Toward a Zero-Waste Society

Basic Perspective

Toyo Seikan Group 's business involves manufacturing packaging containers, steel plates, and other products by processing raw materials made from non-renewable resources such as metals and petroleum. Therefore, it is the Group's major mission to make effective use of resources, such as reducing input materials and reducing and recycling generated waste. In particular, a survey of household waste composition conducted by the Ministry of the Environment in fiscal 2023 * found that packaging waste accounts for 63.6% by volume.

Under the Eco Action Plan 2030, we are working to achieve a circular economy by reducing the use of non-renewable resources by 30%. In addition to our existing efforts to reduce the weight of our packaging, we are also actively promoting the use of recycled materials. Increasing the use of recycled materials in metal cans and increasing the use of recycled materials and plant-based resins in plastic packaging will not only help us achieve the goals of the Eco Action Plan 2030, but also help resolve social issues. These activities not only contribute to the efficient use of resources, but also to reducing the energy used in material production, making them important initiatives in terms of combating global warming. We are also working to develop product designs that are more suitable for sorting and to create systems that promote the collection of used packaging, thereby contributing to the realization of a circular economy.

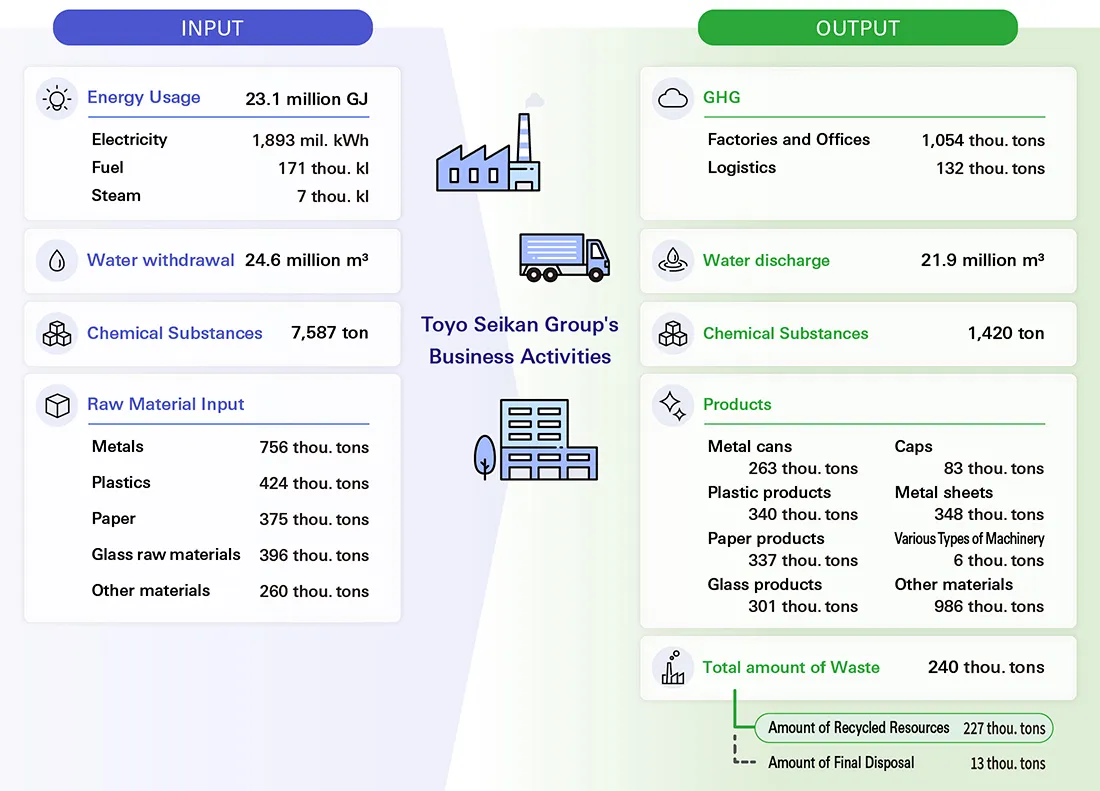

Environmental impact of business activities

Toyo Seikan Group strives to understand the overall material balance and works to reduce its environmental impact.

