Achieving a Society Coexisting with Nature

Water Resource Initiatives

Facility risk management

Toyo Seikan Group strives to manage risks in accordance with each company's environmental management system with the aim of preventing accidents that could adversely affect the quality of public water bodies (rivers, oceans, etc.) and groundwater, such as oil spills from factories and abnormal wastewater discharges due to faulty wastewater treatment. For facilities with a particularly high risk of environmental accidents, we regularly monitor deterioration and damage to equipment piping, tanks, valves, etc., based on the Toyo Seikan Group Facilities Environmental Risk Management Guidelines established in fiscal 2021. Going forward, we will continue to make improvements by implementing the PDCA cycle based on each company's environmental management system.

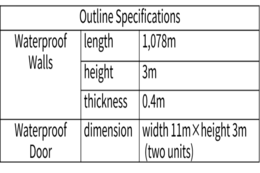

Installation of waterproof walls and doors at Toyo Seikan Co., Ltd. Hiroshima Factory

The plant suffered flooding damage during the heavy rains in Western Japan in 2018. To protect the lives of employees and the plant in the event of a similar natural disaster in the future, a 3m-high flood wall and watertight door were installed at the boundary of the site in June 2020. This prevents flooding onto the site and allows the plant to be used as an evacuation site for nearby residents.

waterproof wall

Waterproof door wall

Evacuation stairs for local residents

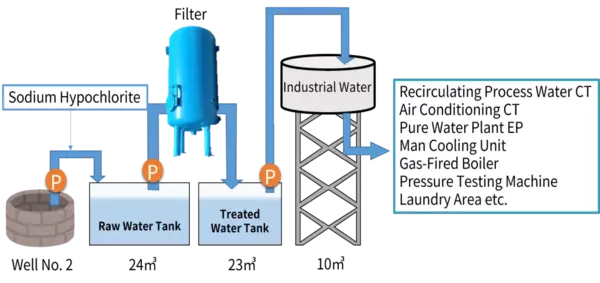

TOYO GLASS CO., LTD. Chiba Factory Rainwater Collection System

At TOYO GLASS CO., LTD. 's Chiba Factory, rainwater is collected from the roof of the box-making factory and stored in a raw water tank, making effective use of it. Approximately 2,606 m3 of rainwater is collected annually.

Industrial water flow diagram

Rainwater collection pipe installation

Initiatives to Conserve Biodiversity

Initiatives to address the problem of marine plastic waste

Activities through the Clean Ocean Materials Alliance

The problem of marine plastic waste is a new global challenge. To solve this problem, we need to promote more sustainable use of plastic products, the development and introduction of alternative materials, and accelerate innovation through public-private collaboration. Against this backdrop, the Clean Ocean Material Alliance (CLOMA), made up of a wide range of businesses that make up the supply chain, was established in January 2019. As of April 2023, the alliance will have 486 participating companies and organizations, representing a wide range of industries within the supply chain. Toyo Seikan Group Holdings has been involved in the alliance since its establishment preparation stage as a lead company, and is active as a key member of the Promotion Subcommittee, which is responsible for sharing information and promoting collaboration with stakeholders across industries.

Additionally, Toyo Seikan Group is participating in all five working group activities that will implement the new action plan formulated in 2020, and is taking part in planning the demonstration tests that will be carried out there. Through these activities at CLOMA, Toyo Seikan Group will continue to contribute to solving the problem of marine plastic waste.

Thorough measures to prevent resin pellet leakage

If resin pellets (a few millimeters in size), which are the raw material for plastic products, leak outside of factory premises, they will become marine plastic waste. We have previously implemented measures such as installing wire mesh in rainwater gutters to prevent resin pellets spilled onto roads from leaking outside of factory premises, but in 2019 we formulated the Toyo Seikan Group Resin Pellet Leakage Prevention Guidelines to thoroughly manage the situation with the aim of achieving zero leakage. These guidelines are implemented within each company's environmental management system, including "identifying potential leakage locations and considering and implementing prevention measures," "daily management," and "audits."

