Open Up!Products and Services

Polyolefin Bottle that Uses Recycled Materials

Mebius Packaging Co., Ltd.

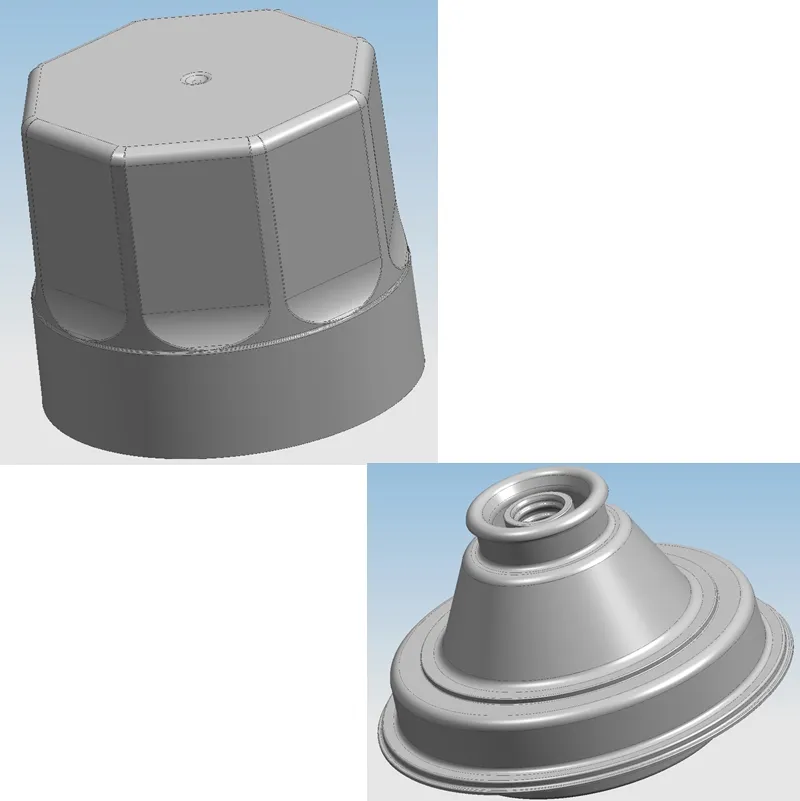

A polyolefin bottle that uses recycled materials to reduce greenhouse gas (GHG) emissions

•Lower GHG emissions during both material procurement and product disposal (such as incineration)

•By adopting multi-layer molding that sandwiches recycled material, the bottle can be used for a wide variety of non-food applications, including for daily commodities

Conventional polyolefin bottles are manufactured using petroleum-derived raw materials, which result in high GHG emissions during both material procurement and product disposal (such as incineration).

To address this issue, we have commercialized daily-use products using bottles that contain approximately 60% recycled polyolefin material.As a result, we were able to reduce GHG emissions during procurement, disposal, and recycling processes by approximately 30%*.

* Reduction calculated by Toyo Seikan Group Holdings

Itabashi: The opportunity came when Lion Corporation consulted us about a model update. For this update, Lion requested a more environmentally conscious solution, that would include changing the bottle’s shape, reducing its weight, and using recycled polyolefin material. This set our direction for developing a suitable container.

Itabashi: At the time of Lion's request in 2021, developing containers using recycled polyolefin material was a new challenge for our company.

Initially, we struggled to maintain quality because of instability in mass and wall thickness during molding. However, our Development Technology Department did not give up and persistently investigated the causes of this instability. Eventually, thanks to the suggestions and cooperation from Lion and a recycled material manufacturer, we were able to proceed with the development and gradually improve the quality.

Tanaka: Conventional petroleum-derived raw materials procured from resin manufacturers have minimal variation in physical properties, allowing for stable molding. In contrast, recycled material, made from crushed and washed post-consumer plastics, can vary greatly, making consistent molding extremely difficult.

Itabashi: Due to their characteristics, containers that use recycled materials naturally raise concerns about appearance or deformation during transport due to insufficient strength. However, even after a year on the market, there have been no particular problems, and the bottles are being used the same as those made from petroleum-based materials. We believe this serves as an excellent example to society that bottle molding using recycled polyolefin materials is possible.

Tanaka: This product contains about 60% recycled material, which is a very high content even compared with similar products on the market. Together with Lion, we will continue working to further increase the proportion of recycled materials in our products and expand to other items, aiming to grow the total volume of recycled materials. Rather than compromising because it’s "just recycled material," we will keep challenging ourselves to find solutions to what we want to achieve.

It’s a wonderful initiative to enable the use of recycled material in products where it was previously difficult.

It must have been challenging to balance requirements such as sealing and product protection, but I hope you will continue toward achieving 100% recycled material use. Also, considering the vast number of plastic bottles used globally, I hope your efforts will expand to many areas and fields.