Toyo Seikan Group Material Flow (FY2024)

- The image can be scrolled left and right

Amount of Industrial Waste Produced from Plastic Products

In accordance with the Act on Promotion of Resource Recycling Related to Plastics, Toyo Seikan Group manages the emissions of industrial waste from plastic products and strives to reduce and recycle them.

*The table can be scrolled left and right.

| Emissions (tons) | |||

|---|---|---|---|

| FY2022 | FY2023 | FY2024 | |

| Toyo Seikan Group Holdings | 50 | 57 | 55 |

| Toyo Seikan | 2,909 | 2,933 | 3,596 |

| Toyo Kohan | 2,057 | 2,189 | 1,898 |

| Tokan Kogyo | 402 | 500 | 366 |

| Nippon Closures | 155 | 135 | 99 |

| Mebius Packaging | 504 | 223 | 235 |

| TOYO GLASS | 111 | 116 | 110 |

| Toyo Aerosol Industry | 166 | 137 | 146 |

| TOMATEC | 238 | 261 | 191 |

| Total | 6,592 | 6,551 | 6,694 |

Sustainable Packaging

Packaging has played an important role in protecting products and facilitating their transportation and storage. It also provides consumers with product information and stimulates their desire to purchase. However, most packaging to date has been disposable, placing a significant burden on the environment. Going forward, it will be important to reduce the environmental impact. To achieve sustainable packaging, the use of renewable materials, promotion of recycling, and weight reduction are required. It is also essential that companies and consumers work together to make environmentally conscious choices. In order to sustain economic activity while protecting the global environment, our Group is working to develop sustainable packaging.

Reduce: Efforts to reduce the weight of containers

Toyo Seikan Group has been working to reduce the weight of its containers in order to cut down on the amount of materials used. By making containers lighter, we can reduce the amount of non-renewable resources used, such as the steel and aluminum used in metal cans and the petroleum used in PET bottles. The Group continues to strive to make effective use of limited resources while maintaining and improving the ease of use of its containers and the quality that protects their contents.

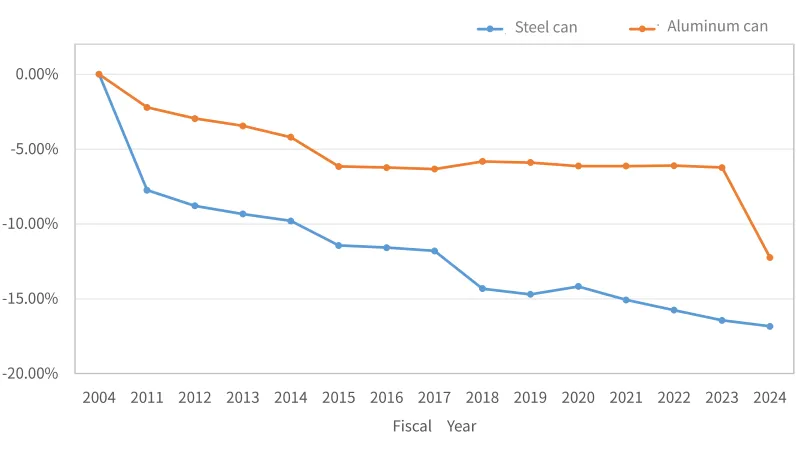

Steel and aluminum beverage cans

The weight of steel and aluminum beverage cans is being reduced by using thinner steel and aluminum plates. Steel beverage cans have been reduced in weight by approximately 16% compared to fiscal 2004, while aluminum cans have been reduced in weight by approximately 12%. The main factor behind the significant improvement in the weight reduction rate for aluminum cans in fiscal 2024 is the adoption of Compression Bottom Reform (CBR).