Example of pellet collection screen installation (rainwater tank)

Development of environmental DNA chips for investigating invasive fish species in dams

Through joint research with Yamaguchi University and Nippon Koei Co., Ltd., it has been discovered that the DNA chip gene analysis system developed by Toyo Kohan for use in the medical field can be applied to the environmental field.

Previously, surveys of invasive fish species living in dam reservoirs required investigators to dive into the dam or capture them with nets, which was costly and time-consuming. However, by using the newly developed environmental DNA chip to collect and analyze 1 liter of water from a dam reservoir, it is possible to easily determine the types of invasive fish present. Invasive species are a general term for biological species that do not naturally inhabit an area, and their introduction is known to cause serious damage to ecosystems.

The water in the dam reservoir contains trace amounts of DNA found in the droppings and scales of invasive fish, and this environmental DNA chip can detect even such trace amounts of DNA.

The results of this research were published in the international academic journal Landscape and Ecological Engineering in June 2022.

Toyo Kohan will continue to expand its range of medical DNA chips, but will also contribute to the environmental field, which is linked to the SDGs, by preserving the environment of dam reservoirs and rivers.

Creating a blue carbon ecosystem

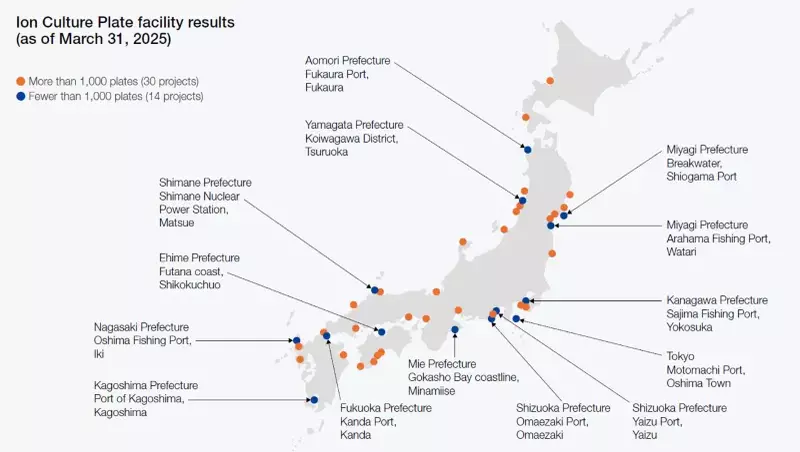

Wakame seaweed bed development project using Ion Culture Plates "Blue Carbon Ecosystem Creation Project in the Sea Area Surrounding the Osaka Expo Site"

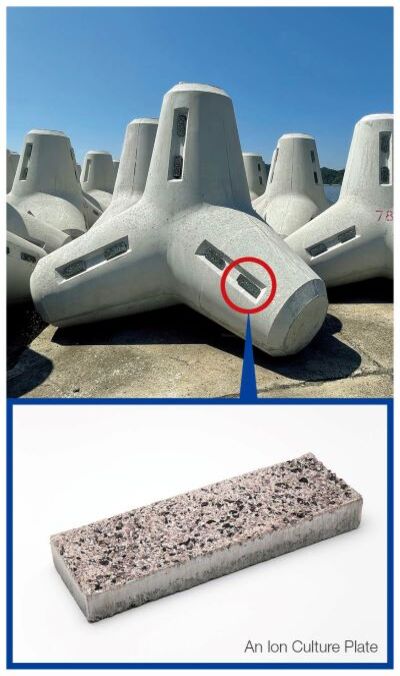

Ion Culture, jointly developed by TOYO GLASS Ltd. and Fudo Tetra Co., Ltd., is a glass product whose composition has been adjusted so that components such as ferrous iron, silica, and phosphate ions, which promote the growth of marine plants, slowly dissolve into water.

