Respect for Employees:Health and Safety Initiatives

Toyo Seikan Group is proactively engaged in health and safety activities to ensure that all parties involved work in a safe and healthy environment, including not only employees but also external stakeholders, partner companies, and contractors.

Our safety activities are carried out mainly through committees organized by each company. These include workplace safety patrols, preventing the recurrence of similar accidents, and risk prediction activities, all of which are carried out continuously based on an activity plan.

In our health activities, we focus on preventing lifestyle-related and occupational diseases, promoting mental health measures, and other areas in accordance with our annual activity plan.

Furthermore, together with our partner companies and contractors, we carry out safety activities and disaster prevention events at our workplaces. Through these efforts, we aim to create a working environment where everyone can work with peace of mind.

Occupational Safety and Health Policy

Toyo Seikan Group clearly defines its "comfortable working environment" in the "Toyo Seikan Group Code of Conduct," and is working to create a workplace where all people can work with peace of mind.

Each operating company strives to ensure and improve the health and safety of employees and takes the necessary measures to create a safe and comfortable workplace based on labor agreements concluded with labor unions and work regulations.

Occupational safety and Health Systems of Each Group Company

At each domestic operating company of Toyo Seikan Group, the Central General Safety and Health Officer (a director or executive officer) appointed by the president appoints a general safety and health manager at each site. The general safety and health manager at each site establishes a safety and health committee and builds a safety and health management system at the site.

The Health and Safety Committee at each site is an organization that promotes safety and health management, and holds a joint health and safety committee meeting once a month with labor and management.

In accordance with the law, the committee is composed of the general safety and health manager, safety managers, health managers, industrial physicians, and members from both the company and the labor union. Half of the members are appointed based on recommendations from the labor union. If any major safety and health issues or concerns are discovered, they are promptly reported to the general safety and health manager, who issues instructions for corrections and countermeasures to the Safety and Health Committee Secretariat, which works with the relevant departments to make improvements, and the details of these improvements are then rolled out to other bases.

Toward the Prevention of Occupational Accidents

To prevent workplace accidents, the central health and safety manager at each company formulates an annual activity plan for each company and carries out the following activities.

As part of our safety activities, we hold a "Safety and Health Committee" every month at each site, and strive to reduce risks by continuously and proactively carrying out activities such as formulating policies suited to the characteristics of the business site, conducting workplace safety patrols, taking measures to prevent the recurrence of similar accidents, and engaging in KY (hazard prediction) activities.We also share safety information with our partner companies, such as examples of industrial accidents and countermeasures, and work together to promote safety activities.As for health activities, we are working to prevent lifestyle-related diseases and occupational diseases, and to promote mental health measures.

We also operate a system for collecting information on near misses, defects, and improvement suggestions from employees.

Occurrence of Occupational Accidents

Number of disasters, injuries, and deaths

| Item | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

| Number of work-related accidents | 69 items | 46 items | 89 items |

| Number of people injured in work-related accidents | 54 people | 41 people | 78 people |

| Number of fatalities among injured | 0 people | 0 people | 0 people |

- Scope of calculation: Toyo Seikan Group Holdings, Toyo Seikan, Toyo Kohan, Tokan Kogyo, Nippon Closures, Mebius Packaging, TOYO GLASS, Toyo Aerosol Industry, TOMATEC

Frequency rate/severity rate

- The table can be scrolled left and right

| Item | Subject | FY2022 | FY2023 | FY2024 |

|---|---|---|---|---|

| Frequency rate *1 | Toyo Seikan Group Holdings and its domestic consolidated subsidiaries | 1.72 | 1.09 | 1.31 |

| Total surveyed industries *4 | 2.06 | 2.14 | 2.10 | |

| Manufacturing industry *4 | 1.25 | 1.29 | 1.30 | |

| Strength rate *2 | Toyo Seikan Group Holdings and its domestic consolidated subsidiaries | 0.02 | 0.05 | 0.06 |

| Total surveyed industries *4 | 0.09 | 0.09 | 0.09 | |

| Manufacturing industry *4 | 0.08 | 0.08 | 0.06 | |

| Coverage rate of the entire group within the scope of calculation *3 | 69% | 69% | 69% | |

- Frequency rate: Number of fatalities and injuries due to work-related accidents resulting in absence from work for one day or more and loss of a part of the body or function / total number of actual working hours x 1,000,000

- Severity rate: Total number of work days lost / Total number of actual working hours x 1,000

- Coverage rate calculated using the number of employees as of April 1st of each year

- Source: Ministry of Health, Labor and Welfare Work Accident Trend Survey Results