Trends in weight reduction rates for steel and aluminum beverage cans *

- *Weighted average value of all beverage cans manufactured by Toyo Seikan, transition of weight reduction rate based on the weighted average value in 2004

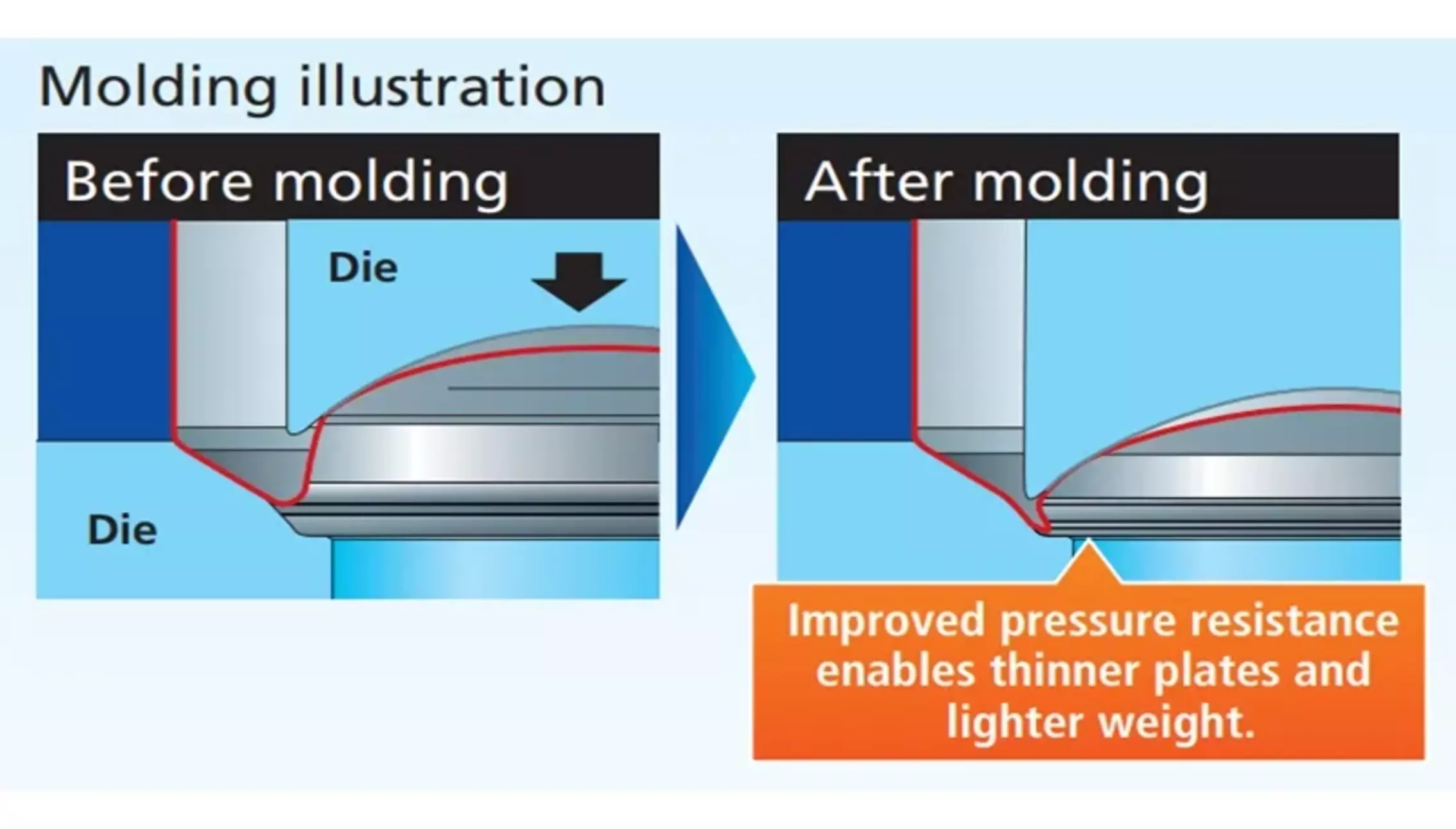

Lightweight aluminum cans made possible by CBR (Compression Bottom Reform

Toyo Seikan has realized the development of aluminum beverage cans using Compression Bottom Reform (Compression Bottom Reform (CBR)), which allows for weight reduction by remodeling and strengthening the bottom of beverage cans. This technology is used for aTULC can diameter 202 diameter (190 ml) and aluminum DI can diameter 211 diameter (350 ml and 500 ml). As a result, it is possible to reduce the weight compared to conventional aluminum beverage cans.

For more information, please see the press release below.

PET bottles

PET bottles for beverages and seasonings use less resin through innovative design shapes and molding conditions.

An environmentally friendly PET bottle that is easy to use and dispose of (jointly developed with Kagome Co., Ltd.)