The "Ion Culture Plate" is a mortar plate with Ion Culture on its surface, which is used to grow large seaweed along the ocean coast and create fishing grounds. By attaching it to the surface of tetrapods in ports and on the coast, it promotes the growth of seaweed, contributing to the creation of a blue carbon ecosystem.

This project aims to contribute to the creation of a blue carbon ecosystem in the waters surrounding the Osaka-Kansai Expo site by utilizing the track record and experience of both companies, Ion Culture and Tetrapod, in creating seaweed beds.

Ion Culture plates that dissolve iron, silicon, and other nutrients necessary for seaweed growth are attached to the tetrapods to promote growth, aiming to quickly create a seaweed bed. In addition, spore bags containing wakame seed threads and mother algae in natural mesh bags are attached around Ion Culture plates to serve as a source of wakame spores.

Installation will begin in December 2024, and after installation, surveys of coverage (the percentage of the block surface covered by growing seaweed) will be conducted twice a year through underwater visual observation.

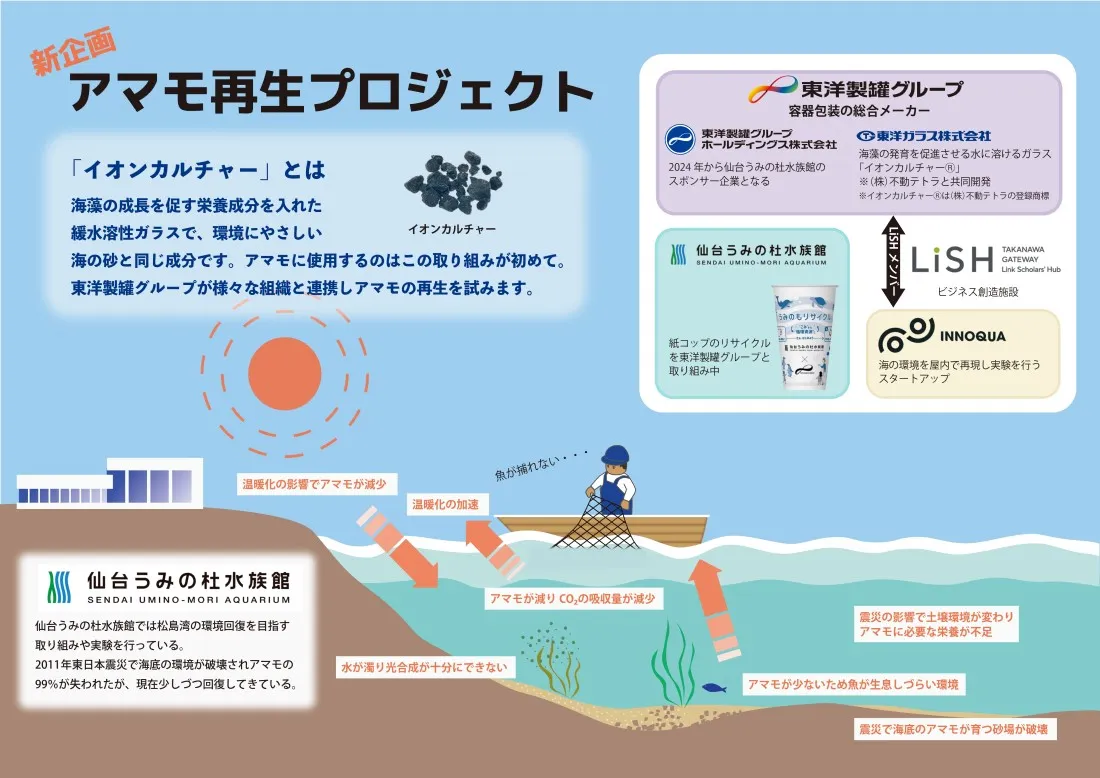

Launch of eelgrass restoration project to restore blue carbon ecosystems and conserve biodiversity

