system, cans are manufactured at canning plants and then transported as empty containers to beverage factories. There, they are filled with beverage and then shipped to stores nationwide. It was difficult to achieve container manufacturing and filling consistently at beverage factories, which would have reduced transportation costs, decreased truck emissions, and minimized environmental impact.

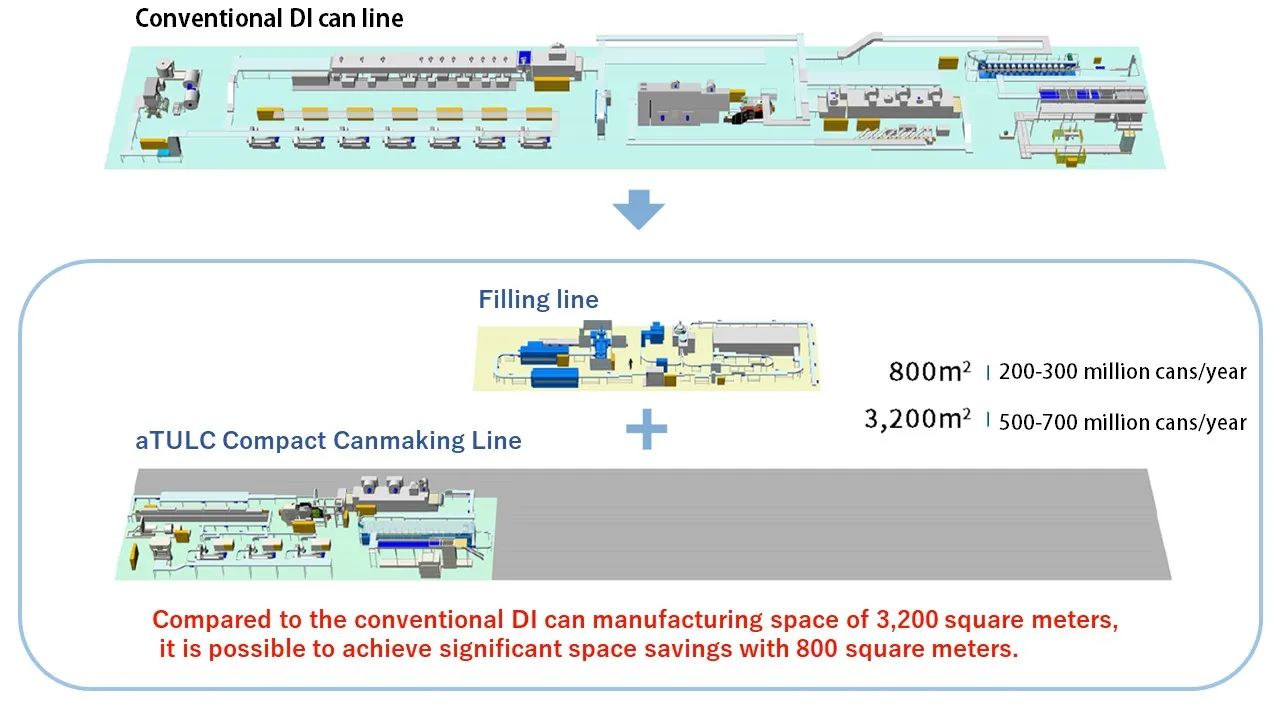

The newly developed aTULC Compact Canmaking Line combines the advantages of a "metal container with a high recycling rate," "aTULC with excellent productivity and environmental conservation," and "PET bottles with easy operation." It establishes a production system of "space-saving, short construction period, and low cost," capable of manufacturing 200-300 million cans annually at about half the production speed of traditional large-scale lines.

By enabling consistent production from can manufacturing to filling, the need for can transportation is eliminated. This allows for a reassessment of the distribution strength characteristics associated with can lightweighting, making it possible to fill and sell the Ultimate-lightweight cans developed by Toyo Seikan Co., Ltd.

This system makes it easier to accommodate the needs of small-scale beverage can manufacturer and contributes to a circular economy, as well as reducing greenhouse gas emissions during manufacturing and transportation.

Thanks to the Compression Bottom Reform (CBR®), it has become possible to achieve significant weight reduction in aluminum cans. CBR® offers a much higher strength improvement compared to conventional can bottom reinforcement techniques, allowing for a substantial reduction in the amount of material used in the can bottom section. By combining the advantage of aTULC's puncture strength in the can body with the thinning of the can body, and integrating the value chain from can manufacturing to filling through the introduction of aTULC Compact Canmaking Line, we are challenging ourselves to achieve Ultimate-lightweight cans.