This lightweight PET bottle features a new design that combines Toyo Seikan 's usability and environmental friendliness. It is 31g to 28g (7%) lighter than the previous model. It is also made from 100% recycled PET material, which is environmentally friendly.

Easy-to-use and easy-to-dispose environmentally friendly PET bottle product page

Coca-Cola🄬 500ml r-PET 100% Lightweight Bottle [Developed in collaboration with Coca-Cola Japan Co., Ltd.]

Toyo Seikan changed the shape of the preform (an intermediate product) and the petaloid shape of the bottle bottom, reducing the weight of only the bottom part. This enabled the company to reduce the weight by 2g (9%) from 23g to 21g while maintaining the same performance and design as conventional containers.

[Press Release, October 24, 2024] Toyo Seikan 's "Coca-Cola🄬 500ml 100% r-PET Lightweight Bottle" and "Ultra-Lightweight Aluminum Beverage Can" Win the 48th Kinoshita Award - Technological innovation that achieves weight reduction contributes to further reducing environmental impact -

Glass bottle

Universal Design Bottle

The ultra-lightweight returnable milk bottle, one of TOYO GLASS' Universal Design Bottle, is a glass bottle designed from an ergonomic perspective to improve ease of holding and pouring. By using a narrowed body and special coating technology, we have achieved a weight reduction of 180g (approximately 40%) from the conventional bottle's weight of 460g to 280g.

Universal Design Bottle Product Page

Cap

Milk Cap for PET Bottles

This is a small, lightweight resin cap for Nippon Closures 's PET bottles for milk. By adjusting the outer diameter and thickness of this cap, we have achieved a resin reduction of approximately 39% by reducing the weight of this product to 1.35g compared to the conventional product's 2.20g.

Milk Cap for PET Bottles product page

Reuse: Initiative to reuse containers

You can reduce waste by thoroughly cleaning containers and reusing them multiple times.

Standardized returnable bottles "R mark bottles"

Plastic container and refill film pouch

Reusable bottles

Recycle: Initiative to reuse containers

Reusing used containers as raw materials helps conserve resources. Toyo Seikan Group is a member of recycling organizations for each material related to our Packaging Business and actively participates in the activities of these organizations, including their management. We also widely promote recycling through the design and development of containers that are easy to separate, and by participating in The Museum of Package Culture and exhibitions.