Toyo Seikan Group launched a project to restore eelgrass beds in August 2025 to restore "blue carbon," which has a CO₂ absorbing effect, and to conserve biodiversity. This project utilizes "Ion Culture," an algae propagation material jointly developed by TOYO GLASS and Fudo Tetra Co., Ltd., to observe and exhibit eelgrass growth at the Sendai Uminomori Aquarium, and will also collaborate with Inoka Co., Ltd. to scientifically verify its growth promotion effects at a laboratory within Takanawa Gateway City. Going forward, the Group will work with fisheries cooperatives and local governments in Miyagi Prefecture to introduce the product to coastal areas and restore eelgrass beds, aiming for nationwide expansion and contributing to the creation of a decarbonized society and a society in harmony with nature.

[September 1, 2025 Press Release] Launch of eelgrass restoration project to restore blue carbon ecosystems and conserve biodiversity nationwide - Sendai Umino-Mori Aquarium begins research and verification in collaboration with environmental transport venture Inoka -

Invested in Seadling, a company developing sustainable seaweed farming and functional ingredients in Southeast Asia

Toyo Seikan Group Holdings As part of the "OPEN UP! PROJECT," a project aimed at realizing a more prosperous society through innovation by confronting various issues, Seadling Pte. Ltd., a Singaporean startup company focusing on sustainable seaweed farming and the development of seaweed functional ingredients. Through this investment, together with Seadling and other co-creation partners, we will contribute to the establishment of a seaweed supply chain and the expansion of its applications. In addition, we will contribute to building a sustainable marine environment in Asia.

[July 22, 2024 Press Release] Invested in Seadling, which is developing sustainable seaweed farming and functional ingredients in Southeast Asia

Forest management initiatives

Participating in "Hokkaido Corporate Forest Creation"

Nippon Tokan Package is participating in the Hokkaido Corporate Forest Creation initiative being promoted by the Hokkaido Prefectural Government. With the cooperation of the Numata Town Office in Hokkaido, we leased approximately 0.5 hectares of forest in Numata Town, named it "DANDAN Forest," and began forest development activities in September 2023.

In fiscal 2024, employees from across the country spent four months from June to September cutting down trees and building fences and fire pits for sheep farming, engaging in activities that allowed them to interact with nature.

Participating in the "Town, Forest and Water Exchange Meeting"

Toyo Kohan Kudamatsu Plant is committed to forest conservation activities, taking into consideration the prevention of global warming and the importance of water. In October 2023, the plant participated in the 27th Town, Forest and Water Exchange Meeting, sponsored by the Shunan Agriculture, Forestry and Fisheries Office of Yamaguchi Prefecture, which was held at Fureai no Mori, located upstream of Sugano Dam in Shunan City, Yamaguchi Prefecture, the source of industrial water used by the Kudamatsu Plant. Approximately 200 volunteers from companies in Yamaguchi Prefecture and the Shunan region participated in this event. At the exchange meeting, volunteers used saws and other tools to cut down shrubs and remove dead trees, working to maintain the forest.

Biodiversity certification

JHEP Certification

At Toyo Seikan Group 's headquarters building, Osaki Forest Building, we are developing an "urban forest" that forms a green network in cooperation with the surrounding area. In March 2012, Osaki Forest Building received an AA rating under the Japan Habitat Evaluation and Certification Program (JHEP Certification), a system run by the Ecosystem Conservation Society-Japan, a public interest incorporated foundation, which objectively evaluates and certifies efforts to conserve and restore biodiversity. After undergoing renewal in 2017, the building underwent a second renewal in September 2022.

About JHEP Certification (Website of the Ecosystem Conservation Society-Japan, a public interest incorporated foundation) JHEP認証において評価されたポイント 大崎フォレストビルディングに対するJHEP認証審査レポート