Initiatives by Operating Companies

Initiatives for fiscal 2024

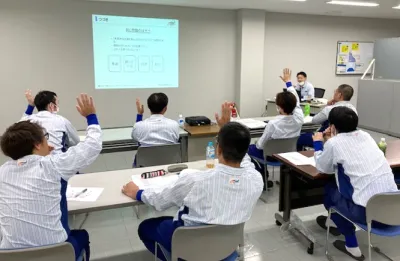

Conducting foreman training by on-site supervisor safety and health training trainers

Toyo Seikan has been conducting foreman training by its own plant's RST trainers (Ministry of Labor-sponsored on-site supervisor safety and health training trainers) since 2020. Seven employees from the Shizuoka Plant, Toyohashi Plant, and Shiga Plant took part in the foreman training held in August 2024, learning about the roles and responsibilities of foremen under the Industrial Safety and Health Act.

CRT driving aptitude test

Nippon Closures Hiratsuka Plant conducted a CRT driving aptitude test in January 2025 with the aim of preventing traffic accidents involving employees. The CRT driving aptitude test is a psychological test that measures behavioral function characteristics such as reaction speed, maintaining appropriate mental tension, and attention allocation and balance, and diagnoses the level of driving aptitude and characteristics and problems of driving behavior, thereby supporting the practice of safer complementary driving behavior. 14 employees participated in the test.

Selected for Kawasaki City's "2024 Joint Safety Awareness Patrol"

Mebius Packaging Kawasaki Factory has been selected as a business to be visited in the "2024 Joint Safety Awareness Patrol" conducted by Kawasaki City and the Kawasaki South and North Labor Standards Inspection Offices. The "2024 Joint Safety Awareness Patrol" was carried out in November 2024 with the aim of raising awareness of collaborative efforts to prevent workplace accidents and promoting workplace accident prevention efforts among businesses in Kawasaki City and reducing workplace accidents by collecting and publishing good practices. The Kawasaki Factory was selected as a business to be visited for this initiative after receiving the Kanagawa Labor Bureau Director's Award at the "2023 Kanagawa Labor Bureau Safety and Health Awards Ceremony" and being recognized as a business with excellent safety and health activities.

For more details about this initiative, please visit the Kawasaki City website.

Safety seminars held

TOYO GLASS Chiba Factory held a safety seminar in May 2024. We invited Tajima Instructor from the Tajima Safety and Health Office to give a lecture on key points to prevent human error. We will use what we learned this time to review our daily education and workplace culture, aiming to become a zero-accident factory.

Heatstroke prevention seminar held

In May 2024, TOYO GLASS Chiba Factory invited Instructor Matsui from Otsuka Pharmaceutical Factory, Inc. to hold a heatstroke prevention course. Participants learned about the early symptoms of heatstroke and dehydration, as well as countermeasures and first aid measures.

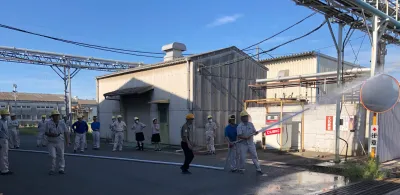

Conduct initial training on firefighting equipment by a firefighting equipment inspection company

The TOMATEC Kyushu Factory received initial training on firefighting equipment from a firefighting equipment inspection company in September 2024. They were given an explanation on how to use fire alarm receivers, indoor and outdoor fire hydrants, firefighting equipment in the pump room, and fire extinguishers, and also conducted actual firefighting training.

Participating in the "Safety Experience Dojo" occupational safety training program

In December 2024, TOMATEC Komaki Factory participated in the "Safety Experience Dojo" occupational safety training program run by TABMEC Corporation. Using actual robots and vehicles, participants learned about the importance of safety. We will continue this program as part of our effective safety education program to achieve zero industrial accidents at the Komaki Factory.

Safety Day event held

Stolle Machinery Company, LLC held a Safety Day event in June 2024 (National Safety Month). To strengthen its efforts toward workplace health and safety, the company provided training on occupational safety and health from an outside instructor, and also conducted activities to improve employee engagement through awards and other means.

Reduce your exposure to harmful substances with welding fume elimination equipment

Stolle EMS Polska Sp. z o.o. continuously operates advanced welding fume removal equipment with highly efficient filters, which significantly reduces exposure to harmful substances generated during the welding process. We are committed to maintaining a safer and healthier working environment and to continuously managing the health of our employees and the hygiene of our work areas.

Conducting training on work equipment operation

To reduce the risk of accidents, Stolle EMS Polska Sp. z o.o. provided employees with training on the operation of overhead cranes, forklifts, work platforms, etc. Employees who participated in this training were given internal certification.

Conducting training on occupational safety and health

Stolle Asia Pacific Co., Ltd. provides occupational health and safety training to all employees throughout the year. As a result of these efforts, there were no occupational accidents or safety violations in 2024.