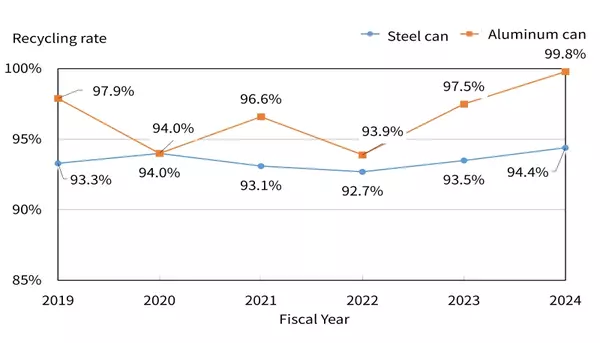

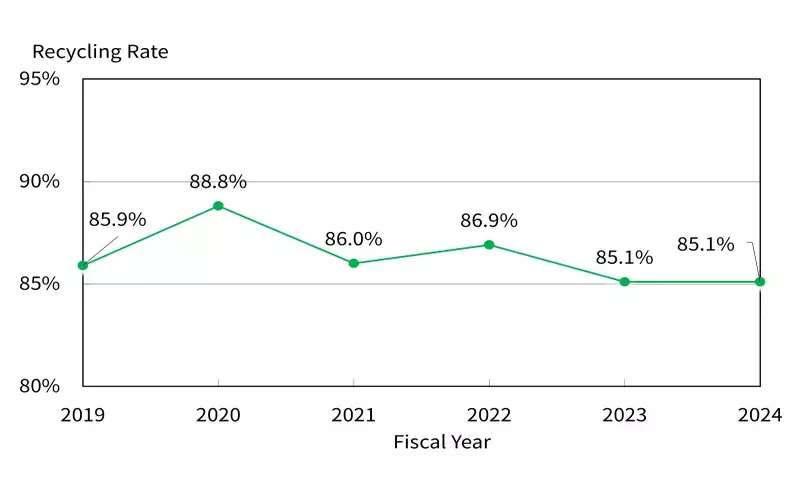

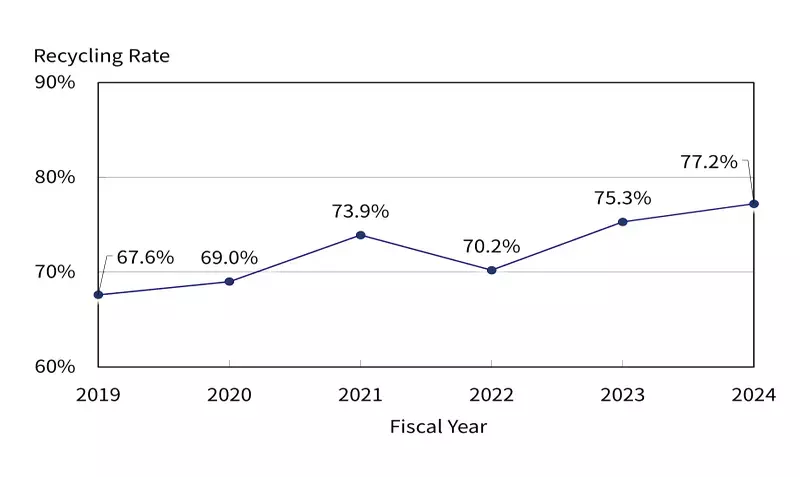

Trends in domestic recycling rates by item [Reprinted from data published by various organizations]

Steel cans *1, aluminum cans *2

PET bottles *3

Glass bottle *4

- Steel Can Recycling Association: The Voluntary Action Plan 2025, which begins in fiscal 2021 and has a target year of fiscal 2025, aims to maintain a numerical target of "maintaining 93% or higher"

- Aluminum Can Recycling Association: Maintain recycling rate of 92.0% or higher as target in Voluntary Action Plan 2025

- PET Bottle Recycling Promotion Council: "Voluntary Action Plan for Promoting 3Rs 2025" Maintain a recycling rate of 85% or more

- Glass Bottle 3R Promotion Council: 2025 target recycling rate of 70% or more

EcoEnd™, a can lid made from recycled materials with a low environmental impact

Toyo Seikan has collaborated with UACJ Corporation to develop "EcoEnd," a lid for beverage cans. Because the aluminum strength and other properties required for can lids and can bodies differ, it was previously necessary to add a certain amount of virgin metal to the lid and adjust its composition. However, with the development of "EcoEnd," it has become possible to use many recycled materials in can lids, which was previously difficult, by adjusting the composition after melting and using innovative manufacturing techniques. Furthermore, because "EcoEnd" significantly increases the amount of recycled material used, it can significantly reduce GHG (greenhouse gas) emissions during raw material production.

[Press Release, December 4, 2023] Development of EcoEnd™, a Next-Generation Environmentally Friendly Beverage Can End Through Major Revisions to Materials and Manufacturing Methods -Toyo Seikan and UACJ Jointly Initiative Reduces Greenhouse Gas Emissions by 40% - 【2024年7月9日プレスリリース】温室効果ガス排出量を4割削減する次世代の飲料缶蓋「EcoEnd™」生産体制の構築を完了-UACJと東洋製罐の共同の取り組み-

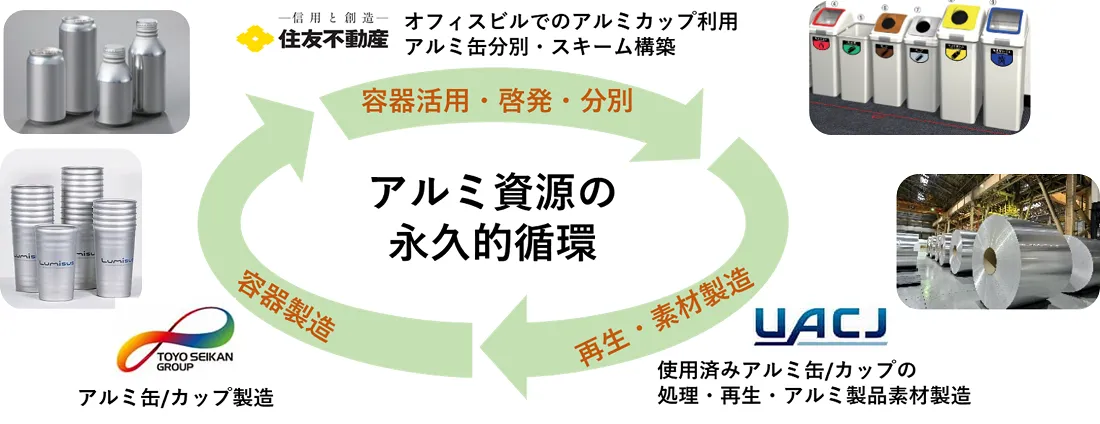

Building a supply chain for horizontal aluminum can recycling to realize a recycling-oriented society

Toyo Seikan Group Holdings, Sumitomo Realty & Development Co., Ltd. (hereinafter "Sumitomo Realty & Development"), and UACJ Corporation (hereinafter "UACJ") have jointly built a "horizontal recycling" supply chain that recycles used aluminum cans into raw materials and reuses them in aluminum can manufacturing.After a test operation in 2023, the system began operation in April 2024, starting from an office building in Tokyo owned by Sumitomo Realty & Development.

In this newly established supply chain, aluminum cans discarded from office buildings owned by Sumitomo Realty & Development undergo a recycling process, are delivered to UACJ plants as recycled raw materials, and are then processed into aluminum plate products.These aluminum plate products are ultimately recycled into aluminum cans and Lumisus® aluminum beverage cups by Toyo Seikan Group.

Furthermore, with the aim of raising awareness of recycling from the bottom up by publicizing this initiative among office users, Sumitomo Realty & Development plans to introduce and use Lumisus® as outdoor drinking cups, starting with cherry blossom festivals at offices operated by the company, and to implement horizontal recycling under the same scheme as aluminum cans. All new aluminum ingots are imported and tend to be susceptible to the effects of international situations. By realizing horizontal recycling, we will promote the replacement of new aluminum ingots with recycled ingots, contributing to the domestic circulation of valuable resources and the reduction of greenhouse gas emissions.

Conceptual diagram of horizontal recycling scheme

Towards the realization of horizontal recycling of PET bottle caps

Nippon Closures Co., Ltd., and Sojitz Pla-Net Corporation began a joint technology verification initiative on January 12, 2023, with the aim of realizing horizontal recycling of PET bottle caps. The consortium is developing a cap collection scheme, verifying the technology, establishing quality standards, and evaluating the business feasibility.

[Press Release, January 12, 2023] Consortium Launched to Realize "Cap to Cap" Horizontal Recycling of PET Bottle Caps

Initiatives to obtain Mass Balance certification

- In the processing and distribution process from raw materials to products, when raw materials with certain characteristics are mixed with raw materials without those characteristics, a method of allocating those characteristics to a portion of the produced product according to the amount of raw materials with those characteristics added.

- ISCC (International Sustainability and Carbon Certification) is an international certification related to sustainability and carbon, and ISCC PLUS is a system that manages and guarantees biomass-based and renewable raw materials and products sold worldwide in the supply chain.

[ISCC PLUS Requirements Declaration]

In accordance with the latest ISCC regulations, Toyo Seikan Group promises and declares that it will comply with ISCC PLUS requirements and will not double-count its environmental contributions.

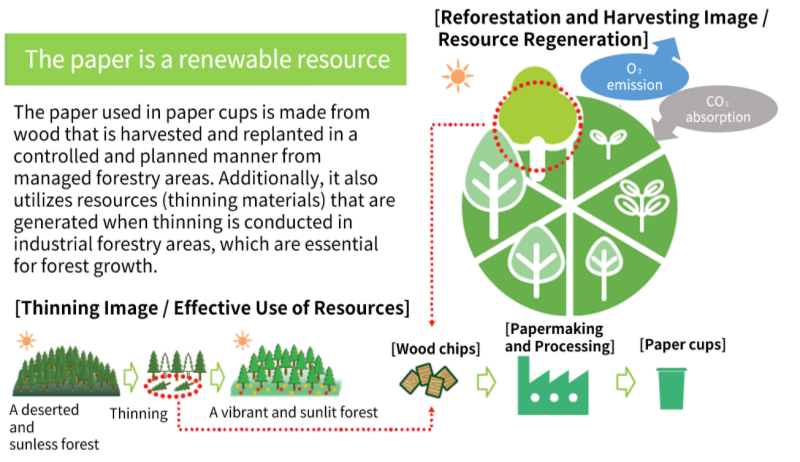

Sustainable use of paper resources

Tokan Kogyo manufactures and sells paper cups made from thinned wood. Thinning involves cutting down some trees to encourage the growth of the remaining trees and protect the health of the forest, and this wood is called thinned wood. By using thinned wood, we contribute to forest conservation and achieve sustainable resource use.

Initiatives to develop the cup washing machine "Re-CUP WASHER"

Tokan Kogyo is promoting efforts to recycle paper cups into recycled cups through the "CUP TO CUP Recycling System," which uses the cup washer "Re-CUP WASHER." In fiscal 2023, we implemented the following initiatives. We will continue to promote the deployment of Re-CUP WASHER and contribute to the realization of a circular economy.

[May 18, 2023 Press Release] Paper Cup Recycling Demonstration Experiment at the G7 Hiroshima Summit International Media Center (IMC) - Utilizing the "Re-CUP WASHER" Cup Washing Machine to Achieve a Circular Economy 【2024年1月31日プレスリリース】東罐興業がカップ洗浄機「Re-CUP WASHER(リカップウォッシャー)」の提供体制を構築~2024年1月より本機の販売・レンタル・リースを開始~ 【2024年2月21日プレスリリース】東罐興業が「宮島夜市」でカップ洗浄機「Re-CUP WASHER(リカップウォッシャー)」を用いて使用済みカップを回収し、リサイクルに繋げる啓発活動に参加 ~サーキュラーエコノミーの実現に向けて広島女学院大学・㈱シンギとの共同実施~Participating in the initiative

Toyo Seikan Group, consisting of 12 companies that make up the plastic value chain, has established R Plus Japan Co., Ltd., a joint venture company that works on the recycling of used plastics to contribute to solving plastic issues and realizing a sustainable society, and began operations in June 2020. Through its participation in R Plus Japan, the company will support efforts to develop efficient recycling technologies for used plastics that have a low environmental impact and to put them into practical use in Japan.

[News dated September 30, 2024] Additional investment in R Plus Japan Co., Ltd., a company engaged in the recycling of used plastics

Compliance with the Containers and Packaging Recycling Law

Toyo Seikan Group, as a specified business operator under the Containers and Packaging Recycling Law, pays a recycling commission fee to the Japan Containers and Packaging Recycling Association every year with the aim of contributing to the realization of a recycling-oriented society. For details of this system, please refer to the Japan Containers and Packaging Recycling Association website.

Japan Containers and Packaging Recycling Association websiteGarbage White Paper

To analyze consumers' environmental awareness and the current state of waste sorting, we will be conducting a "Packaging Recycling Awareness Survey" every year starting in fiscal 2024 and compiling the results into a Waste White Paper.Group and operating company initiatives

Initiatives for fiscal 2024

The opening event for "Zero Waste Fest 2024" will be held on May 3rd (Garbage Day)

In collaboration with the Takizawa Gomi Club, presided over by Machine Guns Takizawa, a comedian and garbage collector, Toyo Seikan Group held a public opening event at our company (Osaki Forest Building) on Friday, May 3, 2024 (national holiday), the first day of Zero Waste Fest 2024.

This year's theme was "Garbage x Art," and we aimed to create an event that not only raised awareness of the SDGs, but that could be enjoyed by people of all ages through art made from garbage. On the day of the event, we held a variety of garbage-related events, such as talk events and workshops, to help people feel closer to the SDGs, and many people, including local residents and those interested in environmental issues, attended.

Changed shipping packaging to returnable, reusable wooden boxes

To reduce waste, Stolle Machinery do Brasil Industria e Comercio Equipamentos Ltda. worked with its suppliers to replace disposable packaging, such as cardboard boxes, used during shipping with returnable wooden boxes. This not only significantly reduces waste, but also contributes to a circular economy by allowing the durable wooden boxes to be reused.